The process of comminution, or particle size reduction, forms the energetic backbone of countless industries, from mining and cement production to pharmaceuticals and fine chemicals. Achieving the desired particle size—the fineness required for subsequent separation, reaction, or application—is directly dependent on the efficiency of the milling circuit. At the heart of this circuit, acting as the primary agents of energy transfer, lies the grinding media.

The role of grinding media extends far beyond simple physical presence within a mill. They are the critical factor that dictates not only the final product quality and throughput but also the overall energy consumption, which can account for up to 70% of a mine’s total power use. An improper selection or management of these media can lead to soaring operational costs and substandard results.

Introduction: The Foundation of Comminution

The fundamental purpose of comminution is to liberate valuable minerals from ore or to prepare raw materials for industrial processes. This mechanical process is inherently energy-intensive and is achieved primarily through mills and pulverizers.

Defining Comminution: Purpose and Importance in Industry

Comminution encompasses crushing and grinding, processes designed to fracture material. In the grinding stage—typically carried out in ball mills or similar tumbling mills—the objective is to achieve a fine particle size distribution (PSD). This fineness is crucial for subsequent operations like flotation, leaching, or homogenization.

The Core Components of the Milling Process

Any milling circuit relies on the synergy of three main elements:

- Mills (Machinery): The vessel (e.g., ball mill, rod mill, SAG mill) that rotates and provides the kinetic energy.

- Feed Material: The ore or product being processed, defined by its hardness, abrasiveness, and size.

- Grinding Media: The sacrificial, dense bodies that absorb and transfer the mechanical energy to the feed material, initiating breakage.

Why Grinding Media Matters: More Than Just 'Balls'

High-quality grinding media are the most significant wear component in a mill. Their physical and metallurgical properties directly correlate with the mill’s efficiency. Their impact resistance, hardness, and size distribution govern the mechanism of particle breakage, making their selection a highly strategic decision that underpins operational success.

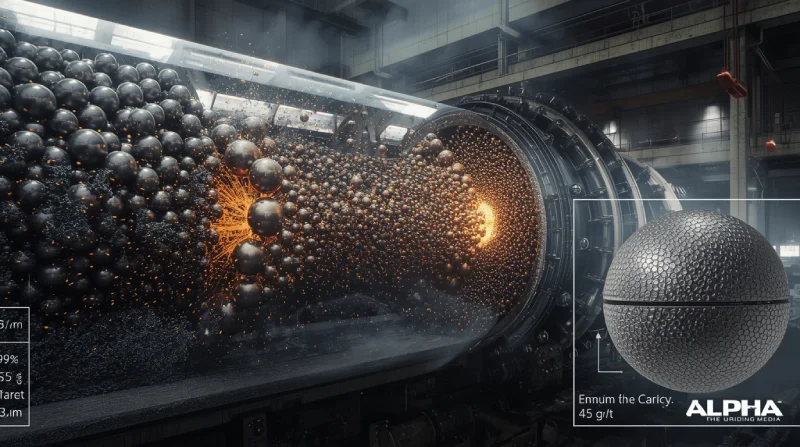

The Dual Role of Grinding Media: Impact and Attrition

The actual work of size reduction by the grinding media is executed through two distinct yet complementary mechanisms within the mill chamber.

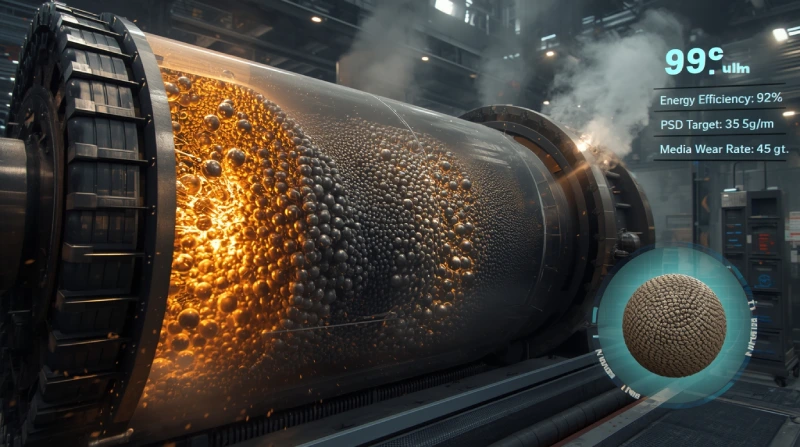

Mechanism of Action: How Media Transfers Energy

In a rotating mill, the media and charge are lifted and then fall or cascade. This movement generates the forces required for comminution:

