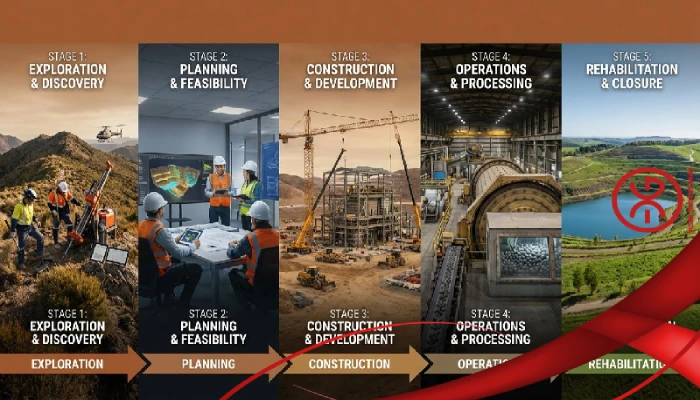

The extraction of minerals from the earth is one of the oldest and most essential industries in human history. However, for those entering the field or looking to understand the broader context of their work, it is crucial to recognize that a mine is not just a hole in the ground; it is the result of a complex, long-term lifecycle. The journey from a geologist’s initial hypothesis to the production of a refined metal involves a series of distinct phases. Understanding the stages of a mining project is essential for engineers, investors, and industry partners alike to appreciate the scope of operations.

A successful mining operation requires years of planning, massive capital investment, and rigorous adherence to environmental standards. Whether you are involved in exploration, engineering, or the supply of critical consumables like those provided by Alpha Grinding Media, recognizing where you fit into this lifecycle is key. This article outlines the step-by-step progression of a mine.

Prospecting and Exploration: The Beginning of the Stages of a Mining Cycle

Every mine begins with an idea and a search. The first of the stages of a mining project is known as prospecting and exploration. This phase is all about discovery. Before any heavy machinery is brought in, geologists must locate an ore body that is worth extracting.

This stage often starts with research. Geologists review geological maps and historical data to identify areas with high mineral potential. Once a target area is selected, the physical work begins. This involves geochemical analysis of soil and water samples, aerial surveys to detect magnetic anomalies, and detailed ground mapping.

If surface results are promising, the project moves to advanced exploration, which involves diamond drilling. Drills extract core samples from deep underground to determine the presence of mineralization. This is arguably the most high-risk phase among the stages of a mining lifecycle, as many exploration projects do not result in a commercially viable mine.

Resource Evaluation and Feasibility Studies

- Once a mineral deposit is identified, the question shifts from “is there anything there?” to “can we make a profit from it?” This leads us to the second of the critical stages of a mining venture: resource evaluation and feasibility.

In this phase, the data collected during exploration is handed over to engineers and financial analysts. They must determine the “grade” (quality) and “tonnage” (quantity) of the deposit. A mineral resource is only considered an “ore reserve” if it can be legally and economically extracted.

The feasibility study is a comprehensive document that assesses: - Technical viability: Can we physically mine this rock?

- Economic viability: Will the revenue cover the costs of extraction and processing?

- Legal and Environmental factors: Can we get the necessary permits?

This is a “go or no-go” point. Decisions made during these stages of a mining project determine the future of the entire operation. If the feasibility study is positive, the company seeks financing and moves toward development.

Development, Design, and Construction

- marked by the construction phase. This is often the period of highest capital expenditure. Before a single ounce of gold or ton of copper is produced, the infrastructure must be built.

This stage involves two main components: - Mine Design: Engineers finalize the plan for the mine layout. For open-pit mines, this means designing the pit walls and haul roads. For underground mines, it involves planning the shafts and ventilation tunnels.

- Construction: This involves building the processing plant, administrative offices, maintenance workshops, and necessary infrastructure like power lines, water supply systems, and access roads.

Construction can take several years depending on the location and size of the project. It is a period of intense activity where the site is transformed from a quiet landscape into a bustling industrial zone, preparing for the active stages of a mining operation.

Production and Processing: The Most Active Stages of a Mining Operation

When construction is complete, the mine enters the production phase. This is the longest and most significant part of the lifecycle, where the actual return on investment is generated. Among the various stages of a mining project, this is where companies like Alpha Grinding Media play a vital role.

