Steel grinding balls are fundamental to various industrial processes, serving as critical media for size reduction and material processing in ball mills. These spherical grinding media are engineered to endure extreme mechanical stresses, providing efficient size reduction of ores and raw materials while maintaining long service life and consistent performance. Their operation relies on the principle of impact and attrition, where the movement of the mill, along with the interaction, collisions, and attrition between the grinding balls and the material, reduces the material to the desired size. The selection and quality of grinding balls directly influence operational efficiency, production costs, and equipment longevity, making them a critical factor in industrial process optimization.

Diverse Types and Materials of Steel Grinding Balls

Manufacturers offer a wide array of steel grinding balls, each tailored for specific applications and performance requirements:

1. Stainless Steel Balls

These are highly versatile. 304 stainless steel balls are the most widely used, known for being a typical representative of austenitic stainless steel. They are generally non-magnetic, possess good rust resistance and certain corrosion resistance, are moderately priced, widely used, and offer high cost performance. Condar, a professional steel ball supplier, produces 304, 316, 420C, and 440C stainless steel balls. Stainless steel balls are noted for their outstanding corrosion resistance, making them suitable for applications requiring a high degree of purity and hygiene, such as in the food and medical fields where safety is paramount.

2. Carbon Steel Balls

These include Soft Carbon Steel Ball and Hardened Carbon Steel Ball variants. Fox Industries offers Carbon Steel Balls known for their hardness and cost-effectiveness, making them a practical choice for many ball mill processes. They also provide Carbon Forged Steel Balls, which deliver exceptional strength and impact resistance, ideal for heavy-duty ball milling.

3. Bearing Steel Balls

Condar manufactures both Precision and Grinding Bearing Steel Balls, designed for applications requiring high precision and durability.

4. Chrome Steel Balls

Fox Industries produces Chrome Steel Balls that offer excellent wear resistance and precision, making them perfect for high-precision ball milling tasks.

5.High Carbon and Forged Grinding Balls

Molycop designs its grinding balls for maximum abrasion resistance by utilizing high carbon content and high hardness levels for outstanding performance. They manufacture forged grinding balls in nominal sizes from 1.0” to 4.0” in diameter for ball milling and regrind applications.

6. High/Low Chromium Steel

SMAT Mine manufactures grinding balls using premium-grade high/low chromium steel, in addition to forged steel and ceramic materials, ensuring durability and performance in demanding environments.

Key Characteristics and Performance Attributes

The effectiveness of steel grinding balls is determined by several critical characteristics:

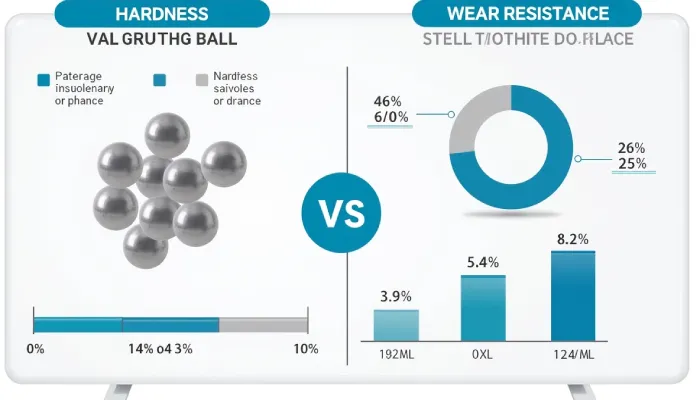

1. Hardness and Wear Resistance

Grinding balls are designed for high hardness and wear resistance. Molycop controls surface and cross-sectional hardness through carefully selected heat treatment variables and specific alloy additions. SMAT Mine emphasizes rigorous quality control to ensure consistent hardness, wear resistance, and impact toughness. Fox Industries’ steel balls are engineered for superior durability and performance.

2. Chemistry and Microstructure

The chemical profile of grinding balls is developed to correspond with heat treatment requirements, with specific alloy additions included to produce optimum physical properties. Advanced heat treatment technology and precision alloy composition extend the service life of grinding balls, lowering the total cost per ton of ground material.

3. Corrosion and Rust Resistance

Stainless steel balls, particularly 304 stainless steel, offer good rust resistance and certain corrosion resistance. Fox Industries highlights the outstanding corrosion resistance of stainless steel balls for applications requiring purity and hygiene.

4. Customization and Quality Control

Many manufacturers offer customization in size and material grade to meet specific needs. Companies like SMAT Mine adhere to certifications such as ISO 9001, SGS, and ASTM/EN standards to ensure unmatched product quality. Marteau Lemarie produces steel and stainless steel balls in grade 1000 with perfectly polished, smooth, and shining surfaces.

