Mini ball mills are compact, versatile grinding machines designed for small-scale applications, making them ideal for laboratories, research facilities, and small production units. These mills use grinding media, such as steel or ceramic balls, to pulverize materials into fine powders, offering precision and efficiency in industries like pharmaceuticals, ceramics, and material testing. This article from Alpha Grinding media explores what mini ball mills are, how they work, their applications, benefits, and practical strategies for optimizing their performance in small-scale grinding processes.

What Is a Mini Ball Mill?

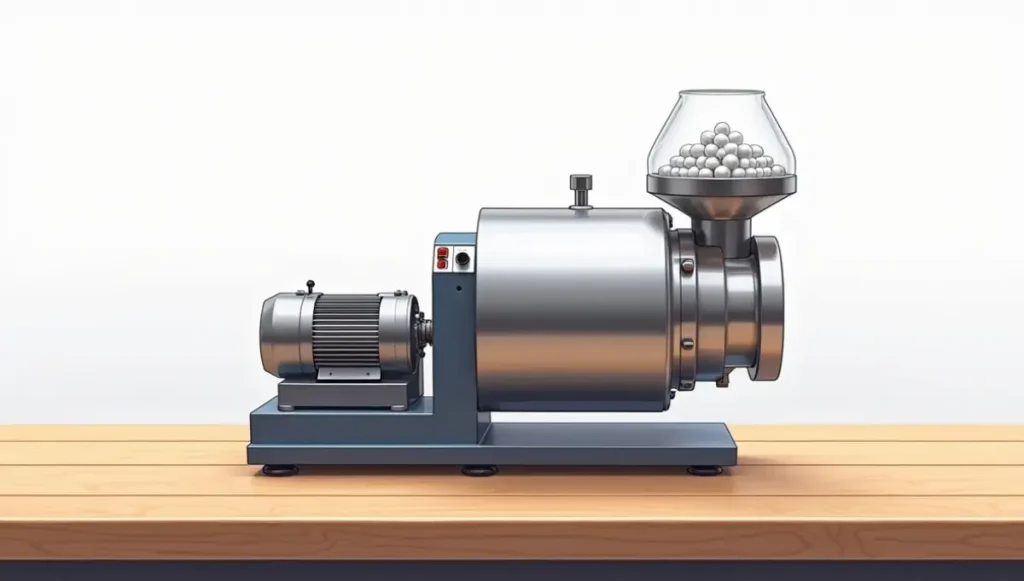

A mini ball mill is a small-scale cylindrical grinding device that uses a rotating drum filled with grinding media—typically steel, ceramic, or zirconia balls—to grind materials into fine particles. Designed for low-volume processing, these mills are compact, easy to operate, and suitable for both wet and dry grinding applications.

Key Components of a Mini Ball Mill

-

Rotating Drum:

A small cylindrical chamber (0.5–10 liters), often lined with rubber, ceramic, or stainless steel to resist wear.

-

Grinding Media:

Balls (5–30 mm) made of steel, ceramic, or zirconia that crush and grind materials through impact and attrition.

-

Drive System:

A motor that rotates the drum at 30–100 RPM, depending on the mill’s size and application.

-

Discharge System:

Ports or screens that allow fine particles to exit, often manually operated in small units.

-

Control Panel:

Allows precise control of rotation speed, time, and sometimes temperature for sensitive materials.

Types of Mini Ball Mills

-

Planetary Mini Ball Mills:

Use multiple rotating drums on a rotating platform for high-energy grinding, ideal for nanotechnology and ultra-fine powders.

-

Jar Mills:

Simple single-drum mills for batch processing, common in laboratories.

-

Vibratory Mini Ball Mills:

Use vibration to enhance grinding efficiency, suitable for fine grinding in small batches.

Mini ball mills are perfect for applications requiring precision grinding in controlled, small-scale environments.

How Mini Ball Mills Work

Mini ball mills operate by rotating a drum or jar filled with grinding media and the material to be processed. The rotation causes the media to tumble, creating impact and attrition forces that reduce particle size and mix the material.

-

Impact Grinding:

The media collides with the material, breaking it into smaller particles through mechanical impact.

-

Attrition Grinding:

Friction between media particles and the material further reduces particle size through abrasion.

-

Rotation Speed:

Operates at 60–80% of critical speed (Nc = 42.3/√D, where D is the drum diameter in meters), typically 50–100 RPM for small drums.

-

Wet or Dry Operation:

Can process materials as dry powders or in a liquid slurry, depending on the application.

-

Batch Processing:

Most mini ball mills operate in batch mode, processing small quantities (e.g., 100 g to 5 kg) at a time.

For example, in a laboratory setting, a mini ball mill might rotate at 80 RPM, using 10 mm ceramic balls to grind a 500 g batch of pharmaceutical compounds into particles below 5 micrometers.

Applications of Mini Ball Mills

Mini ball mills are widely used in small-scale and research applications due to their compact size and precision. Key applications include:

1. Laboratory Research

-

Material Testing:

Grinds small samples for analysis, such as alloys, ceramics, or nanomaterials.

Example: A planetary mini ball mill grinds 100 g of graphene to 100 nm for research in advanced materials.

2. Pharmaceutical Industry

-

Drug Development:

Produces fine powders of active pharmaceutical ingredients (APIs) for improved bioavailability in tablets or capsules.

Example: A mini ball mill processes 200 g of an API to 1–5 micrometers in a water-based slurry for drug formulation.

3. Ceramics and Pigments

-

Powder Preparation:

Grinds and mixes clay, pigments, or additives for small-scale ceramic or paint production.

Example: A jar mill produces 1 kg of ceramic glaze with particle sizes below 20 micrometers for artisanal pottery.

4. Chemical Industry

-

Catalyst and Pigment Production:

Grinds chemicals into fine powders for catalysts, pigments, or specialty chemicals.

Example: A vibratory mini ball mill processes 500 g of pigment for high-quality ink formulations.

5. Educational and Small-Scale Production

-

Teaching and Training:

Used in universities for teaching material processing techniques.

-

Small Batches:

Ideal for producing small quantities of powders for niche applications, like custom cosmetics or specialty alloys.

Example: A mini ball mill grinds 1 kg of cosmetic powder for a boutique skincare brand.

Mini ball mills are critical for applications where small-scale, high-precision grinding is required.

Benefits of Mini Ball Mills

Mini ball mills offer several advantages for small-scale and research applications:

-

Compact Size:

Small footprint (e.g., 0.5–1 m²) makes them ideal for labs or small workshops with limited space.

-

Precision Grinding:

Capable of achieving particle sizes down to 1–100 micrometers, perfect for research and high-quality products.

-

Versatility:

Suitable for both wet and dry grinding, handling materials like ceramics, chemicals, and pharmaceuticals.

-

Ease of Use:

Simple controls and batch processing make them accessible for researchers and small-scale producers.

-

Cost-Effectiveness:

Low initial cost and minimal maintenance make them economical for small operations.

These benefits make mini ball mills a valuable tool for laboratories and niche production.

Conclusion

Mini ball mills are highly effective, compact grinding machines tailored for small-scale applications in laboratories, research facilities, and niche production units. Their ability to precisely grind materials into fine powders (down to 1–100 micrometers) using steel, ceramic, or zirconia media makes them indispensable in industries such as pharmaceuticals, ceramics, chemicals, and material testing. With versatile designs like planetary, jar, or vibratory mills, they support both wet and dry grinding, offering flexibility for diverse applications. Their compact size, ease of use, cost-effectiveness, and precision make mini ball mills an ideal choice for researchers and small-scale producers seeking efficient and reliable grinding solutions.