The modern world is built upon the resources extracted from the earth. From the structural steel in skyscrapers to the rare earth elements in smartphones and the copper wiring in electric vehicles, raw materials are the starting point of almost every supply chain. For those looking to enter this sector, understanding the lifecycle of a mine is essential.This article by Alpha Grinding Media provides a detailed mining industry overview, breaking down the complex stages that transform raw earth into valuable commodities.While the visible aspect of mining often involves heavy machinery and vast excavation sites, the reality is a sophisticated integration of geology, engineering, metallurgy, and logistics. A successful mining operation is not merely about extraction; it is about efficiency, safety, and the precise processing of ore.

Phase 1: Exploration and Geology

Every mining project begins long before the first shovel hits the ground. The exploration phase is arguably the most high-risk stage of the mining industry overview. Geologists and geophysicists utilize advanced technology to locate mineral deposits that are economically viable to extract.

This process involves aerial surveys, geochemical analysis of soil samples, and exploratory drilling. The goal is to define the size and quality (grade) of the deposit. Once a deposit is identified, feasibility studies are conducted to determine if the mineral can be extracted profitably, considering environmental factors, location, and processing costs. Only a small fraction of explored sites eventually become operating mines.

Phase 2: Mine Design and Construction

Once a deposit is deemed feasible, the project moves into the design and construction phase. This stage requires significant capital investment and meticulous planning. Engineers must design the mine layout, processing plants, and necessary infrastructure such as roads, power supply, and water management systems.

This phase also involves obtaining the necessary social and environmental licenses to operate. In the modern mining industry overview, sustainability and community engagement are as critical as the engineering blueprints.

Phase 3: Extraction (Mining Operations)

The extraction phase is what most people visualize when discussing mining. Depending on the depth and geometry of the ore body, extraction is generally categorized into two main methods:

Surface Mining

When the ore body is located close to the surface, surface mining methods are employed. The most common form is open-pit mining, where massive amounts of material are removed to expose the ore. This method allows for the use of heavy equipment and generally offers high production rates.

Underground Mining

When the ore body is deep within the earth, underground mining is necessary. This involves creating tunnels and shafts to reach the deposit. Underground operations are complex and require specialized equipment and ventilation systems to ensure worker safety.

Regardless of the method, the objective remains the same: to remove the ore (rock containing valuable minerals) and transport it to the processing plant.

Phase 4: Mineral Processing (Beneficiation)

This is the heart of the operation and a critical component of any mining industry overview. The extracted ore is rarely pure; it is usually mixed with waste rock (gangue). Mineral processing, also known as beneficiation, is the process of separating the valuable minerals from the waste. This stage is where efficiency dictates profitability.

Comminution: Crushing and Grinding

The first step in processing is comminution, which involves reducing the size of the rock to liberate the valuable minerals. This starts with crushing, where large boulders are broken down into smaller rocks.

Following crushing, the material enters the grinding circuit. This is one of the most critical and energy-intensive parts of the process. The ore is fed into large tumbling mills, such as Semi-Autogenous Grinding SAG mills or Ball Mills. Inside these mills, the ore is pulverized into a fine powder.

The efficiency of this stage relies heavily on the quality of the consumables used inside the mill. Specifically, [grinding media] plays a vital role. These are hard spheres, typically made of steel or iron, that tumble inside the mill to crush the ore.

- Cast iron grinding balls are often used for their durability and resistance to wear in specific chemical environments.

- Forged steel grinding balls are renowned for their toughness and impact resistance, making them ideal for mills where high impact breakage is required.

Using the correct media ensures that the ore is ground to the optimal particle size without excessive energy consumption or wear on the equipment.