- Impact (Crushing Large Particles): This occurs when the media are lifted high enough (cascading or cataracting action) to fall onto the charge, crushing the larger particles. Larger media, due to their greater mass and kinetic energy, excel in impact breakage.

- Attrition (Grinding Fine Particles): This is the grinding and shearing action that occurs as the media and particles slide against each other (sliding action). Smaller media provide a higher surface area and more contact points for fine grinding and powder preparation via attrition.

Maximizing Mill Throughput and Energy Efficiency

The correct selection of the media has an immediate, quantifiable effect on power consumption. The specific gravity and material integrity of the media determine how much kinetic energy is converted into useful work (particle fracture) versus wasted energy (heat, noise, and wear). The proper choice of grinding media reduces specific energy consumption (kWh/tonne).

Determining the Final Product Quality

The grinding media selection is directly tied to the end-product’s characteristics, especially in fine grinding applications.

- Influence on Particle Size Distribution (PSD): A well-optimized media charge, featuring an ideal size distribution (mixing large balls for impact and smaller balls for attrition), is essential for achieving a narrow, desired PSD.

- Preventing Contamination: In specialty applications (e.g., ceramics, pharmaceuticals), material purity is paramount. Media with lower wear rates or non-metallic materials (like ceramics) are chosen specifically to minimize contamination of the final product.

Key Characteristics of High-Performance Grinding Media

To fulfill their demanding role, media must possess a balance of physical and metallurgical properties tailored to the application. The selection process must critically evaluate these properties to ensure maximum service life and efficiency.

Key Factors Affecting Grinding Efficiency

To optimize the role of grinding media, operators must consider three critical variables:

- Surface Hardness vs. Core Hardness

A common misconception is that “harder is always better.” While surface hardness (measured in HRC) determines wear resistance, the volumetric hardness (core hardness) ensures the ball wears evenly.

If a steel ball is hard on the outside but soft inside, it will deform once the outer layer wears off, turning into an oval shape that reduces grinding efficiency. At Alpha Grinding Media, our heat treatment ensures a consistent hardness profile from surface to core. - Size Distribution (The Charge)

A mill operates best with a balanced “charge” of different ball sizes.

Large balls break coarse rocks.

Small balls increase the surface area for fine grinding.

Using only large balls results in “voids” where fine particles pass through unground. An optimized recharging recipe is crucial for maintaining throughput. - Chemical Composition

The role of alloying elements is vital:

Carbon (C): Provides hardness.

Chromium (Cr): Increases wear resistance and corrosion resistance.

Manganese (Mn): Improves toughness and hardenability.

Material Hardness and Toughness

- Hardness: Primarily dictates the media’s resistance to abrasive wear—the scraping action that causes mass loss. Harder media typically last longer, reducing the consumption rate.

- Toughness: Measures the media’s resistance to impact fracture or spalling (chipping). In high-impact environments, media must be tough enough to absorb kinetic energy without shattering, which would pollute the charge and damage the mill lining.

Size and Shape Distribution

The size of the media directly correlates with the size of the particles it can effectively fracture. Larger balls are used to break larger feed particles, while smaller balls are employed for fine grinding.

The importance of the grinding media in optimizing the process cannot be overstated. For operations demanding peak performance and reliability, Alpha Grinding Media is committed to supplying products with the precise chemical and metallurgical composition necessary to ensure excellent hardness, toughness, and maximized energy transfer.

Cost-Benefit Analysis: The Economics of Media Selection

While low-cost media might appear attractive initially, their inferior wear resistance and higher breakage rates result in significantly increased media consumption per ton of processed material. High-quality media, despite a potentially higher upfront cost, offer superior service life, reduced downtime, and better overall milling efficiency, translating into a lower total operational cost.