Production is generally divided into two main activities: Extraction and Processing.

Extraction

This involves removing the ore from the earth. Depending on the deposit’s depth, this is done via surface mining (open-pit) or underground mining. The ore is blasted, excavated, and hauled to the processing plant.

Mineral Processing (Comminution)

- The extracted rock contains valuable minerals locked inside waste rock. To liberate these minerals, the rock must be crushed and ground into a fine powder. This process is called comminution.

During the processing stages of a mining operation, the efficiency of grinding is paramount. The ore is fed into large tumbling mills (like Ball Mills or SAG Mills). Inside these mills, grinding media such as steel balls are used to pulverize the rock. - [Grinding Balls]: These are essential for reducing the particle size of the ore efficiently. The quality of the balls determines how much energy is consumed and how effectively the mineral is liberated.

- [Grinding Cylpebs]: In some specific milling applications, cylpebs are used to achieve a finer grind.

If the grinding media is of poor quality, it breaks or wears down too quickly, leading to contamination and increased costs. Therefore, selecting high-performance media is a critical operational decision. After grinding, the ore goes through separation processes (like flotation or leaching) to produce a concentrate.

Closure and Rehabilitation: The Final Stages of a Mining Lifecycle

Mining is a temporary land use. Eventually, the ore body is depleted, or it becomes uneconomical to continue extraction. This marks the beginning of the closure and rehabilitation phase, which are the final stages of a mining project.

Modern mining standards dictate that closure planning begins before the mine even opens. The goal is to return the land to a safe, stable, and environmentally sound state. This involves:

- Dismantling processing plants and infrastructure.

- Sealing underground mine entrances.

- Stabilizing waste rock dumps and tailings facilities.

- Replanting native vegetation.

Responsible closure ensures that the site does not pose a risk to the surrounding community or environment. It is a complex process that can continue for years after production has ceased, ensuring the legacy of the stages of a mining project is a positive one.

Optimizing Efficiency During the Operational Stages

For industry professionals, the focus is often on optimizing the active production years. While you cannot control the geology or the global metal prices, you can control operational efficiency.

In the processing plant, the cost of consumables is a major factor. During the comminution stages of a mining operation, the wear rate of grinding media directly impacts the bottom line. Using superior [Chrome Grinding Balls] or [Forged Steel Balls] from Alpha Grinding Media ensures that the mills run longer without interruption, and the grind is consistent. A consistent grind leads to better recovery rates in the subsequent separation stages.

Conclusion

From the initial trek of a geologist across a remote landscape to the final planting of trees on a reclaimed site, the lifecycle of a mine is a testament to human engineering and planning.

The stages of a mining project are interconnected; the success of the production stage depends on the accuracy of the exploration and feasibility stages. For those working in this sector, whether you are a mine manager, a metallurgist, or a procurement officer, understanding this big picture is essential.

At Alpha Grinding Media, we understand the critical nature of the processing stage. By providing high-quality grinding solutions, we help mines navigate the most energy-intensive stages of a mining project with efficiency and reliability.

Frequently Asked Questions

1. How long do the stages of a mining project typically last?

The timeline varies significantly depending on the deposit size and location. Generally, the Exploration phase can take 5 to 10 years. The Construction phase usually lasts 1 to 3 years. The Production phase is the longest, ranging from 10 to over 50 years. Finally, Closure and Rehabilitation can continue for several years after mining ceases.

2. Which of the stages of a mining project requires the most capital investment?

The Development and Construction stage typically requires the highest upfront capital expenditure (CAPEX) to build infrastructure and processing plants. However, the Production stage involves the highest operating expenses (OPEX) over time, where costs for consumables like energy and [Grinding Media] must be managed carefully.

3. Why is the feasibility study considered one of the most critical stages of a mining project?

The feasibility study is the “point of no return.” It determines if the project is economically profitable and technically possible. Without a positive feasibility study, banks and investors will not provide the necessary funding to move into the construction phase.

4. Can a mine skip the rehabilitation stage?

No, modern regulations and ethical standards make rehabilitation mandatory. The stages of a mining lifecycle are not considered complete until the land has been restored. Mining companies must plan and budget for closure from the very beginning to ensure environmental safety and community well-being.