In the mining and mineral processing industry, the extraction of valuable commodities whether gold, copper, or iron ore is inextricably linked to the production of waste. While “waste rock” (overburden) constitutes the material moved to access the ore body, mine tailings represent a more complex challenge. Tailings are the fine-grained residue remaining after the uneconomic fraction is separated from the valuable minerals during the beneficiation process

For mining engineers, metallurgists, and environmental managers, mine tailings management is not merely an operational necessity; it is a critical component of the mine’s lifecycle, financial liability, and social license to operate. The journey of tailings begins at the comminution stage, where the efficiency of grinding media plays a pivotal role, and ends in the long-term stability of storage facilities.

Defining Tailings: Composition and Characteristics

To the uninitiated, tailings might look like mud or sand, but industry professionals understand the chemical and physical complexity of this material. Tailings are distinct from waste rock because they have undergone processing. They are the result of crushing, grinding, and chemical separation.

Physical and Chemical Composition

Physically, tailings are typically a slurry—a mixture of water and fine mineral particles ranging from sand-sized down to silt and clay sizes (often measured by the P80 value). The specific gravity, viscosity, and settling rate of this slurry dictate how it must be pumped and stored.

Chemically, tailings consist of the host rock (gangue) and may contain residual reagents used in the extraction process, such as cyanide in gold processing or sulfuric acid in copper leaching. Furthermore, they may contain uneconomic concentrations of the target mineral or other heavy metals like arsenic, lead, or mercury, which necessitates rigorous containment strategies to prevent environmental contamination.

The Generation Process: From Comminution to Separation

The generation of tailings is the final step of the beneficiation circuit, but its characteristics are determined much earlier, specifically during comminution. This is the stage where ore is reduced in size to liberate the valuable minerals from the gangue.

The Role of Grinding Efficiency

The physical properties of tailings—specifically the particle size distribution (PSD)—are directly influenced by the efficiency of the grinding circuit. This is where the quality of the grinding media becomes paramount.

High-quality grinding media, such as the products manufactured by Alpha Grinding Media, ensure that the ore is ground to the optimal size for liberation without excessive “over-grinding.” Over-grinding produces ultra-fine particles (slimes), which cause significant issues downstream. Slimes are difficult to dewater, slow to settle in thickeners, and can compromise the stability of tailings dams. Conversely, consistent and efficient grinding, achieved through superior media, results in a more predictable tailings product that is easier to handle, pump, and store. Therefore, effective mine tailings management actually begins inside the ball mill.

Standard Methods of Tailings Handling and Storage

Once generated, the tailings must be transported and stored. The method selected depends on the topography, climate, seismic activity of the region, and the physical properties of the tailings.

Conventional Slurry Impoundments

Historically, the most common method of storage is the conventional slurry impoundment. Here, tailings are pumped as a low-density slurry into a dam or pond.

- Mechanism: The solids settle to the bottom, and the supernatant water is decanted and often recycled back to the plant.

- Pros: Lower operational costs (OPEX) and simpler transport via centrifugal pumps.

- Cons: These facilities require large footprints and pose the highest geotechnical risk. The high water content increases the risk of seepage and dam failure.

Paste and Thickened Tailings

To mitigate the risks associated with excess water, many modern operations employ thickeners (high-rate or deep-cone) to increase the solid content of the tailings before discharge.

- Mechanism: Flocculants are added to separate water, creating a non-segregating paste with a consistency similar to toothpaste.

- Advantages: This method recovers significant amounts of process water (crucial in arid regions), reduces the volume of the Tailings Storage Facility (TSF), and improves structural stability.

Dry Stack Tailings

Dry stacking is considered the gold standard for environmental safety and water conservation, though it comes with higher costs.

- Mechanism: Tailings are passed through vacuum or pressure filters to remove the majority of the water, resulting in a filter cake with less than 20% moisture. This material is then transported by truck or conveyor and compacted into a stack.

- Advantages: Eliminates the risk of catastrophic dam failure (as there is no fluid to flow), reduces the footprint, and allows for progressive rehabilitation.

