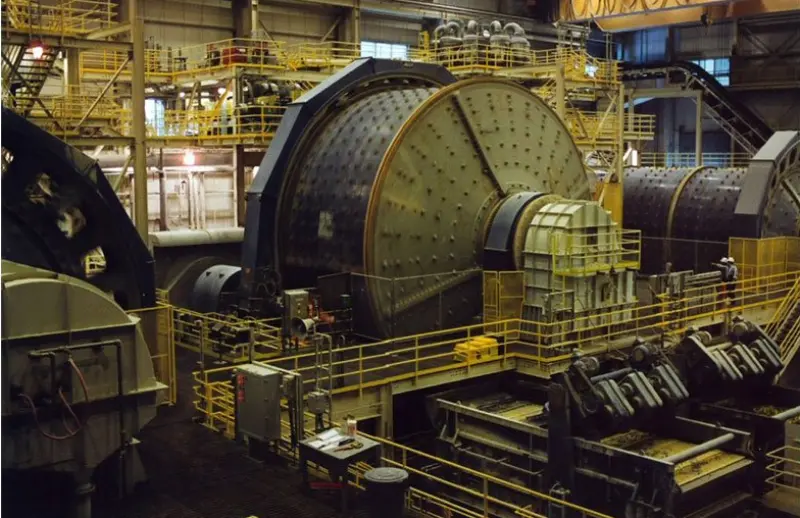

Semi-autogenous grinding (SAG) mills are powerhouse machines in the mining industry, designed to crush and grind large ore particles into finer sizes for further processing. These mills combine the power of impact and attrition to process high volumes of material, making them essential for large-scale operations like gold, copper, and iron ore mining. This guide from alpha grinding media explores what SAG mills are, how they work, types of SAG Mills and benefits in mineral processing.

What Is a SAG Mill?

A SAG mill (semi-autogenous grinding mill) is a robust grinding machine used primarily in the mining industry to reduce large ore particles (up to 250 mm) into smaller sizes (1–5 mm) suitable for downstream processes like flotation or leaching. Unlike traditional ball mills, which rely solely on steel or ceramic balls, SAG mills use a combination of the ore itself and supplemental grinding media, typically steel balls, to achieve efficient grinding. This hybrid approach reduces the need for excessive media, making SAG mills cost-effective for large-scale operations.

The key to how do SAG mills work lies in their ability to leverage the ore as part of the grinding medium, minimizing costs while maximizing throughput. Alpha Grinding Media’s premium steel balls are engineered to complement this process, offering exceptional wear resistance and impact strength for consistent performance.

Key Components of a SAG Mill

To understand how do SAG mills work, it’s essential to know their core components, each playing a vital role in the grinding process:

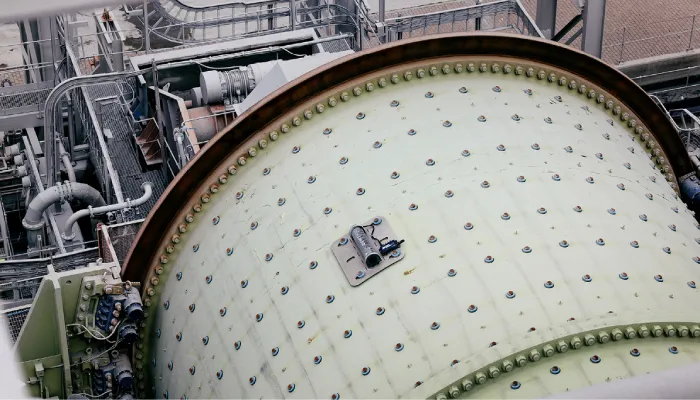

- Rotating Drum: The heart of the SAG mill, this large cylindrical rotates to create the tumbling action that drives grinding. Its robust design handles thousands of tons of ore daily.

- Grinding Media: Steel balls, usually 100–150 mm in diameter, supplement the ore’s grinding action. Alpha Grinding Media provides high-quality balls optimized for SAG mills, ensuring durability and efficiency.

- Liners: Wear-resistant rubber or steel linings protect the drum’s interior and optimize material flow, extending the mill’s lifespan.

- Motor and Drive System: High-power motors (up to 20 MW) drive the drum at 10–15 RPM, ensuring efficient grinding without overloading.

