Steel production is a cornerstone of industrial development and modern infrastructure. As the global demand for high-quality steel grows, the use of advanced raw materials such as Direct Reduced Iron (DRI) has become increasingly important. DRI, often referred to as sponge iron, has revolutionized steel-making processes by offering cleaner, more efficient alternatives to traditional methods. This document explores DRI’s role in the steel industry, its benefits, and its impact on production efficiency.

What is DRI and Its Role in Steel-Making?

Definition of DRI (Direct Reduced Iron)

Direct Reduced Iron (DRI) is a product of the direct reduction of iron ore using a reducing gas or elemental carbon. Unlike traditional methods that rely on blast furnaces, DRI is produced at lower temperatures, typically below the melting point of iron, resulting in a solid metallic product with minimal impurities.

Overview of its Usage in Modern Steel Production

DRI is increasingly utilized as a primary feedstock in electric arc furnaces (EAFs) and other steel production furnaces. Its consistent chemical composition, low impurity levels, and controlled carbon content make it a preferred alternative to scrap metal, especially for producing high-quality steel. Furthermore, advancements in hydrogen-based reduction methods have positioned DRI as a key player in the transition towards sustainable steel manufacturing.

Key Benefits of Using DRI in Steel-Making Furnaces

Improved Energy Efficiency and Reduced Fuel Consumption

DRI production requires significantly less energy compared to traditional blast furnace methods. It’s designed for integration into EAFs, reducing the overall energy required for melting and processing. The use of natural gas or hydrogen in DRI production further enhances energy efficiency by lowering the dependency on coal-based processes.

Enhanced Steel Quality with Fewer Impurities

One of the standout advantages of DRI is its minimal impurity content. Unlike scrap metal, which can contain contaminants and undesirable elements, DRI offers a consistent and predictable composition. This leads to higher-quality steel, reduced need for secondary refining, and improved end-product performance.

Lower CO2 Emissions and Environmental Advantages

The adoption of DRI in steel-making significantly reduces carbon emissions. Hydrogen-based reduction methods, in particular, can cut CO2 emissions by up to 95% compared to conventional coal-coke-based methods. This positions DRI as a vital component in achieving global decarbonization goals within the steel industry.

How DRI Impacts Steel Production Efficiency

Faster Melting Times in Electric Arc Furnaces (EAFs)

The uniform size and composition of DRI enable quicker and more consistent melting in EAFs. This reduces overall processing time and increases furnace productivity, allowing for higher throughput and operational efficiency.

Reduction in Slag Formation and Waste Materials

DRI’s low impurity levels contribute to minimal slag formation during the steel-making process. This not only reduces waste but also decreases the time and resources needed for slag management, leading to cleaner operations and better resource utilization.

Consistent Composition and Predictable Performance

The uniform chemical composition of DRI ensures predictable behavior during steel production. This consistency simplifies process control, enhances product quality, and reduces the likelihood of operational disruptions.

Cost Advantages of Charging DRI

Reduction in Raw Material Costs

By using DRI, steelmakers can lower their dependency on expensive and often variable-quality scrap metal. The controlled production of DRI allows for more predictable raw material costs, contributing to overall financial stability.

Lower Maintenance and Operational Costs

The cleaner and more uniform nature of DRI reduces wear and tear on furnace linings and equipment. This leads to lower maintenance costs and extends the operational life of critical steel-making assets, further enhancing cost-effectiveness.

DRI vs. Scrap Metal: Which is Better for Steel-Making?

A Comparison of the Benefits and Limitations of DRI and Scrap Metal

Scrap metal has traditionally been a widely used feedstock in steel-making due to its availability and low cost. However, its variable quality and impurity levels often lead to inconsistent steel production outcomes. In contrast, DRI offers superior quality control, fewer impurities, and more predictable performance, making it a preferred choice for high-grade steel production.

Why DRI is Becoming a Preferred Choice in Many Steel Industries

The growing emphasis on sustainability, energy efficiency, and high-quality steel production has driven many steelmakers to adopt DRI. Its compatibility with advanced technologies like hydrogen-based reduction and electric arc furnaces positions it as a critical component in the future of steel-making.

Environmental Implications of Using DRIv

Contribution to Sustainable Steel Production:

Direct Reduced Iron (DRI) plays a significant role in sustainable steel production by providing an alternative to traditional blast furnace methods. Unlike conventional methods, DRI is produced using natural gas or hydrogen, reducing the need for coking coal. This shift helps reduce the carbon footprint of the steel industry, making it more environmentally friendly. One of the benefits of DRI is its potential to reduce energy consumption and lower carbon emissions compared to the traditional processes. The use of DRI can thus contribute significantly to achieving more sustainable steel-making practices.

Role in Reducing Greenhouse Gas Emissions:

The DRI process offers a crucial advantage in reducing greenhouse gas emissions in steel production. Traditional blast furnaces are major sources of carbon dioxide, but the use of DRI in a steel-making furnace minimizes this emission. By utilizing natural gas or hydrogen, DRI reduces the reliance on coke and minimizes CO2 emissions, leading to cleaner steel production. This shift is essential for the steel industry’s transition to greener methods. Moreover, it aligns with the growing emphasis on environmental sustainability in industrial production.

