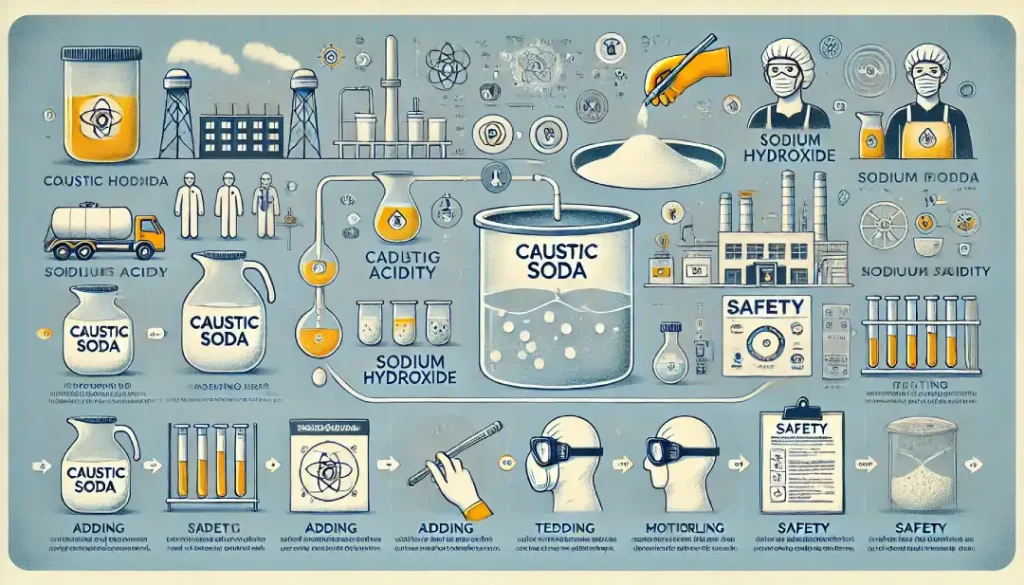

Caustic soda, also known as sodium hydroxide (NaOH), is a highly versatile and essential chemical widely used across various industries. It comes in different forms, including solid (flakes and pellets) and liquid, each with specific applications. The technical grades of caustic soda refer to its classification based on purity levels, as well as the types of impurities and heavy metals present in the compound. These grades are particularly important for industries that require precise chemical properties for specific applications. For instance, caustic soda used in food processing, water treatment, or chemical manufacturing will have different purity standards compared to the industrial-grade variety used in soap production or petroleum refining. In this article, we will delve into the different technical grades of caustic soda, explaining their properties, uses, and the standards that govern their quality.

Technical Grades of Caustic Soda

Caustic soda (NaOH), commonly known as lye or caustic, is a strong alkaline substance that is essential for various industrial processes. The technical grades of caustic soda are determined by its purity level and the presence of impurities such as heavy metals and other contaminants. These grades are essential for ensuring the desired performance of caustic soda in different applications, from chemical manufacturing to food production and water treatment. The different grades of caustic soda are tailored to meet specific industry standards, and understanding these grades is crucial for selecting the right type for each application.

Industrial Grade Caustic Soda

The industrial grade of caustic soda is the most commonly used form of this chemical. It is typically available in solid form, such as flakes or pellets, and in concentrated liquid solutions. This grade of caustic soda is often used in large-scale chemical production, paper manufacturing, and petroleum refining. Industrial-grade caustic soda is known for its high purity, with an NaOH concentration typically ranging from 96% to 98%. However, it may contain small amounts of impurities such as sodium chloride, sodium carbonate, and sodium sulfate.

The main use of industrial-grade caustic soda is in the production of soap, detergents, and various chemicals. It is also used to neutralize acids in wastewater treatment plants, as well as in petroleum refining to remove impurities from crude oil. While industrial-grade caustic soda is highly effective for most chemical processes, the level of purity required may not be suitable for certain food or pharmaceutical applications, which is where higher purity grades come into play.

Technical Grade Caustic Soda for Food Processing

One of the critical applications of caustic soda is in the food industry, where it is used for food processing, including the production of food additives, and for cleaning equipment in food processing plants. The technical grades of caustic soda for food applications must meet stringent purity requirements to ensure that it does not introduce harmful impurities into food products.

Caustic soda used in food processing should comply with food-grade standards, with a purity level typically exceeding 99%. This grade is subject to strict regulations, such as the ones set by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). It must be free from harmful substances like heavy metals, including arsenic, mercury, and lead, which can pose serious health risks if they contaminate food.