- Discharge System: Grates or trommels allow finer particles to exit while retaining larger ones for further grinding, maintaining consistent output.

These components work in harmony to make SAG mills a reliable solution for mineral processing.

Types of SAG Mills

SAG mills come in various configurations to suit different grinding needs, each impacting how do SAG mills work:

- High-Aspect SAG Mills: With a larger diameter-to-length ratio these mills maximize throughput for large mines processing high volumes of ore.

- Low-Aspect SAG Mills: Longer drums with a smaller diameter-to-length ratio provide finer grinding, ideal for precise particle size control.

- Single-Stage SAG Mills: Used standalone in smaller operations, these mills handle primary grinding, reducing equipment costs.

- SAG-Ball Mill Circuits: Paired with ball mills for secondary grinding, these circuits are common in large-scale plants for complex ores.

While primarily used in mining, SAG mills are adaptable for coarse grinding in industries like cement or aggregate processing.

How SAG Mills Work

The operating principle of a SAG mill involves a rotating drum that causes the ore and grinding media to tumble, creating a combination of impact and attrition forces to break down the material.

- Impact Grinding: Large ore particles and steel balls collide as the drum rotates, crushing the ore into smaller fragments.

- Attrition Grinding: Smaller particles are further reduced through friction as they rub against each other and the media.

- Critical Speed: SAG mills operate at 70–80% of critical speed (Nc = 42.3/√D, where D is the drum diameter in meters), typically 10–15 RPM for a 12-meter mill.

- Feed and Discharge: Ore is fed into the mill continuously, and finer particles exit through grates or trommels, while larger particles remain for further grinding.

For example, in a copper mine, a SAG mill might process 50,000 tons of ore per day, reducing particle sizes from 150 mm to 1–5 mm for downstream processing.

Benefits of SAG Mills

SAG mills offer several advantages that make them a preferred choice for large-scale grinding:

- High Throughput: Capable of processing thousands of tons of ore per hour, ideal for large mining operations.

Reduced Media - Consumption: Using ore as part of the grinding medium lowers the need for steel balls, reducing costs.

Energy Efficiency: Optimized designs and large-scale operation minimize energy use per ton of material processed. - Flexibility: Can handle a wide range of ore types, from soft gold ores to hard iron ores.

- Low Maintenance: Durable liners and robust designs reduce downtime and maintenance costs.

These benefits make SAG mills a cost-effective and efficient solution for mineral processing.

Conclusion

Understanding how do SAG mills work is key to unlocking their potential in mineral processing. By combining impact and attrition grinding, SAG mills efficiently reduce large ore particles, making them essential for gold, copper, and iron ore mining. With high throughput, energy efficiency, and versatility, SAG mills, paired with Alpha Grinding Media’s premium steel balls, deliver consistent, cost-effective results. By addressing common challenges and optimizing operations, you can achieve finer particle sizes and higher productivity.

Ready to elevate your SAG mill performance? Contact Alpha Grinding Media for a free consultation or sample of our high-quality grinding media tailored to your needs. Visit our website to learn more and start optimizing your grinding process today.

Frequently Asked Questions

1. What is the difference between a SAG mill and a ball mill?

A SAG mill uses a combination of ore and steel balls as grinding media, making it ideal for coarse grinding in large-scale mining operations. A ball mill relies entirely on steel or ceramic balls and is typically used for finer grinding in secondary stages or smaller plants.

2. What types of ores are best processed by SAG mills?

SAG mills are ideal for hard and abrasive ores like gold, copper, iron, and nickel. They excel at processing large ore particles (up to 250 mm) into smaller sizes (1–5 mm) for further processing like flotation or leaching.

3. How can I reduce energy consumption in a SAG mill?

To reduce energy use, operate at 70–80% of critical speed, maintain a balanced media charge (10–15% of mill volume), use high-quality grinding media, and implement automated control systems to optimize feed rate and power draw.

4. How often should I replace the liners in a SAG mill?

Liner replacement depends on ore abrasiveness and mill usage. For abrasive ores like iron, replace steel liners every 6–12 months; for less abrasive ores like gold, rubber liners may last 1–2 years. Regular inspections are essential to determine replacement timing.