Challenges and Considerations in DRI Usage

Potential Logistical and Handling Issues:

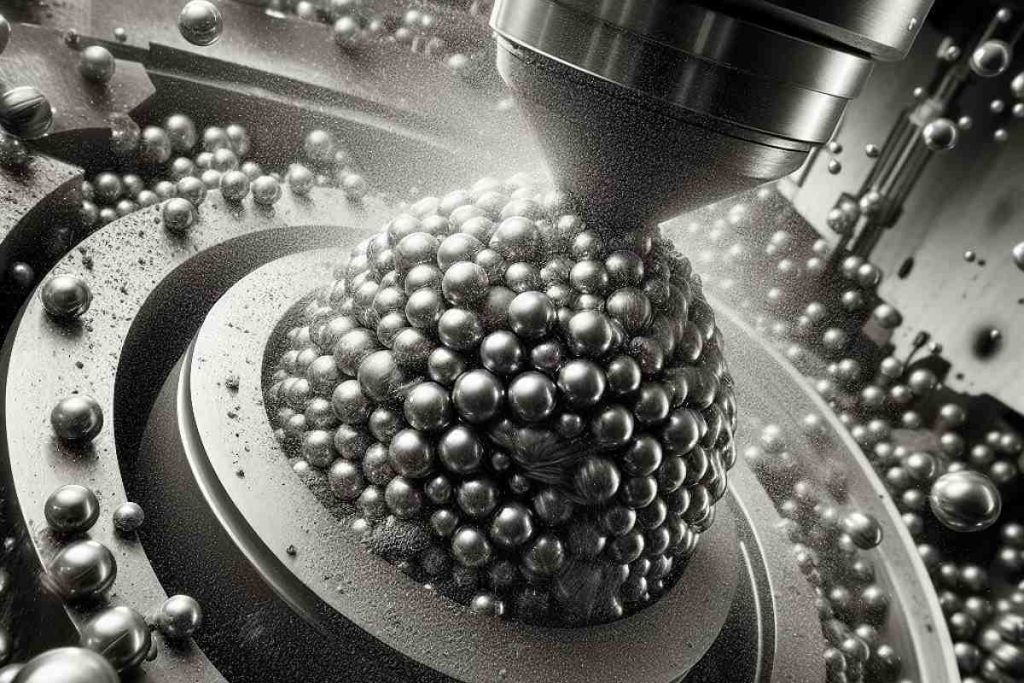

While DRI offers numerous environmental benefits, its usage comes with logistical challenges. Handling and transportation of Steel balls or DRI products require specific infrastructure and processes to maintain quality and prevent issues such as oxidation. DRI is prone to air oxidation, which can compromise its effectiveness in steel-making processes. Addressing these logistical issues is critical to ensuring the smooth integration of DRI into large-scale steel production.

Integration of DRI into Existing Steel-Making Processes:

The successful integration of DRI into current steel production methods presents a technical challenge. Modern steel-making furnaces may require adjustments or modifications to accommodate DRI, which may not seamlessly integrate with traditional processes. While DRI enhances steel production efficiency, existing steel mills need to invest in technologies and adaptations to support this transition. Overcoming these hurdles will be essential for the widespread adoption of DRI in the steel industry.

Future Trends in Steel-Making with DRI

Innovations in DRI Production and Application:

The future of steel-making is closely tied to innovations in DRI production. Advances in hydrogen-based DRI production are expected to revolutionize the steel-making industry by further reducing carbon emissions and improving overall steel production efficiency. Research into more efficient methods of producing DRI will continue to shape the future of steel manufacturing, making it more sustainable and cost-effective. As innovations in the field progress, DRI’s role will expand, making it a key component in green steel production.

The Growing Role of DRI in Green Steel Initiatives:

With an increasing focus on environmental responsibility, the growing role of DRI in green steel initiatives is undeniable. By enhancing steel production efficiency and reducing carbon emissions, DRI is becoming central to the push for carbon-neutral steel manufacturing. As the industry moves towards greener solutions, DRI is expected to play a key role in achieving the steel industry’s sustainability goals, positioning it as a critical material in the production of eco-friendly steel. This growing role of DRI aligns with global efforts to reduce the environmental impact of industrial processes.

. Conclusion on the Benefits of Charging DRI in Steel-Making Furnace

Charging DRI into the steel-making furnace offers numerous advantages that significantly enhance the overall efficiency and sustainability of steel production. The benefits of DRI include reduced carbon emissions, improved steel production efficiency, and a lower environmental impact compared to traditional steel-making methods. By utilizing natural gas or hydrogen instead of coke, DRI offers a cleaner and more sustainable path for steel production, while also contributing to cost savings and better energy utilization. The integration of DRI can lead to greener, more efficient steel-making processes, supporting the global push for environmentally responsible industrial practices.

For those looking to optimize the use of DRI in their steel-making operations, Alpha Grinding Media offers expert consultancy services. Their experience in steel production can help guide the effective incorporation of DRI into existing processes, ensuring maximum efficiency and sustainability.

Frequently Asked Questions (FAQ)

What is Direct Reduced Iron (DRI)?

DRI is a form of iron produced by reducing iron ore using natural gas or hydrogen, instead of using coke in a blast furnace. It is used as a raw material in steel-making processes to create high-quality steel.

How does DRI contribute to reducing carbon emissions in steel production?

By using natural gas or hydrogen instead of coke, DRI significantly reduces the carbon dioxide emissions typically produced in conventional steel-making methods, such as blast furnaces. This makes the steel production process more environmentally friendly.

What are the key advantages of using DRI in steel-making furnaces?

DRI improves steel production efficiency, lowers energy consumption, reduces CO2 emissions, and offers a cleaner alternative to traditional steel production methods. It also helps lower reliance on coking coal, making the process more sustainable.

Can DRI be used in all steel-making processes?

While DRI can be used in many steel-making processes, it requires specific adjustments to existing systems, such as steel-making furnaces. Successful integration depends on technological upgrades and infrastructure to handle DRI efficiently and prevent oxidation or other potential issues.