In the food industry, caustic soda is used for tasks like peeling fruits and vegetables, processing cocoa beans, and producing corn syrup. It is also utilized for cleaning and sanitizing equipment in food processing facilities. The high purity of food-grade caustic soda ensures that it meets safety standards while maintaining its effectiveness in these applications.

Pharmaceutical Grade Caustic Soda

Pharmaceutical-grade caustic soda is another specialized form of sodium hydroxide that is used in the production of pharmaceuticals, personal care products, and other health-related applications. This grade must meet even stricter purity standards than food-grade caustic soda, as the presence of contaminants can have serious implications for human health.

Pharmaceutical-grade caustic soda must typically have a purity level of 99.5% or higher. It is used in the synthesis of various active pharmaceutical ingredients (APIs) and in the manufacture of medical devices and personal care products like soaps and cosmetics. The high level of purity in pharmaceutical-grade caustic soda helps ensure that no harmful residues or byproducts are introduced during the manufacturing process.

Caustic Soda for Water Treatment

In water treatment, caustic soda is commonly used for pH adjustment, coagulation, and flocculation. The technical grades of caustic soda for water treatment must meet specific quality standards to ensure that the chemical is effective in neutralizing acids and treating wastewater. Water treatment-grade caustic soda typically contains 98% or higher purity levels.

In addition to its use in municipal water treatment plants, caustic soda is also employed in the treatment of industrial effluents and in the production of drinking water. Caustic soda helps remove heavy metals, neutralize acidic pollutants, and regulate the pH of water to make it safe for consumption or discharge.

Special Grades for Specific Applications

There are also various special grades of caustic soda that are designed for specific industrial applications. These include grades that are formulated to be free from certain impurities, such as heavy metals, chlorine, or sulfur. Special-grade caustic soda may be required for applications where even trace amounts of contaminants can compromise product quality or safety.

For example, in the production of biodiesel, caustic soda with specific impurities removed may be required to ensure that the biodiesel produced meets quality standards. Similarly, in the production of high-quality detergents and cleaning products, a special-grade caustic soda may be used to achieve superior performance without introducing undesirable substances.

The Importance of Technical Grades in Manufacturing

The technical grades of caustic soda play a crucial role in ensuring the success of chemical processes across various industries. Choosing the appropriate grade is essential for maintaining the desired chemical reactions, ensuring product safety, and meeting regulatory requirements. For instance, the presence of impurities in lower-quality caustic soda can lead to unwanted side reactions, resulting in lower yields or the formation of harmful byproducts.

To meet the stringent requirements of industries like food processing, pharmaceuticals, and water treatment, caustic soda manufacturers must ensure that their products adhere to the highest standards of purity. These standards are set by international organizations such as the American National Standards Institute (ANSI), the European Union (EU), and the International Organization for Standardization (ISO). Manufacturers must also comply with regional regulations, such as those enforced by the U.S. Environmental Protection Agency (EPA) or the Food Safety and Standards Authority of India (FSSAI).

Conclusion

The technical grades of caustic soda are essential for ensuring that this highly versatile chemical is used effectively and safely across various industries. From industrial and food processing applications to pharmaceutical production and water treatment, each grade of caustic soda is tailored to meet specific purity standards and regulatory requirements. By selecting the appropriate technical grade, industries can achieve optimal performance, ensure product quality, and comply with safety standards. Understanding the technical grades of caustic soda is vital for anyone involved in the procurement, production, or use of this chemical in industrial or commercial applications.

For more information about caustic soda and its applications, you can visit the Alpha Grinding Media website.

Frequently Asked Questions

What is the difference between technical grades of caustic soda?

Technical grades of caustic soda differ based on their purity and intended use. For instance, food-grade caustic soda has higher purity levels, whereas industrial-grade caustic soda may contain higher levels of impurities suitable for non-food applications.

What are the typical applications of technical grades of caustic soda?

Technical grades of caustic soda are used in various industries, including chemical manufacturing, paper production, water treatment, and food processing, depending on the purity and form (solid or liquid).

How do I know if a specific caustic soda is suitable for my industry?

You should refer to the specifications and quality standards that correspond to your industry. For example, in the pharmaceutical or food industry, a higher purity technical grade of caustic soda is required, whereas industrial applications may allow for lower-grade versions.

Can technical grades of caustic soda be harmful if not handled properly?

Yes, caustic soda is highly corrosive, and improper handling can lead to severe burns or other health hazards. It is crucial to follow safety guidelines when handling and using technical grades of caustic soda.