Separation

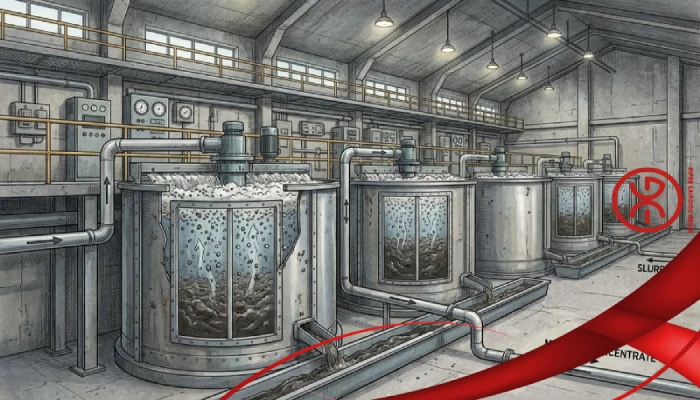

Once the ore is ground to a fine slurry, it undergoes separation. The method depends on the mineral properties:

Froth Flotation: Used widely for sulphides, where chemicals make valuable minerals hydrophobic (water-repelling), allowing them to float to the surface of a tank and be skimmed off.

Gravity Separation: Uses the difference in density to separate heavy minerals from lighter waste.

Magnetic Separation: Utilizes magnets to separate iron-bearing minerals.

Phase 5: Metallurgy and Refining

After separation, the product is a “concentrate.” However, it still requires further processing to become a pure metal. This stage often involves:

- Pyrometallurgy: Using high heat (smelting) to extract the metal.

- Hydrometallurgy: Using aqueous solutions (leaching) to dissolve the metal from the rock.

The final output is a refined metal (cathodes, ingots, or bullion) ready for sale to manufacturers.

Phase 6: Mine Closure and Rehabilitation

A complete mining industry overview must address the end of the mine’s life. Mining is a temporary land use. Once the economically recoverable resources are exhausted, the mine enters the closure phase.

Modern mining standards dictate that the land must be rehabilitated. This involves stabilizing the landform, restoring topsoil, and replanting native vegetation to return the area to a safe and stable condition. Responsible closure is a legacy that defines the reputation of mining companies.

The Importance of the Supply Chain

The mining industry does not operate in a vacuum. It relies on a vast supply chain of manufacturers and service providers. From heavy machinery to chemical reagents, the quality of inputs directly affects the mine’s output.

In the processing plant, for example, the choice of [grinding cylpebs] or balls can significantly impact the “throughput” (the amount of material processed) and the “liberation” (how well the mineral is freed from the rock). Operators must constantly balance cost with performance. Choosing high-quality consumables helps maintain continuous operations and reduces downtime caused by equipment maintenance.

Conclusion

Entering the mining sector offers an opportunity to be part of a fundamental global industry. From the initial geological surveys to the intricate chemistry of processing plants, the scope of work is immense.

A robust mining industry overview reveals that success in this field is driven by technical precision. Whether it is selecting the right mining method or optimizing the grinding circuit with the best available media, every decision impacts the bottom line. For professionals joining this sector, understanding these interconnected phases is the first step toward a successful career in delivering the materials that power our future.

Conclusion

Entering the mining sector offers an opportunity to be part of a fundamental global industry. From the initial geological surveys to the intricate chemistry of processing plants, the scope of work is immense.

A robust mining industry overview reveals that success in this field is driven by technical precision. Whether it is selecting the right mining method or optimizing the grinding circuit with the best available media, every decision impacts the bottom line. For professionals joining this sector, understanding these interconnected phases is the first step toward a successful career in delivering the materials that power our future.

Frequently Asked Questions

1. What are the main stages of the mining industry?

The mining industry consists of several key stages, including mineral exploration, mine design and construction, extraction (surface or underground mining), mineral processing, metallurgy and refining, and finally mine closure and rehabilitation.

2. What is the difference between surface mining and underground mining?

Surface mining is used when mineral deposits are located close to the earth’s surface and allows for high production rates. Underground mining is required for deeper deposits and involves tunnels, shafts, and specialized safety systems.

3. Why is mineral processing important in mining operations?

Mineral processing is essential because it separates valuable minerals from waste rock. Efficient processing improves metal recovery, reduces energy consumption, and directly impacts the profitability of a mining operation.

4. Why is mine closure and rehabilitation important?

Mine closure and rehabilitation are important to ensure environmental protection, land stability, and community safety. Responsible rehabilitation restores the land for future use and is a critical part of sustainable mining practices.