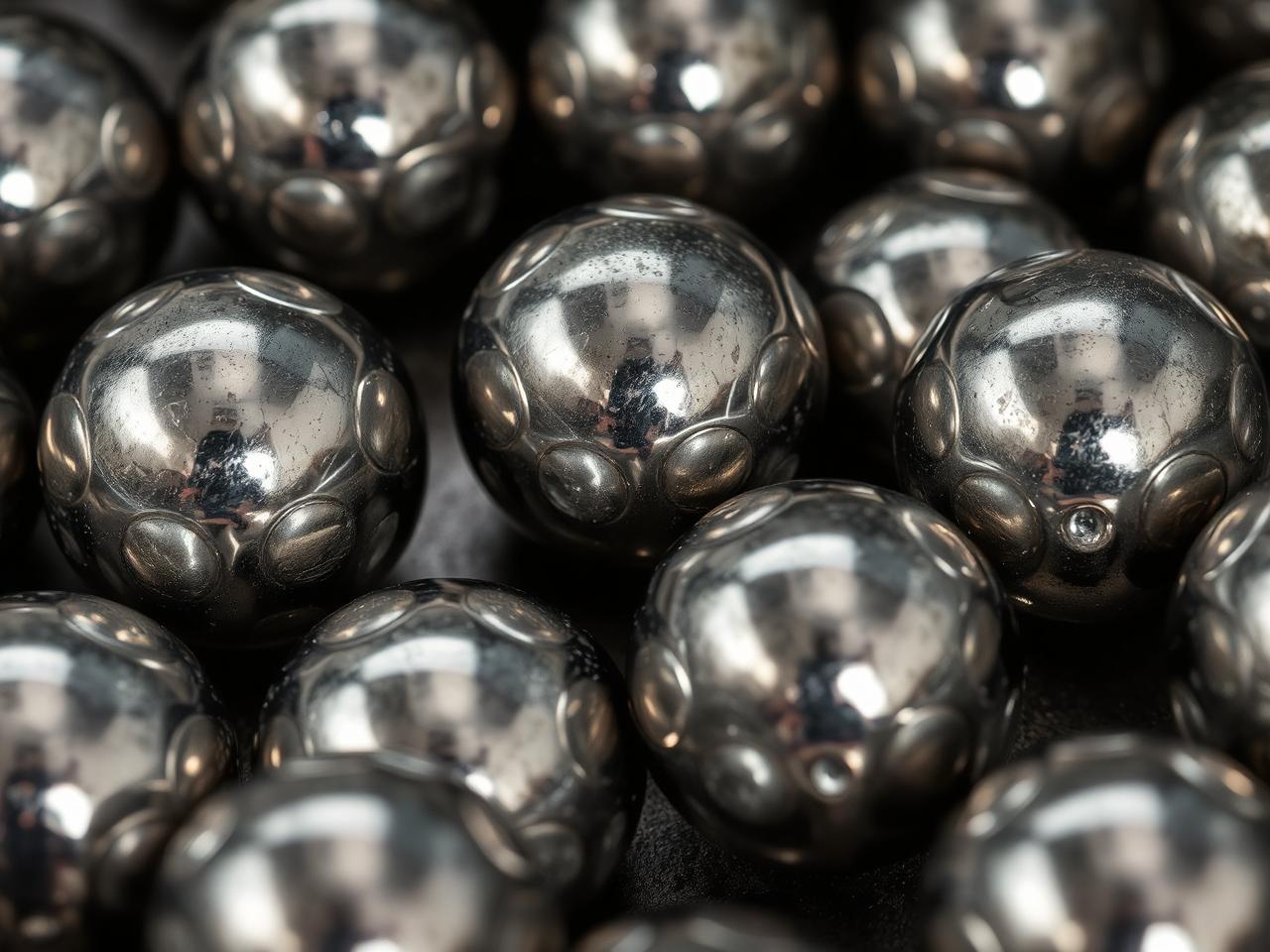

Steel balls, also known as bearing balls or ball bearings, are used across a wide range of industries due to their exceptional durability, high strength, and corrosion resistance. These characteristics make them indispensable in various manufacturing processes and mechanical systems. In this article, we will explore the different types of steel balls and their specific applications.

Types of Steel Balls

Steel balls are manufactured in various sizes, shapes, and materials to meet diverse industrial needs. Here are some of the main types:

-

Precision Steel Balls

Precision steel balls are known for their outstanding uniformity in size and shape. These are widely used in aerospace, medical devices, and precision machinery, where minimal dimensional variation is critical for performance.

-

Chrome Steel Balls

Chrome steel balls are alloyed with chromium to enhance wear and corrosion resistance. They are commonly used in the automotive industry, especially in bearings, joints, and other mechanical components.

