Comminution in mineral processing is a crucial step in the mining and extraction of valuable minerals. It refers to the process of breaking down ore into smaller, manageable particles to liberate minerals from the surrounding gangue. Without effective comminution, subsequent processing methods like flotation, gravity separation, and leaching cannot operate efficiently. In fact, comminution often accounts for nearly half of the total energy consumed in a mineral processing plant, highlighting its importance for operational cost and efficiency.

Whether dealing with copper, gold, iron ore, or industrial minerals, understanding the principles of comminution in mineral processing is essential for engineers, plant operators, and researchers. The correct application of crushing and grinding techniques directly affects the efficiency of downstream separation processes, energy consumption, and equipment lifespan. Companies like alpha grinding media provide high-quality grinding media that enhance mill performance and reduce wear, contributing to optimized comminution processes.

What is Comminution?

Comminution is the mechanical reduction of particle size in ore. It involves two main stages: crushing and grinding. Crushing reduces large chunks of ore into smaller fragments depending on the crusher type and ore hardness, typically a few centimeters in size, making the material suitable for milling. Grinding then reduces the material further, producing fine particles that allow the liberation of valuable minerals.

The main purpose of comminution in mineral processing is to achieve mineral liberation efficiently. By controlling particle size and uniformity, plants can improve recovery rates and reduce energy consumption. Proper comminution ensures that minerals are released from the host rock in an optimal size range, preventing losses and improving the efficiency of downstream separation equipment.

The Importance of Comminution

Efficient comminution in mineral processing is not only about reducing particle size; it plays a vital role in the overall performance of a mineral processing plant. Smaller particle sizes increase the surface area of the ore, which enhances chemical reactions during processes like leaching and flotation. Furthermore, controlled particle size ensures smooth operation of pumps, classifiers, and separators, preventing blockages and reducing wear on equipment.

When comminution is poorly executed, recovery rates drop, energy consumption rises, and operational costs increase. In addition, oversized particles can lead to underperformance in flotation cells or gravity separators, while excessively fine particles can cause slurry handling problems and loss of valuable minerals.

Mechanisms of Comminution

The process of comminution in mineral processing relies on different mechanisms of particle breakage, including compression, impact, attrition, and shear. Compression occurs when ore is squeezed between two surfaces, such as in jaw or cone crushers. Impact breakage happens when particles are struck at high speed, commonly in hammer mills or impact crushers. Attrition and impact are the dominant mechanisms in ball mills. while shear forces cut particles along their grain structure.

Each mechanism produces different particle shapes and size distributions, affecting the efficiency of subsequent processing steps. Understanding these mechanisms allows plant engineers to select the most suitable equipment for the ore type and desired product size.

Types of Comminution Equipment

Comminution equipment is generally divided into crushing and grinding machines. Crushing equipment, such as jaw crushers and cone crushers, reduces large rocks into smaller fragments. Jaw crushers are commonly used in the primary stage for their ability to handle very large ore blocks, while cone crushers are used for secondary or tertiary crushing to produce more uniform particle sizes.

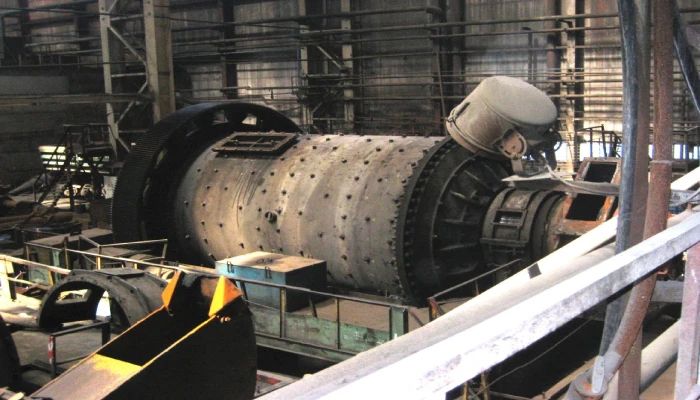

Grinding equipment further reduces particle size and includes ball mills, rod mills, semi-autogenous (SAG) mills, and stirred mills. Ball mills are widely used in various mineral processing plants, often in combination with high-quality grinding media supplied by companies like alpha grinding media, which ensure efficient energy transfer and reduced wear. SAG mills combine the ore itself with grinding media to create a semi-autogenous grinding effect, ideal for high-capacity operations. Stirred mills are typically used for fine or ultra-fine grinding applications, providing precise particle size control for sensitive minerals.

