In the extraction industry, the mine site, itself the open pit or underground workings, often captures the public imagination. However, for industry professionals, the true economic realization of a mining project occurs downstream, within the complex industrial facility known as the Mineral Processing Plant.

Extracting Run-of-Mine (ROM) ore from the earth is merely the preliminary step. This raw material is typically an aggregate of valuable minerals locked within a matrix of economically worthless waste rock, or gangue. The processing plant acts as the critical interface between the mine and the global market, transforming low-grade rock into high-grade concentrate or refined metal.

For operators and metallurgists, the plant is a system of interconnected circuits where efficiency is paramount. Every stage, from the primary crusher to the tailings thickener, must be optimized. In this ecosystem, the role of high-performance consumables—specifically the grinding media provided by industry leaders like Alpha Grinding Media—cannot be overstated, as they dictate the efficiency of the plant’s most energy-intensive processes.

The Core Objective: Beneficiation and Liberation

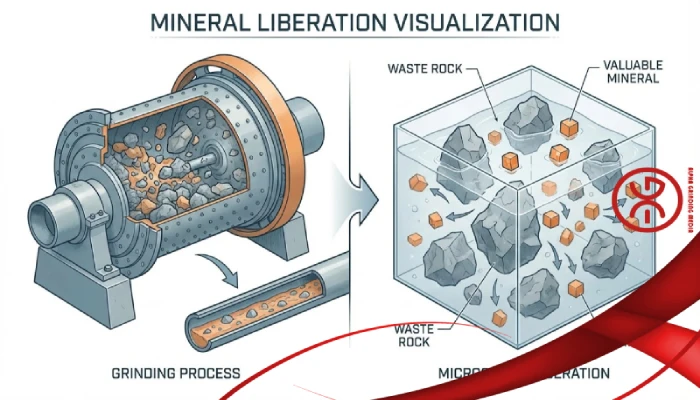

The fundamental purpose of a processing plant is “beneficiation”—the improvement of the ore’s economic value by separating the valuable minerals from the gangue. This process relies on a singular, critical concept: Mineral Liberation.

In its natural state, the target mineral (whether copper, gold, or iron) is physically attached to or encapsulated by the host rock. Before any separation can occur, the ore must be broken down to a specific size where the valuable mineral is sufficiently “free” from the waste.

If the plant fails to achieve adequate liberation, the valuable mineral remains locked inside the waste rock and is lost to the tailings, reducing recovery rates. Conversely, if the rock is pulverized too finely, it generates “slimes” that complicate separation and dewatering. Achieving this precise balance is the primary function of the comminution circuit.

Anatomy of a Processing Plant: Key Operational Circuits

While the specific flowsheet of a plant depends entirely on the mineralogy of the ore body, most modern processing facilities follow a standard operational logic involving three main stages: Comminution, Separation, and Dewatering.

1. Comminution: The Energy-Intensive First Step

Comminution is the process of particle size reduction. It is typically the most expensive stage of processing in terms of energy consumption and operational costs.

- Crushing: The process begins with crushing, a dry mechanical process used to reduce large boulders of ROM ore into coarse gravel. This is achieved using jaw crushers, cone crushers, or gyratory crushers.

- Grinding: Once crushed, the ore enters the grinding circuit, which is usually a wet process. Here, the material is fed into large tumbling mills—such as Semi-Autogenous Grinding SAG mills and Ball Mills.

Inside the Ball Mill, the ore is mixed with water to form a slurry. The reduction in size is achieved through impact and attrition caused by the tumbling action of steel grinding media. This is the specific domain where Alpha Grinding Media operates. The interaction between the steel balls and the ore determines the final particle size distribution (PSD) and the degree of liberation, setting the stage for the success or failure of the subsequent separation phase.

2. Separation: Physical and Chemical Extraction

Once the ore is ground to the optimal liberation size, it moves to the separation circuit. The method used here exploits the differences in physical or chemical properties between the mineral and the gangue.

- Froth Flotation: Widely used for sulphide ores (like copper and zinc). The slurry is mixed with reagents that make the valuable minerals hydrophobic (water-repelling). Air is introduced, and the minerals attach to bubbles, rising to the surface as a mineral-rich froth while the waste sinks.

- Gravity Separation: Utilizes the difference in specific gravity (density). Heavier minerals (like gold or tin) settle faster than lighter gangue minerals in devices like spirals or centrifuges.

- Magnetic Separation: Used primarily for iron ore, where magnetic minerals are separated from non-magnetic waste using powerful magnets.

3. Dewatering and Product Handling

The product of the separation stage is a concentrate slurry, which contains too much water for transport. The dewatering circuit employs thickeners (large settling tanks) and filtration units (pressure or vacuum filters) to remove the water, resulting in a dry, filter cake concentrate. This final product is then stockpiled and shipped to smelters for refining.

