In the mining industry, grinding mills are vital for breaking down ores into finer particles to extract valuable minerals. Two predominant types, SAG mills and ball mills, play critical roles in this process, yet their operational mechanisms and applications differ significantly. Understanding the Difference between SAG mills and ball mills is essential for optimizing grinding circuits and selecting appropriate mining grinding media. At Alpha Grinding Media, we provide forged steel grinding balls designed to enhance performance in both mill types.

SAG mills, or Semi-Autogenous Grinding mills, use ore and a small amount of grinding balls for mining to crush materials, ideal for primary grinding. Conversely, ball mills rely heavily on high-performance grinding balls for finer, secondary grinding. This distinction impacts efficiency, energy use, and media requirements. Choosing the right mill and mining grinding media can significantly affect operational costs and output quality. Our expertise ensures that our forged steel grinding balls meet the unique demands of both systems.

This blog delves into the Difference between SAG mills and ball mills, exploring their mechanics, applications, and how Alpha Grinding Media’s high-performance grinding balls optimize performance. By understanding these differences, mining operators can make informed decisions to enhance productivity and reduce costs, leveraging our tailored grinding balls for mining to achieve superior results.

What Are SAG Mills?

SAG mills are large rotating drums used for primary grinding in mining. They rely on ore and a small volume of forged steel grinding balls for semi-autogenous grinding. The Difference between SAG mills and ball mills lies in their grinding approach, with SAG mills using ore as the primary grinding medium. They are ideal for processing hard ores like gold and copper.

Key Features of SAG Mills

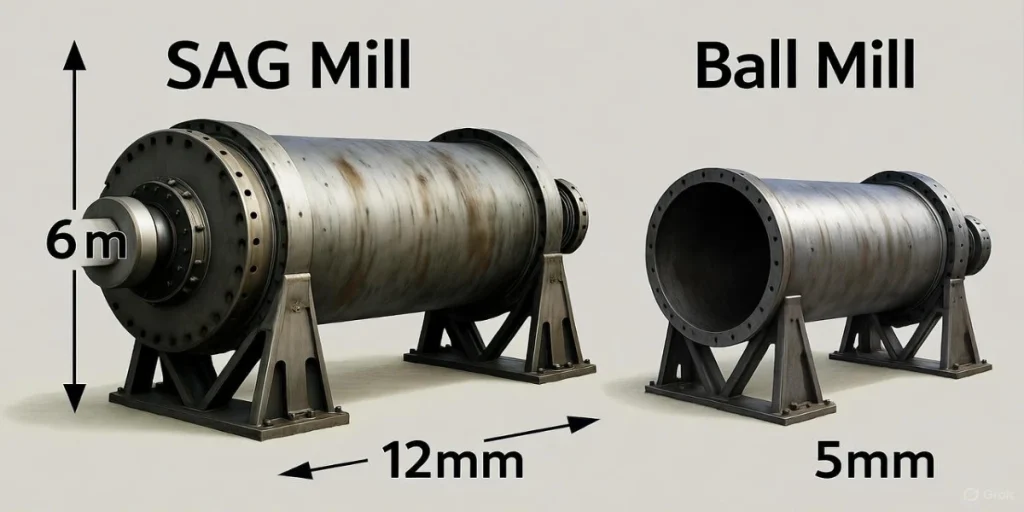

- Large Size: SAG mills have diameters up to 40 feet, handling high-throughput operations.

- Ore-Driven Grinding: Ore acts as the main grinding agent, reducing reliance on grinding balls for mining.

- Energy Intensive: They consume significant energy for coarse grinding tasks.

- Versatility: SAG mills process various ore types, making them suitable for large-scale mining.

This makes the Difference between SAG mills and ball mills critical for primary grinding strategies.

What Are Ball Mills?

Ball mills are cylindrical devices used for secondary or tertiary grinding. They rely on a high volume of high-performance grinding balls to grind materials through impact and abrasion. The Difference between SAG mills and ball mills is evident in their media dependency, as ball mills require robust mining grinding media. They produce finer particle sizes for further processing.

Key Features of Ball Mills

- Smaller Size: Ball mills typically have diameters of 10–20 feet.

- Media Dependency: They rely entirely on forged steel grinding balls for grinding.

- Finer Grinding: Ball mills excel at producing uniform, fine particles.

- Energy Efficiency: They are efficient for fine grinding tasks.

The Difference between SAG mills and ball mills highlights their distinct roles in grinding circuits.

Comparing Grinding Mechanisms

The Difference between SAG mills and ball mills centers on their grinding mechanisms. SAG mills use a combination of ore and grinding balls for mining for semi-autogenous grinding. This reduces the need for extensive mining grinding media. In contrast, ball mills depend solely on high-performance grinding balls for impact and abrasion. This distinction affects their efficiency and media requirements.

