Caustic soda, also known as sodium hydroxide (NaOH), is a highly corrosive and versatile chemical compound made up of sodium cations (Na+) and hydroxide anions (OH-). This compound is widely recognized by various names, including lye, caustic soda, sodium hydroxide hydrate, and soda lye. It plays a vital role across many industries, such as gas, oil, food production, and manufacturing. Its primary applications include its use in soap production, the synthesis of organic compounds, the creation of salts, and as a pH regulator. This article from Alpha Grinding Media offers insight into the production, properties, and various uses of caustic soda.

Properties of Caustic Soda (Sodium Hydroxide)

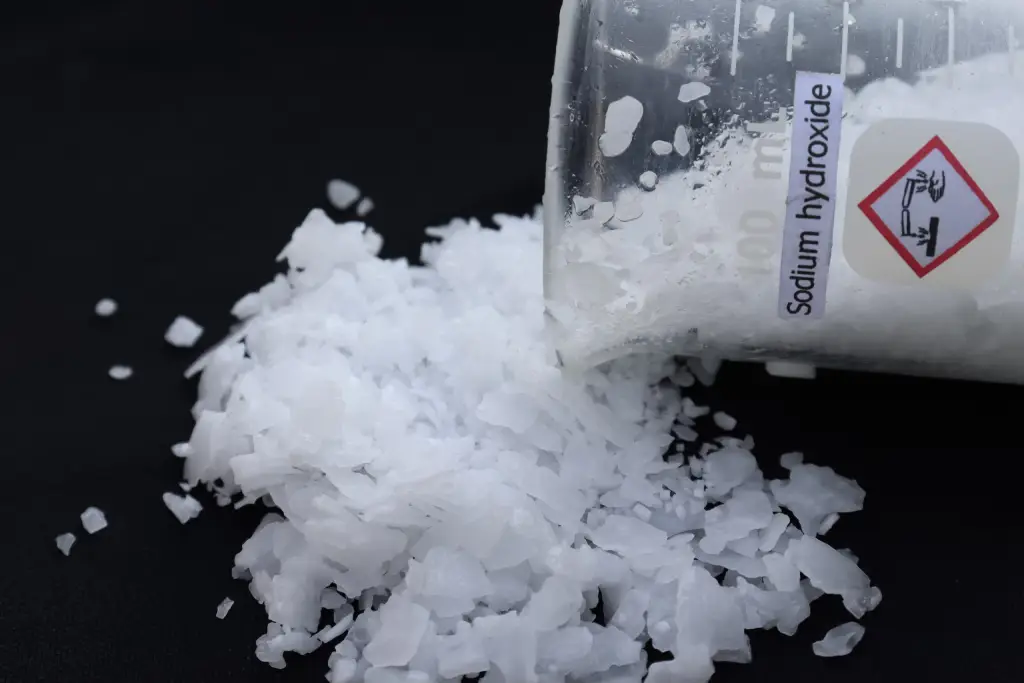

Sodium hydroxide is a white, odorless solid that is highly hygroscopic. It can absorb moisture and carbon dioxide from the air. When dissolved in water, caustic soda releases a large amount of heat. Additionally, when it reacts with acids, it generates significant heat, which facilitates higher solubility in both water and acids.

Caustic soda dissociates in water into sodium ions (Na+) and hydroxide ions (OH-) and is considered a strong base.

Types of Caustic Soda

Caustic soda is produced in two main forms: solid and liquid.

Caustic Soda Solid:

Known as caustic soda flakes or sodium hydroxide pellets, this solid form is obtained by evaporating 50% sodium hydroxide solution in the petrochemical industry. It is widely used in industries like aluminum manufacturing, textile production, soap making, and paper production.

Caustic Soda Liquid:

The liquid form is a strong, clear solution that can break down proteins at room temperature, making it highly corrosive and capable of causing severe burns. This form is used in industries such as dyeing, leather processing, textiles, pharmaceuticals, and food processing.

Production of Sodium Hydroxide

One of the most common methods for producing caustic soda is the chlor-alkali process, which involves the electrolysis of sodium chloride (NaCl). This process separates sodium ions from chloride ions to produce chlorine gas and sodium hydroxide. The majority of sodium hydroxide used in industry is produced through this method. The electrolysis process can be conducted using mercury cells, diaphragm cells, or membrane cells, each with varying energy consumption and quality of product. The membrane cell process is the most commonly used today due to its economic viability.

Chemical Reactions of Caustic Soda

Caustic soda can react with acidic compounds, such as acids and acidic oxides, and can even react with certain metals and non-metals. For instance:

- Reaction with Acids: Caustic soda neutralizes acids to produce water and salts. A common reaction is the neutralization of hydrochloric acid to form sodium chloride and water.