The Strategic Importance of Grinding Media in Plant Performance

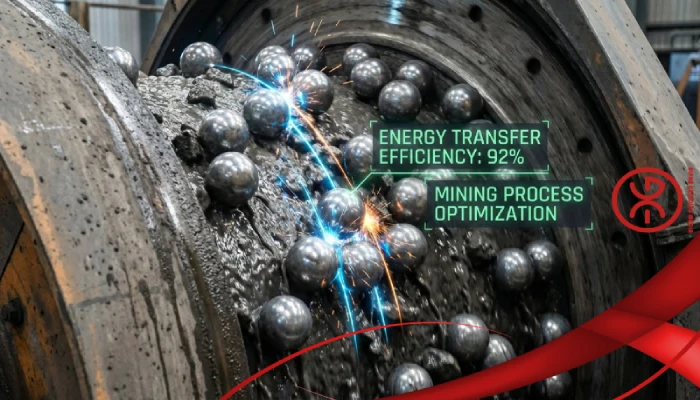

While a processing plant consists of massive infrastructure, its efficiency is often dictated by the smallest components: the grinding media inside the ball mills. For plant managers, selecting the right media is a strategic decision that impacts the entire flowsheet.

Optimizing Grinding Efficiency

The primary role of grinding media is to deliver the kinetic energy required to break the rock. High-quality media, such as that manufactured by Alpha Grinding Media, is engineered for optimal hardness and structural integrity. This ensures that the balls maintain their spherical shape for longer periods. Distorted or broken media fails to grind effectively, leading to a coarser grind and poor mineral liberation. By maintaining a consistent media charge, the plant ensures a consistent throughput and optimal particle size distribution.

Chemical Stability and Pulp Chemistry

In processes like froth flotation, the chemical environment of the slurry (pulp) is delicate. Poor-quality grinding media can experience rapid corrosive wear, releasing excessive iron ions and oxidation products into the slurry. These contaminants can alter the surface chemistry of the mineral particles, reducing the effectiveness of the flotation reagents and lowering overall recovery. Alpha Grinding Media focuses on alloy compositions that resist corrosive wear, preserving the chemical balance of the pulp and protecting downstream recovery rates.

Operational Continuity and OPEX

Media consumption is a significant operating expense (OPEX). High wear rates mean the mill must be recharged more frequently, and the generated debris can block discharge grates or damage pumps. Utilizing durable, high-impact resistant media reduces the frequency of stoppages for maintenance and media replenishment, thereby maximizing the plant’s availability and overall productivity.

Tailings Management: The End of the Line

A discussion on processing plants is incomplete without addressing the waste stream. The material remaining after the valuable minerals have been extracted is known as “tailings.” This slurry is pumped to a Tailings Storage Facility (TSF). Modern plants are increasingly focusing on thickening or filtering tailings (dry stacking) to recover process water and improve the geotechnical stability of the storage facility, minimizing environmental impact

Conclusion: Optimization is the Key to Profitability

A Mineral Processing Plant is not merely a collection of machinery; it is a finely tuned system where the performance of one circuit directly impacts the next. The efficiency of the separation circuit is held hostage by the quality of the grind produced in the comminution circuit.

For mining companies, profitability depends on maximizing recovery while minimizing cost per ton. This requires a holistic approach to plant management, where investing in superior technical solutions—from advanced flotation cells to high-quality consumables like Alpha Grinding Media—ensures that the plant operates at its peak potential, unlocking the full value of the natural resource.

Frequently Asked Questions

1. How does the quality of grinding media affect the downstream separation process?

The quality of grinding media directly influences the Particle Size Distribution (PSD) of the ground ore. High-quality media ensures a consistent grind, achieving the optimal “liberation size” required for separation. Additionally, media with high wear resistance prevents the release of excess iron oxidation products into the slurry, which can otherwise alter pulp chemistry and negatively impact reagent performance in froth flotation circuits.

2. What is the difference between "Comminution" and "Beneficiation"?

“Beneficiation” is the broad term for the overall process of improving the economic value of ore by separating valuable minerals from waste rock. “Comminution” is a specific sub-process within beneficiation (the first stage) that involves reducing the particle size of the ore through crushing and grinding to liberate the minerals before separation can occur.

3. Why is "Mineral Liberation" considered the most critical factor in plant efficiency?

Mineral liberation refers to the degree to which the valuable mineral is physically detached from the gangue (waste rock). If the ore is not ground fine enough to achieve liberation, the valuable mineral remains “locked” within the waste particle. Consequently, the separation equipment cannot distinguish it from the waste, causing it to be lost to the tailings, which significantly lowers the plant’s overall recovery rate.

4. How is the specific separation method (e.g., Flotation vs. Gravity) selected for a plant?

The choice of separation method is dictated by the specific mineralogy and physical properties of the ore body. Gravity Separation is chosen when there is a significant density difference between the mineral and the gangue. Froth Flotation is selected for minerals (typically sulphides) that can be made hydrophobic through chemical conditioning. Magnetic Separation is used for ores containing ferromagnetic minerals like magnetite.