Applications Across Various Industries

Steel grinding balls are indispensable in a wide range of industrial applications, significantly impacting productivity and cost-effectiveness across multiple sectors.

Mining: Gold, Copper, and Iron Ore Processing

The mining industry heavily relies on steel grinding balls for ore processing. In gold mining, the comminution stage involves crushing and grinding gold-bearing rocks into fine particles to facilitate efficient liberation of gold for extraction through leaching or flotation. High-quality forged grinding balls reduce media consumption and downtime, improving throughput and gold recovery rates in downstream hydrometallurgical processes.

In copper mining, one of the largest consumers of grinding balls, forged steel balls are preferred for their exceptional wear resistance, impact strength, and fatigue life. These properties ensure reliable performance in SAG and ball mills, reducing mill downtime, lowering replacement rates, and enhancing copper yield, which contributes to cost savings and environmental sustainability.

In iron ore processing, forged grinding balls are integral to rod and ball mills, providing consistent size reduction. Their mechanical strength and wear resistance facilitate extended service life, improving pelletizing efficiency and final pellet quality for blast furnace and direct reduction iron (DRI) operations.

Cement Industry

In cement plants, raw materials such as limestone, clay, and additives require fine grinding prior to kiln processing. Ball mills charged with forged grinding balls ensure efficient material size reduction, leading to improved kiln feed consistency and clinker quality. The durability and hardness of forged grinding balls reduce media consumption and downtime, enhancing overall plant productivity.

Thermal Power Plants

In coal-fired thermal power plants, grinding balls are essential for pulverizing coal into a fine powder in ball mills or vertical roller mills. The efficiency of coal pulverization affects boiler combustion efficiency, heat rate, and emission control. High-quality forged grinding balls minimize wear on mill liners and grinding chambers, ensuring stable operation and reduced maintenance costs.

Pigments, Paints, Cosmetics, and Food

Magotteaux’s grinding balls are used to grind materials for these industries, where precision and purity are critical. Stainless steel balls, particularly 304 stainless steel, are suitable due to their safety and non-toxic properties.

Advantages of Forged Grinding Balls Over Cast Alternatives

Forged grinding balls offer significant performance advantages that translate into operational benefits:

- Superior Mechanical Properties: Forged balls exhibit higher density and improved internal structure, providing better impact toughness and wear resistance.

- Extended Service Life: Their enhanced durability reduces the frequency of replacements, lowering procurement and downtime costs.

- Consistent Quality: The forging process ensures uniform hardness and mechanical characteristics, critical for predictable mill performance.

- Reduced Operational Risks: Forged grinding balls are less prone to fragmentation, minimizing mill liner damage and contamination of processed material.

These benefits make forged grinding balls the preferred choice in demanding industrial milling applications.

Leading Manufacturers and Suppliers

Several expert manufacturers contribute to the global supply of high-quality steel grinding balls:

- Condar: A professional steel ball supplier based in China, known for producing stainless steel balls of various specifications, including 304 Stainless Steel Ball. They offer rich production experience and timely delivery.

- Molycop: Specializes in grinding balls designed for maximum abrasion resistance, manufactured to exacting internal specifications at their global facilities. They supply forged, cast high-chrome, or ceramic grinding media.

- SMAT Mine: A leading global manufacturer with 20 years of expertise, specializing in high-performance grinding balls for ball mill applications, with a focus on durability and cost-effectiveness. They provide comprehensive after-sales support.

- Magotteaux: Offers grinding balls made from a large range of alloys, specially adapted to the material to be ground, mill operating parameters, and wear mechanisms, aiming for the lowest wear and far greater efficiency.

- Fox Industries: Provides superior industrial milling and grinding media, including a wide range of steel balls, since 1989. Their focus on research and development aims to change the world through ultra-fine particle size reduction.

- Marteau Lemarie: Offers steel and stainless steel balls for grinding and polishing, generally available from stock in standard diameters and tolerances.

- ALPHA Grinding Media: Specializes in manufacturing premium forged grinding balls designed for maximum wear resistance, optimal hardness, and consistent toughness. They provide customized solutions tailored to unique operational challenges, ensuring enhanced equipment longevity and return on investment.

Conclusion: Strategic Importance of Steel Grinding Balls

Steel grinding balls—particularly forged varieties—are fundamental to the efficiency, cost-effectiveness, and reliability of numerous industrial processes. From gold, copper, and iron ore mining to cement production and thermal power generation, the quality of grinding media influences both operational performance and economic outcomes. As industries face increasing pressure to improve productivity, reduce costs, and minimize environmental impact, investing in high-performance forged grinding balls is a strategic decision that supports sustainable industrial growth.

For inquiries or to learn more about optimizing milling processes, contact expert suppliers like ALPHA Grinding Media for tailored grinding media solutions.