- Reaction with Acidic Oxides: For example, when sodium hydroxide reacts with sulfur dioxide (SO2), sodium sulfite is produced.

- Reaction with Metals: Certain metals, like aluminum, react with sodium hydroxide, producing hydrogen gas.

Applications of Caustic Soda

- Oil and Gas Industry: Caustic soda plays a significant role in the oil and gas industry, especially in drilling operations. It is used to adjust the pH and viscosity of drilling fluids. Caustic soda helps neutralize harmful gases and aids in removing impurities such as sulfur compounds and carbon dioxide from oil products.

- Water Treatment: In water treatment, caustic soda is used to soften hard water by reacting with calcium and magnesium ions to form insoluble carbonates, thus reducing the hardness of water.

- Pulp and Paper Industry: Sodium hydroxide is used in the paper industry to break down wood fibers and remove lignin, a key component in the production of pulp and paper.

- Soap and Detergent Production: Sodium hydroxide is essential in soap-making processes. It is used for saponification, where fats and oils are converted into soap through the action of sodium hydroxide.

- Textile Industry: Caustic soda is used in textile processing, including bleaching and mercerizing, to improve fabric strength and dyeability.

- Chemical Synthesis: Caustic soda is a critical component in the production of various chemicals, including synthetic detergents, plastics, and more.

- Food Industry: In food processing, caustic soda is used for peeling fruits and vegetables, as well as in other applications where high pH is required.

Types of Caustic Soda and Their Specific Uses

- Different caustic soda products are formulated to meet various industrial needs, such as food-grade caustic soda, which is used in food processing, and industrial-grade caustic soda for applications like soap-making and chemical production.

- Caustic soda liquid is typically preferred in applications that require easy handling and flow, such as textile production or the petroleum industry, while caustic soda flakes are more suited for situations that require solid forms or where high concentrations are necessary.

Conclusion

Caustic soda is an essential chemical compound with a broad range of applications across various industries. Understanding the different types of caustic soda and their properties can help in selecting the most suitable form for specific industrial processes.

For more detailed information or to purchase different types of caustic soda, you can contact Alpha Grinding Media, who also offer expert support in selecting the right caustic soda for your needs.

Frequently Asked Questions

1. What are the different types of caustic soda?

There are two main types of caustic soda: solid caustic soda and liquid caustic soda.

- Solid Caustic Soda (Caustic Soda Pearls or Flakes): This form is a white, crystalline substance typically produced by evaporating liquid caustic soda. It is highly concentrated, with a purity of 98-99%, and is commonly used in industries like aluminum manufacturing, paper production, and soap-making.

- Liquid Caustic Soda (Caustic Soda Solution): Liquid caustic soda is a clear, colorless solution that is less concentrated (usually around 50%). It is widely used in industries such as textile processing, petroleum refining, and cleaning. Liquid caustic soda is easier to handle and more versatile for certain applications.

2. How is caustic soda produced?

Caustic soda is primarily produced through the chlor-alkali process by the electrolysis of sodium chloride (salt) in water. This method generates both caustic soda (NaOH) and chlorine gas (Cl2). There are three main electrolytic cell technologies for caustic soda production:

- Mercury Cell Process: Produces high-purity caustic soda but is less commonly used today due to environmental concerns.

- Diaphragm Cell Process: Generates lower-purity caustic soda and is more energy-efficient compared to the mercury cell process.

- Membrane Cell Process: The most widely used method today, producing high-purity caustic soda with lower energy consumption.

3. What are the main uses of caustic soda?

Caustic soda is a crucial chemical with a wide range of applications:

- Cleaning and Disinfection: It is commonly used in industrial cleaning to remove grease, oils, and other impurities.

- Soap and Detergent Manufacturing: As a key ingredient in saponification, it helps convert fats and oils into soap.

- Water Treatment: Caustic soda is used to soften water by removing hardness-causing minerals.

- Chemical Synthesis: It is involved in manufacturing products such as synthetic fibers, plastics, and pharmaceuticals.

4. What safety precautions should be taken when handling caustic soda?

Given its highly caustic and corrosive nature, handling caustic soda requires strict safety measures:

- Protective Gear: Always wear gloves, goggles, and protective clothing when working with caustic soda.

- Proper Ventilation: Ensure good ventilation in areas where caustic soda is used, especially when working with liquid forms that can release fumes.

- Emergency Procedures: In case of spills, neutralize the substance immediately with diluted acid (e.g., vinegar) and clean up the area carefully. Always have access to eyewash stations and safety showers in workplaces.