Underground Backfilling

In underground mining operations, tailings can be mixed with cement to create a hydraulic backfill or paste fill. This mixture is pumped back into the mined-out voids (stopes). This serves a dual purpose: it disposes of the waste and provides structural support for the mine, allowing for the extraction of adjacent ore pillars.

Environmental Risks and Geotechnical Challenges

The management of Tailings Storage Facilities (TSF) is one of the most significant risks in the mining portfolio.

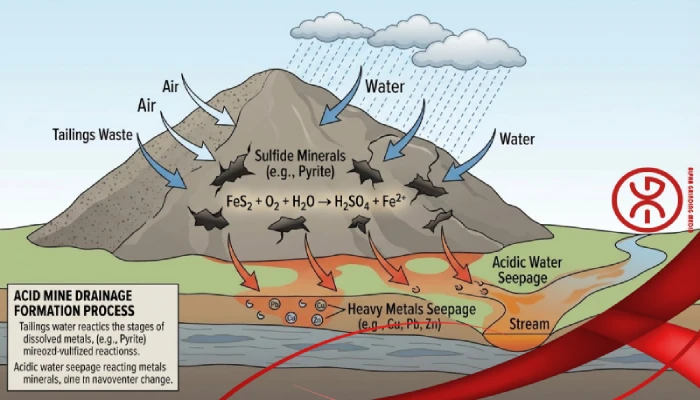

Acid Mine Drainage (AMD) and Leaching

If the tailings contain sulfide minerals (like pyrite or pyrrhotite), exposure to oxygen and water can generate sulfuric acid. This phenomenon, known as Acid Mine Drainage (AMD), can leach heavy metals into the surrounding groundwater and surface water ecosystems. Preventing AMD requires limiting oxygen ingress, often by keeping potentially acid-generating (PAG) tailings submerged under water or capping them with impermeable clay layers.

Structural Integrity and Dam Failures

The failure of a tailings dam can be catastrophic, leading to loss of life and massive environmental damage. Failures are often caused by liquefaction, where the solid tailings behave like a liquid during a seismic event, or by overtopping due to poor water balance management. Following recent high-profile disasters, the industry has adopted the Global Industry Standard on Tailings Management (GISTM), which mandates stricter governance and engineering standards.

Conclusion

Mine tailings management is a multidisciplinary challenge that defines the modern mining industry. It requires a holistic approach that connects the mill to the dam. It starts with optimizing the comminution process using high-performance solutions like Alpha Grinding Media to ensure a favorable particle size distribution, and extends to employing advanced dewatering and storage technologies.

For industry professionals, the goal is clear: to design and operate systems that minimize environmental impact, ensure geotechnical stability, and maximize water recovery, transforming a waste management liability into an engineered asset.

Frequently Asked Questions

1. What is the difference between waste rock and tailings?

Waste rock is the natural rock that covers or surrounds the ore body and is moved to access the ore; it is generally coarse and has not been processed. Tailings are the fine-grained residue left over after the ore has been processed chemically and mechanically to extract the minerals.

2. Why is water management critical in tailings storage?

Water is the primary enemy of TSF stability. Excess water increases pore pressure within the dam, increasing the risk of liquefaction and seepage. Furthermore, recovering water from tailings (through thickening or filtration) reduces the mine’s fresh water withdrawal, lowering operational costs and environmental impact.

3. How does grinding media affect tailings management?

The quality and hardness of grinding media determine the consistency of the grind. Inconsistent or poor-quality media can lead to variations in particle size (P80). If particles are too fine (slimes), dewatering becomes difficult and expensive, and the tailings settle poorly in the dam. Consistent grinding provided by brands like Alpha Grinding Media ensures optimal downstream handling.

4. What is the "P80" value in relation to tailings?

P80 is a metric indicating that 80% of the particles in a sample are smaller than a specified size (e.g., 75 microns). This value is crucial for engineers to design pumping systems, thickeners, and the final storage facility, as it dictates how the material will flow and settle.