Types of Grinding Media and Application Considerations

The material composition of the media is selected based on the mill type, feed material characteristics, and purity requirements.

Steel Media (Forged/Cast): For Large-Scale, High-Energy Applications

Steel balls and rods remain the most common grinding media due to their high density, robustness, and cost-effectiveness in high-volume industries.

- Forged Steel: Forged Steel Known for high impact toughness, ideal for Sag and primary ball mills where impact breakage dominates.

- High-Chrome Cast Iron: Offers superior abrasion resistance, making them highly suitable for secondary ball milling of highly abrasive ores or cement clinker where the dominant mechanism is abrasion.

Ceramic Media (Alumina/Zirconia): For Fine Grinding and Low Contamination

Ceramic media are critical in applications where metal contamination must be avoided and ultrafine grinding is required.

- Alumina Balls: Offer excellent wear resistance and chemical inertness, commonly used in non-metallic minerals, paints, and pigments.

- Zirconia/Zirconium Silicate: Known for ultra-high density and exceptional hardness, these are used in high-energy stirred mills for achieving nano-scale particle sizes.

Other Materials (Pebbles, Silica, etc.)

In Autogenous (AG) and Semi-Autogenous (SAG) milling, the larger ore fragments themselves act as the grinding media. While this reduces media cost, SAG mills often require a steel ball charge (typically 6-15% of the mill volume) to assist in breaking the “critical size” particles that the ore pieces cannot effectively fracture.

Media Management for Optimal Milling Performance

Proper media management is as vital as the initial selection of the grinding media. Even the best quality media will perform poorly if the charge level or distribution is incorrect.

Understanding Media Wear and Consumption Rate

Over time, media lose mass due to abrasion, impact, and corrosion. This mass loss, or wear rate, is an important metric of media quality and operational cost. As the balls wear, their size and mass decrease, progressively reducing their energy transfer capacity.

Media Top-Up Strategy

New media must be added regularly to maintain the correct charge level and, critically, the correct size distribution. Mills require a balanced mix of larger balls (for maximum impact on fresh feed) and smaller balls (for maximum attrition on fine particles). Failing to top up with the appropriate size blend can quickly lead to inefficient grinding and ‘packing’ of the mill charge.

Impact of Slurry/Pulp Properties on Media Performance

The rheology and chemistry of the slurry or pulp (pH, viscosity, solids concentration) influence the media’s movement and corrosion rate. High pulp viscosity can impede the movement of the media, reducing the frequency of effective breakage events, while corrosive water chemistry can accelerate media degradation.

Conclusion

The role of grinding media is undeniably central to the entire comminution process. They are the essential tools that convert mechanical power into useful particle breakage, directly impacting energy efficiency, throughput, and final product quality. Effective comminution demands a data-driven approach, carefully balancing media characteristics—hardness, toughness, density, and size—against the specific requirements of the feed material and mill design. Strategic media selection, combined with rigorous inventory management, is the key to minimizing total cost of ownership and maintaining a competitive edge in today’s demanding industrial landscape.

Frequently Asked Questions

1. What is the most critical factor when selecting grinding media?

The most critical factor is the required balance between abrasion resistance (hardness) and impact resistance (toughness), which is determined by the specific mill type (e.g., ball mill vs. SAG mill) and the abrasiveness/hardness of the material being ground. Density is also critical for energy transfer.

2. How does media size affect the comminution process?

Media size determines the primary breakage mechanism. Larger media deliver a greater impact force, necessary for breaking coarse feed particles, while smaller media provide a greater total surface area for increased attrition (shearing/grinding) on finer particles. An optimal mix of sizes is often necessary for efficiency.

3. What is the difference between impact and attrition in milling?

Impact refers to the crushing action when media fall from a height onto the feed material (used for coarse particles). Attrition refers to the shearing, rubbing, or abrasion action that occurs when media slide past one another (used for fine particles and polishing).

4. How often should grinding media be added or replaced?

Grinding media should be continuously or regularly topped up rather than replaced entirely. This compensates for wear loss and maintains the optimal charge volume and size distribution necessary for consistent mill performance and efficient energy usage.