-

Stainless Steel Balls

Stainless steel balls contain chromium, offering excellent corrosion resistance. They are ideal for use in food processing, pharmaceuticals, and chemical industries where hygiene and contamination control are essential.

-

Carbon Steel Balls

Carbon steel balls are known for their toughness and cost-effectiveness. These are commonly used in bicycle parts, caster wheels, and conveyor systems, making them a popular choice across various sectors due to their wear resistance and affordability.

-

Hollow Steel Balls

Hollow steel balls are precisely machined internally and are used in decorative applications, architectural designs, and as floats in valves and fluid control systems. They are especially useful where a lightweight component is required without compromising force efficiency.

-

Ceramic Balls

Made from materials like silicon nitride (Si₃N₄) or zirconia (ZrO₂), ceramic balls possess exceptional hardness, low friction, and superior wear resistance. These can operate at higher speeds and temperatures than steel balls and are often used in high-speed bearing systems.

-

Plastic Balls

Manufactured from various plastics like polyethylene (PE) or polypropylene (PP), plastic balls are lightweight, corrosion-resistant, and offer electrical insulation. They are suitable for low-load, low-speed applications.

-

Hybrid Balls

Hybrid balls combine two different materials, such as ceramic and steel, to utilize the advantages of both. For example, ceramic provides low friction and high-speed capabilities, while steel contributes wear resistance. These are ideal for use in high-speed bearing applications.

Industrial Applications of Steel Balls

Steel balls are widely utilized across various industries due to their high durability, resistance to wear and corrosion, and exceptional precision. Let’s explore the key industrial sectors where steel balls play a crucial role in enhancing performance, reliability, and product quality:

1. Bearings

One of the most common applications of steel balls is in ball bearings. Used in vehicles, industrial equipment, and machinery, these balls help reduce friction and enable smooth rotational movement. Precision steel balls are particularly important in high-performance bearings, ensuring minimal resistance during rotation and enhancing mechanical efficiency.

2. Automotive Industry

Steel balls are essential components in the automotive sector, found in wheel bearings, CV joints, powertrain systems, and steering columns. They contribute significantly to vehicle safety, performance, and energy efficiency.

3. Manufacturing and Machinery

In production lines and machinery, steel balls support material handling systems and motion control components. Their high load-bearing capacity and resistance to abrasion make them ideal for conveyors, rollers, and automated mechanisms.

4. Aerospace Industry

Precision steel balls are used in aerospace applications, such as aircraft turbines, engine components, and propeller systems. Their ability to withstand extreme temperatures and friction ensures consistent performance and safety in critical flight operations.

5. Food Processing

Stainless steel balls are commonly used in food processing equipment where hygiene is vital. They resist corrosion and endure harsh cleaning procedures, ensuring that food remains uncontaminated and equipment meets sanitary standards.

6. Medical Equipment

High-precision steel balls are integral to medical devices, including surgical instruments, diagnostic tools, and medical pumps. Their accuracy and reliability are vital for the safe and effective operation of these sensitive devices.

7. Oil and Gas Industry

Steel balls are found in valves, pumps, and control systems within the oil and gas industry. Designed to withstand high pressure and corrosive environments, they help manage fluid flow and maintain operational safety.

8. Electronics and Technology

Miniature steel balls are used in electronic devices such as hard drives, printers, and precision motors. Their smooth surfaces and exact dimensions support seamless performance and longevity in sensitive components.

Conclusion

Steel balls are versatile elements that contribute to improved performance, safety, and reliability across numerous industries. Selecting the right type and quality of steel ball is crucial for specific applications, especially as industries advance and require greater precision. As innovation continues, steel balls remain a key part of modern industrial success, driving both technological progress and product quality.

1. What are the main differences between ceramic balls and steel balls?

Ceramic balls are typically made from materials like silicon nitride or zirconia, making them lighter, harder, and more resistant to heat and corrosion compared to steel balls. Steel balls, usually made from chrome or stainless steel, are heavier, less expensive, and better suited for high-load applications.

2. Which type of ball is better for high-speed applications?

Ceramic balls are better for high-speed applications because of their lighter weight and lower friction. This reduces heat generation and wear, making them ideal for high-performance bearings and precision instruments.

3. Are ceramic balls more durable than steel balls?

Yes, ceramic balls are generally more durable in harsh environments. They resist wear, corrosion, and thermal expansion better than steel balls, although they can be more brittle under sudden impact.

4. When should I choose steel balls instead of ceramic balls?

Steel balls are a better choice when cost is a major factor or when high load capacity is needed in less demanding environments. They’re commonly used in automotive, industrial machinery, and other applications where extreme heat or corrosion resistance is not required.