what is a ball mill?

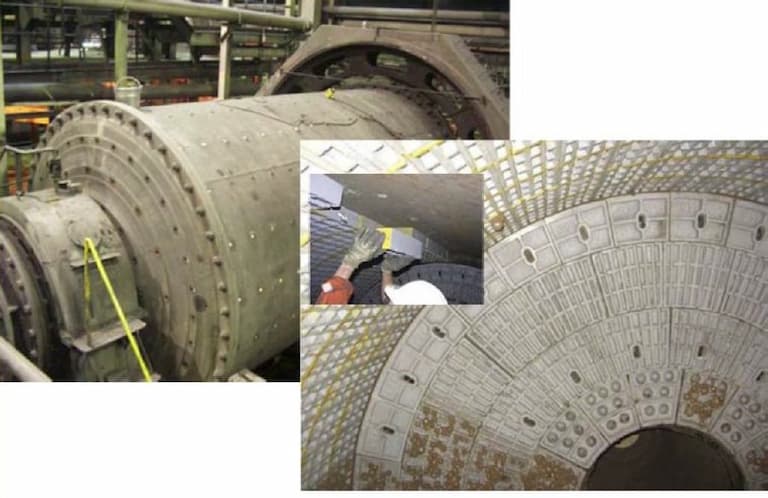

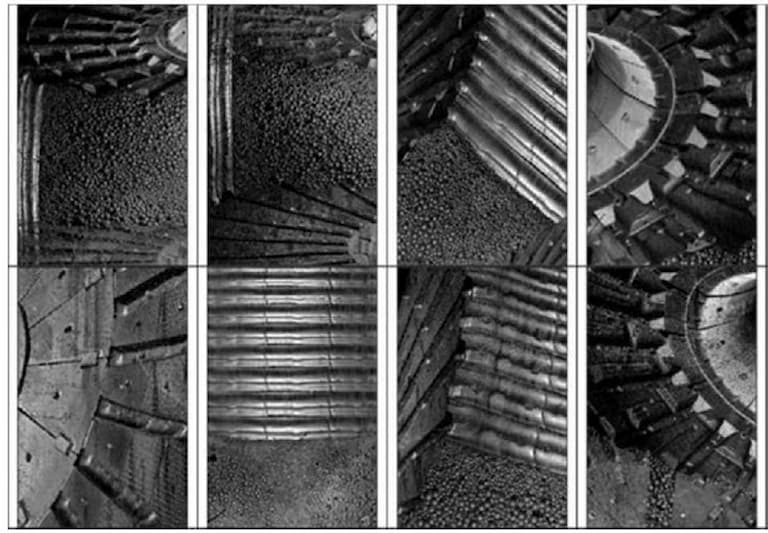

In response to the question what is a ball mill it should be said, A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. The cylindrical shell is partially filled with balls (usually made of metal like steel or ceramic) or other media (such as ceramic pebbles or stainless steel balls). As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell.In response to the question what is a ball mill machine it should be said, The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.Ball mills are used extensively in the mechanical alloying process in which they are not only used for grinding but for cold welding as well, with the purpose of producing alloys from powders. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and non-ferrous metals.

Types of ball mills

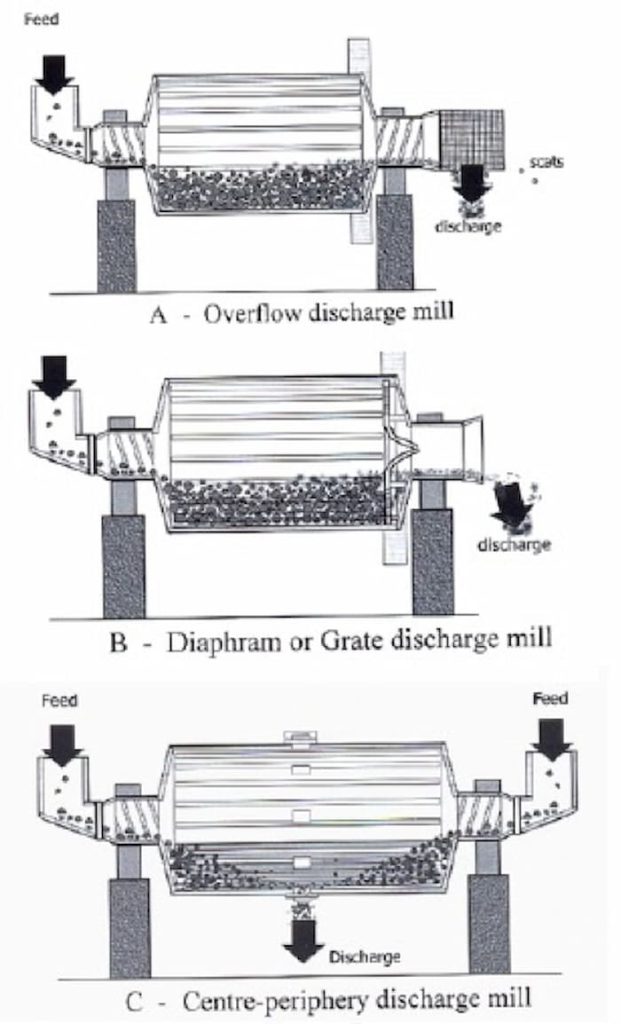

In response to the question what is the ball mill it should be said, A ball mill machine is a type of grinding mill and is key equipment for grinding materials, widely used in powder-making production line such as cement, silicate sand, new-type building material, refractory material, fertilizer, ore dressing of ferrous metal and non-ferrous metal, glass ceramics, etc. Ball mills have two ways of grinding: the dry way and the wet way. It can be divided into tabular type and flowing type according to different extracting way of mine.In the industrial field, ball mills are used extensively for mining and cement milling applications due to their high application ratio. The internal grinding media in ball mills are mostly spherical with different specifications and materials, hence the name “ball mill machine”.As a professional manufacturer and supplier of ball mill machines, In response to the question what is the ball mill it should be said, we offer various types to meet customer requirements:1. According to production mode: dry ball mill (without adding water) and wet ball mill.

