Steel grinding balls are fundamental to various industrial processes, serving as a critical media for size reduction and material processing in ball mills12. These specialized balls are engineered to effectively crush and grind materials into fine powders in dry environments or pulp in wet environments3. Their operation relies on the principle of impact and attrition,...

Category: <span>ARTICLES</span>

Introducing the differences between ceramic balls and steel balls

Steel balls, also known as bearing balls or ball bearings, are used across a wide range of industries due to their exceptional durability, high strength, and corrosion resistance. These characteristics make them indispensable in various manufacturing processes and mechanical systems. In this article, we will explore the different types of steel balls and their specific...

Introducing different types of caustic soda

Caustic soda, also known as sodium hydroxide (NaOH), is a highly corrosive and versatile chemical compound made up of sodium cations (Na+) and hydroxide anions (OH-). This compound is widely recognized by various names, including lye, caustic soda, sodium hydroxide hydrate, and soda lye. It plays a vital role across many industries, such as gas,...

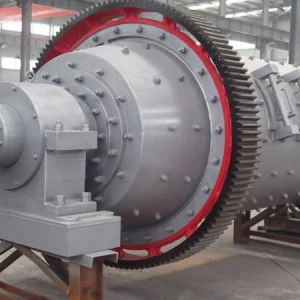

Types of Ball Mills: A Comprehensive Guide to Their Uses and Benefits

Ball mills are crucial equipment in various industrial processes, including material grinding, mixing, and even the production of fine powders. Their versatility and efficiency make them indispensable in industries ranging from mining and metallurgy to pharmaceuticals and chemicals. The main function of ball mills is to reduce the size of solid materials through a grinding...

Effective Ball Mill Media for Superior Black Powder Production

What is Ball Mill Media? A ball mill is a type of grinding device, designed to grind or mix materials like ores, chemicals, ceramic raw materials, and paints. This cylindrical machine rotates around a horizontal axis and is partially filled with the material to be ground, along with a grinding medium. The grinding media can...

what is a ball mill used for

what is a ball mill used for? A ball mill is a type of grinder used to grind and blend materials for use in various industries and applications. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A...

What is a ball mill? 0 to 100 ball mill reviews

what is a ball mill? In response to the question what is a ball mill it should be said, A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition:...

Top 10 Best Mills for Efficient Grinding:Reviewo & Buying Guide2024

The top 10 best ball mills for efficient grinding in 2024 are renowned for their performance, reliability, and innovative features. These include the Fritsch Planetary Ball Mill, Retsch High Energy Ball Mill Emax, Union Process Attritor Mill, RETSCH PM 100 Planetary Ball Mill, SPEX SamplePrep 8000M Mixer/Mill, Fritsch Pulverisette 7 Premium, RETSCH PM 200 Planetary...

description of ballmills in other materials

Ball milling utilizes various materials such as ceramic balls, flint pebbles, and stainless steel balls as grinding media.These are selected to effectively pulverize and diminish particle sizes during processing. Ceramic balls are favored for their exceptional hardness and wear resistance. Flint pebbles, composed of silica, are prized for their minimal contamination and superior grinding capabilities....

Mining Balls: The Backbone of Material Processing

Mining balls come in a variety of types, including grinding balls, steel grinding balls, forged steel grinding balls, and rolled grinding balls.They are essential elements within the mining sector. These robust, meticulously engineered spheres are crucial for pulverizing and milling raw materials, aiding in the effective processing of materials and the extraction of resources.In this...