What is Ball Mill Media? A ball mill is a type of grinding device, designed to grind or mix materials like ores, chemicals, ceramic raw materials, and paints. This cylindrical machine rotates around a horizontal axis and is partially filled with the material to be ground, along with a grinding medium. The grinding media can...

Effective Ball Mill Media for Superior Black Powder Production

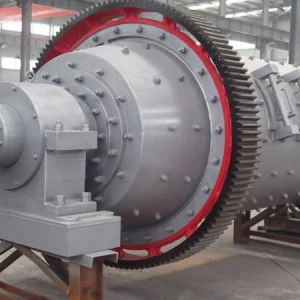

What is Ball Mill Media? A ball mill is a type of grinding device, designed to grind or mix materials like ores, chemicals, ceramic raw materials, and paints. This cylindrical machine rotates around a horizontal axis and is partially filled with the material to be ground, along with a grinding medium. The grinding media can...

what is a ball mill used for

what is a ball mill used for? A ball mill is a type of grinder used to grind and blend materials for use in various industries and applications. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A...

What is a ball mill? 0 to 100 ball mill reviews

what is a ball mill? In response to the question what is a ball mill it should be said, A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition:...

Top 10 Best Mills for Efficient Grinding:Reviewo & Buying Guide2024

The top 10 best ball mills for efficient grinding in 2024 are renowned for their performance, reliability, and innovative features. These include the Fritsch Planetary Ball Mill, Retsch High Energy Ball Mill Emax, Union Process Attritor Mill, RETSCH PM 100 Planetary Ball Mill, SPEX SamplePrep 8000M Mixer/Mill, Fritsch Pulverisette 7 Premium, RETSCH PM 200 Planetary...

description of ballmills in other materials

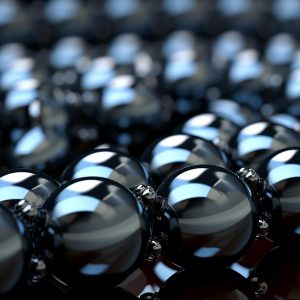

Ball milling utilizes various materials such as ceramic balls, flint pebbles, and stainless steel balls as grinding media.These are selected to effectively pulverize and diminish particle sizes during processing. Ceramic balls are favored for their exceptional hardness and wear resistance. Flint pebbles, composed of silica, are prized for their minimal contamination and superior grinding capabilities....

Mining Balls: The Backbone of Material Processing

Mining balls come in a variety of types, including grinding balls, steel grinding balls, forged steel grinding balls, and rolled grinding balls.They are essential elements within the mining sector. These robust, meticulously engineered spheres are crucial for pulverizing and milling raw materials, aiding in the effective processing of materials and the extraction of resources.In this...

Different sizes of mill balls

Ball mills are essential equipment in many industrial processes, particularly in the mining and mineral processing industries, where they are used for grinding materials into fine powder. The efficiency and effectiveness of a ball mill largely depend on the size and type of grinding media (balls) used. Understanding the sizes of ball mill balls and...

Selection of the highest quality grinding balls

In the intricate choreography of ball milling, where raw materials undergo a metamorphosis into finely milled particles, the choice of grinding media emerges as a critical performance determinant. Despite its seemingly modest role, the selection of grinding media exerts a profound influence on the efficiency, output quality, and ultimately, the bottom-line impact of the milling...

Benefits of charging DRI in steel making furnace

We explain the advantages of DRI charging in steelmaking furnace in this section. Advantages of Utilizing Direct Reduced Iron (DRI) in Steel Production Furnaces Advantages of Utilizing Direct Reduced Iron (DRI) in Steel Production STORAGE, HANDLING AND LOADING OF DRI Thermocouples are strategically positioned for surveillance throughout the journey (TC1 to TC5). Once 50-100% of...

- 1

- 2