Grinding Stage Applications

Another Difference between SAG mills and ball mills is their application in grinding stages. SAG mills are used for primary grinding, breaking large ore pieces into smaller sizes. Ball mills are employed for secondary or tertiary grinding, refining particles for processes like flotation. This sequential use optimizes the grinding circuit, leveraging the Difference between SAG mills and ball mills.

Media Requirements

The Difference between SAG mills and ball mills significantly impacts media needs. SAG mills require fewer forged steel grinding balls, as ore contributes to grinding. Ball mills, however, need a higher volume of mining grinding media to achieve fine grinding. The quality of high-performance grinding balls is crucial for ball mills to maintain efficiency.

Throughput and Size Considerations

Throughput highlights another Difference between SAG mills and ball mills. SAG mills handle larger ore sizes and higher throughput, suitable for large-scale operations. Ball mills process smaller ore sizes with lower throughput, focusing on precision. This Difference between SAG mills and ball mills influences mill selection based on operational scale.

Energy Consumption

Energy use is a key Difference between SAG mills and ball mills. SAG mills consume more energy due to their size and coarse grinding tasks. Ball mills are more energy-efficient for finer grinding, optimizing energy use for specific particle sizes. This Difference between SAG mills and ball mills affects operational costs significantly.

Why Forged Steel Grinding Balls Are Essential

The Difference between SAG mills and ball mills underscores the importance of quality mining grinding media. Alpha Grinding Media’s forged steel grinding balls are designed for both mill types, offering:

- High Hardness: 55–65 HRC for durability in SAG mills and ball mills.

- Wear Resistance: Reduces replacement frequency for grinding balls for mining.

- Custom Sizes: 20–150mm, tailored for specific mill requirements.

- Uniform Structure: Ensures reliable performance in mining grinding media applications.

Our high-performance grinding balls enhance efficiency across both systems, addressing the Difference between SAG mills and ball mills.

Operational Efficiency and Cost

The Difference between SAG mills and ball mills impacts operational efficiency. SAG mills reduce costs by using ore as a grinding medium, minimizing grinding balls for mining needs. Ball mills require more forged steel grinding balls, increasing media costs but ensuring finer output. Alpha Grinding Media’s high-performance grinding balls optimize costs for both.

Maintenance and Downtime

Maintenance is another Difference between SAG mills and ball mills. SAG mills have complex maintenance due to their size and ore variability. Ball mills are easier to maintain, with predictable wear patterns of mining grinding media. Our forged steel grinding balls reduce downtime by offering superior durability.

Material Suitability

The Difference between SAG mills and ball mills affects material suitability. SAG mills handle hard, coarse ores like copper or gold effectively. Ball mills are better for softer materials requiring fine grinding. Choosing the right mill and high-performance grinding balls ensures optimal material processing.

Integration in Grinding Circuits

Many operations combine SAG mills and ball mills to leverage the Difference between SAG mills and ball mills. SAG mills perform primary grinding, while ball mills refine the output. Alpha Grinding Media provides mining grinding media tailored for this integrated approach, enhancing overall efficiency.

Choosing the Right Mill

Selecting between SAG mills and ball mills depends on the Difference between SAG mills and ball mills and your operational needs. Use SAG mills for high-throughput, coarse grinding of hard ores. Choose ball mills for finer, precise grinding. Alpha Grinding Media’s forged steel grinding balls support both, ensuring optimal performance.

Why Alpha Grinding Media?

Alpha Grinding Media excels in providing high-performance grinding balls for both SAG mills and ball mills. Our forged steel grinding balls offer unmatched hardness and wear resistance, addressing the Difference between SAG mills and ball mills. With steel industry expertise, we deliver customized mining grinding media solutions to enhance your grinding operations.

Conclusion

Understanding the Difference between SAG mills and ball mills is vital for optimizing mining operations. SAG mills excel in coarse, high-throughput grinding, while ball mills deliver fine, precise output. By choosing Alpha Grinding Media’s forged steel grinding balls, you can enhance efficiency and reduce costs across both systems. Our high-performance grinding balls are tailored to meet the unique demands of each mill, ensuring superior performance. Contact us to elevate your grinding circuit with our industry-leading mining grinding media.

Frequently Asked Questions

What is the main Difference between SAG mills and ball mills?

SAG mills use ore and minimal grinding balls for mining for coarse grinding, while ball mills rely on forged steel grinding balls for finer grinding.

Which mill is better for primary grinding?

SAG mills are ideal for coarse, primary grinding due to their high-throughput design.

Why are high-performance grinding balls crucial for ball mills?

Ball mills depend on mining grinding media for efficient, fine grinding, requiring durable balls.

Can Alpha Grinding Media support both mill types?

Yes, our forged steel grinding balls are optimized for both SAG mills and ball mills.