Factors Affecting Comminution Efficiency

Several factors influence the efficiency of comminution in mineral processing. Ore hardness is one of the most critical, as harder ores require more energy to break down. Feed size also plays a significant role: oversized feed increases mill workload and reduces overall efficiency. Moisture content can impact grinding performance by causing particles to stick and form clumps, reducing the effectiveness of the process.

The quality, size, and shape of grinding media significantly affect performance in ball and SAG mills. High-quality grinding media improves mineral liberation, reduces wear on mill liners, and enhances throughput. Mill speed and load are additional operational factors; optimizing these ensures maximum energy transfer to the ore and consistent particle size distribution.

Energy Considerations in Comminution

Energy consumption is a major concern in comminution in mineral processing. Grinding alone can account for a substantial portion of plant energy use. Reducing energy consumption without compromising liberation is a key challenge for engineers. Strategies to improve efficiency include optimizing mill load, using high-performance grinding media, incorporating advanced automation, pre-concentrating ore before grinding, and applying modern equipment like high-pressure grinding rolls HPGRs are used as energy-efficient alternatives to SAG or secondary crushing, applying compressive forces that generate micro-cracks for easier downstream grinding.

Efficient comminution not only lowers energy costs but also contributes to environmental sustainability by reducing greenhouse gas emissions associated with energy production.

Mineral Liberation and Particle Size Control

The ultimate goal of comminution in mineral processing is mineral liberation. Finer particles allow separation methods like flotation, magnetic separation, or leaching to work effectively. However, over-grinding can produce slimes that are difficult to recover, wasting energy and potentially reducing overall recovery. Therefore, controlling particle size distribution is critical for optimal plant performance.

By achieving the correct balance between particle size reduction and energy consumption, mineral processing plants can maximize recovery rates, reduce grinding energy, and maintain consistent performance across separation circuits.

Safety and Operational Considerations

Safety is paramount in any comminution operation due to the size, weight, and energy of the equipment involved. Proper training, guarding of rotating machinery, and dust control systems are essential to prevent accidents. Regular maintenance of crushers, mills, and conveyors helps avoid unexpected failures and prolongs equipment lifespan. Operators should also monitor vibration, temperature, and noise levels to ensure equipment is running safely and efficiently.

Future Trends in Comminution

The future of comminution in mineral processing is shaped by technological advancements aimed at reducing energy consumption, improving efficiency, and enhancing mineral recovery. Some emerging trends include automation and digital monitoring of grinding circuits, use of AI for process optimization, hybrid comminution circuits combining HPGRs and ball mills, and innovative grinding media that increase efficiency while reducing wear. Renewable-energy-powered grinding and digital twin simulations are also gaining traction in modern mining operations.

Conclusion

In conclusion, comminution in mineral processing is a foundational operation that determines both the efficiency and cost-effectiveness of mineral recovery. By understanding the principles of crushing and grinding, selecting appropriate equipment, and optimizing operational parameters, mining operations can achieve higher recovery rates and lower energy consumption. The use of high-quality grinding media, such as those provided by alpha grinding media, plays a critical role in maximizing mill efficiency and extending equipment life. As the industry advances, adopting energy-efficient, automated, and digitally monitored comminution circuits will continue to shape the future of mineral processing.

Frequently Asked Questions

1. What is the main goal of comminution in mineral processing?

The main goal is to reduce particle size and liberate valuable minerals from their host rock for efficient downstream separation.

2. Which factors influence comminution efficiency?

Ore hardness, feed size, moisture content, grinding media quality, and mill speed all affect efficiency.

3. Why is grinding considered the most energy-intensive part of comminution?

Because fine particle size reduction requires significant mechanical energy to break hard mineral bonds.

4. How can plants optimize comminution performance?

By using high-quality grinding media, controlling operational parameters, pre-concentrating ore, and incorporating energy-efficient grinding equipment.