2. According to the process used: dryer mill, superfine ball mill, open-circuit mill, closed-circuit grinding mill, etc.

3. According to raw materials: raw mill, cement ball mill, coal ball mill, steel slag ball mill, slag ball mill, quartz ball mill, aluminum ash ball mill, etc.

The ball mill machine consists mainly of a cylindrical cylinder, end cover, bearing, and big gear ring. The cylinder is filled with grinding media (steel balls or steel cylpebs) with a diameter of 25mm-150mm, occupying 25%-50% of the effective volume of the cylinder. The end covers facilitate feeding and discharging, connected with the cylinder body by screws. Bearings support the cylinder’s rotation.The ball mill working process occurs in the cylinder: as the cylinder rotates, the grinding media falls due to its own weight, impacting and grinding the raw materials. Meanwhile, the revolution and rotation of the grinding media generate extrusion and peeling forces, effectively grinding the materials.These ball mill machines are crucial in various industrial applications due to their efficiency and versatility in grinding materials into fine powders or slurries.

Application of ball mill

In response to the question what is a ball mill it should be said, In the field of extractive metallurgy and mineral processing, the ball mill plays a crucial role in comminution processes. Comminution refers to the process of size reduction of bulk materials such as minerals and ores. The ball mill is specifically designed for this purpose, employing grinding media (steel balls or ceramic balls) to achieve the desired particle size reduction through impact and attrition forces.

Comminution Processes:

1. Crushing: This is the initial stage where large rocks or ore particles are subjected to mechanical forces to reduce their size. Jaw crushers, gyratory crushers, and cone crushers are commonly used in crushing operations.

2. Grinding: Following crushing, grinding further reduces the particle size of the material. Grinding is typically performed using ball mills and rod mills, where the grinding media (balls or rods) cascade within the mill to crush and grind the material. Grinding is usually carried out wet, enhancing efficiency and reducing wear on the grinding media.

Application of Ball Mill

- Primary Comminution Tool: Ball mills are primary devices used for grinding or comminution in mineral processing plants. They are pivotal equipment for grinding crushed materials and are widely utilized in various stages of comminution circuits.

- Types of Mills: Ball mills can operate in open or closed circuit for wet or dry grinding. They are versatile machines capable of handling a wide range of materials and tailored for different operational conditions.

- Industrial Applications: Ball mills find extensive applications in mining, cement plants, power generation, and other industrial sectors where comminution of materials is required. They are indispensable for achieving the desired particle size distribution and ensuring optimal performance of downstream processes.

- In summary, the ball mill serves as a fundamental tool in mineral processing and extractive metallurgy by facilitating effective comminution of ores and minerals. Its application extends across various stages of material processing, ensuring economic viability through efficient particle size reduction and high recovery rates of valuable minerals.

Important points of working with a ball mill

In response to the question what is a ball mill it should be said, Operating a ball mill involves several key steps to ensure efficient processing of materials:

1. Preparation: Before starting, ensure the ball mill is properly set up with the correct grinding media and materials.

2. Loading: Fill the mill with the appropriate grinding media (such as steel balls or ceramic balls) and the material to be ground. This ensures proper grinding action inside the mill.

3. Feeding: Use a suitable feed system to introduce the material into the mill. The feed should be steady and controlled to maintain optimal operation.

4. Starting the Mill: Initiate the mill’s operation by starting the rotation. Depending on the design, this may involve starting a motor or engaging a gearbox to drive the mill’s rotation.

5. Adjustments: Monitor the mill’s performance closely and make adjustments as necessary. This includes adjusting the speed of rotation, the direction of rotation (if applicable), and other operational parameters to achieve the desired output.

6. Optimization: Continuously optimize the operation based on the material being processed and the desired product specifications. This may involve fine-tuning the grinding media size, mill speed, and feed rate to maximize efficiency and product quality.

Overall, operating a ball mill effectively requires attention to detail and understanding of the mill’s capabilities and limitations. By following these steps and maintaining regular maintenance, you can ensure reliable and efficient operation of your ball mill in various industrial applications.

Advantages of ball mill machine

- Versatility and High Capacity:

Ball mills are widely used due to their versatility in grinding materials and high capacity, making them suitable for a wide range of applications in various industries. - Consistent Milling Fineness:

They can maintain a prescribed milling fineness over long periods by periodically adding balls to compensate for wear, ensuring consistent performance. - Reliability and Safety:

Ball mills are known for their reliability and safety features, along with ease of maintenance, which contributes to their widespread use in industrial settings.

Conclusion

In conclusion, ball mills play a crucial role in various industrial processes, offering versatility, high capacity, and reliability. Their ability to grind materials effectively and maintain consistent milling fineness makes them indispensable in mineral processing, metallurgy, building materials, and chemical industries.

FAQ

A ball mill is used for grinding and blending materials in various industries and applications. It works on the principle of impact and attrition, where size reduction is achieved by the impact of the balls dropping down from the top of the mill’s shell. Ball mills are commonly used to grind and mix materials for use in industries such as construction, mining, ceramics, and pharmaceuticals.

The advantages include versatility, high capacity, long-term milling fineness retention, reliability, safety, and ease of maintenance.

Drawbacks may include bulkiness, high specific energy consumption due to wear of grinding media and mill walls, friction, and material heating during operation.

Ball mills are commonly used in mineral processing, building materials, metallurgy, and chemical industries for grinding, mixing, and blending of materials.