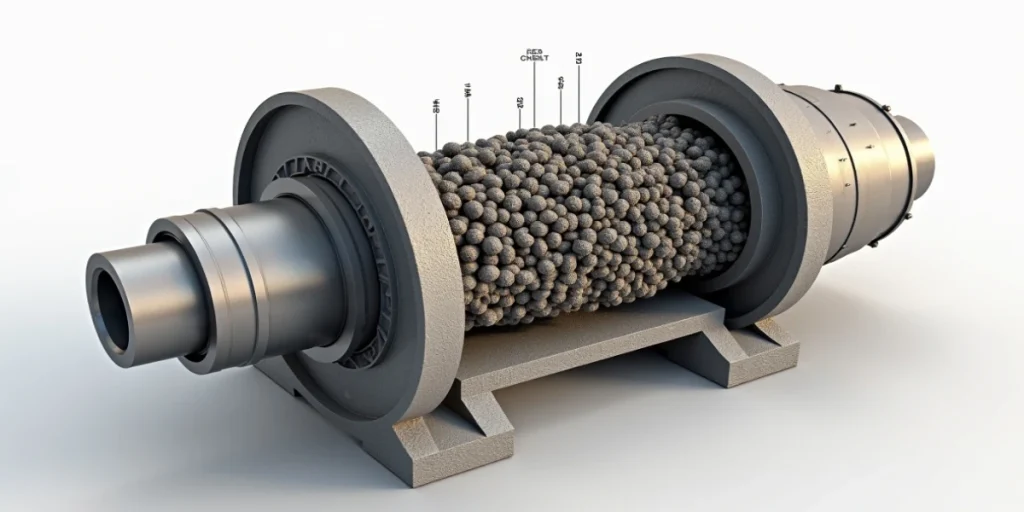

If you’re running a mining operation, a ceramics plant, or even a small lab setup, figuring out the right amount of grinding media for your mill can make all the difference in efficiency and costs. Grinding media. the balls, rods, or beads that do the heavy lifting inside the mill. are essential for breaking down materials, but getting the quantity wrong can lead to wasted energy, uneven particle sizes, or even equipment wear. In this guide, we’ll dive into how much grinding media a mill needs, breaking it down step by step based on mill type, material properties, and real-world factors. Whether you’re optimizing a ball mill for ore processing or a stirred mill for fine pigments, understanding this will help you save time and money. Brands like Alpha Grinding Media offer reliable options tailored for these calculations, ensuring your load performs at its best. Let’s get into it and explore what goes into calculating the perfect load.

Understanding Grinding Media and Its Role in Mills

Before we crunch the numbers on how much grinding media a mill needs, it’s worth stepping back to see why it matters. Grinding media are the consumables that transfer energy to your feedstock, smashing particles through impact, attrition, or shear. In a typical ball mill, for instance, steel balls tumble and cascade, creating the crushing action that reduces ore from chunks to powder. The key is balance: too little media, and your material slips through without enough contact; too much, and the mill chokes, drawing excess power without better results.

From industry standards like those from the Society for Mining, Metallurgy & Exploration (SME), the amount of grinding media directly ties to mill performance. Studies show that optimal loading can boost throughput. For example, in cement production, where ball mills grind clinker, underloading leads to coarser particles and lower quality output. Overloading, on the other hand, spikes wear on liners and increases downtime. So, how much grinding media does a mill need? It boils down to volume fill, which we’ll cover next, but remember: it’s not just quantity.size, density, and shape play huge roles too. Choosing quality media from suppliers like Alpha Grinding Media can make these calculations even more effective, as their products are designed for consistent performance across various loads.

Factors Influencing the Amount of Grinding Media a Mill Needs

No two mills are alike, so the amount of grinding media a mill needs varies based on several key factors. First up is mill type. Stirred media mills, used for ultrafine grinding like in pharmaceuticals.

Material properties are next. The hardness and grindability of your feed—like quartz ore versus limestone—affect how much contact area you need. Softer materials require less aggressive loading to avoid overgrinding, while tough ones demand denser media for better energy transfer. Mill speed and size also factor in: larger diameter mills (say, 5 meters) hold more media proportionally, but slower speeds mean you can load higher without sloshing.

Operating conditions round it out. Wet grinding, common in mineral processing, allows higher fills because slurry lubricates the media. Environmental tweaks, such as adding grinding aids, can let you dial back media for the same fineness. A quick tip: always start with manufacturer specs, but pilot tests refine the exact amount for your setup.

Optimal Loading for Different Mill Types: How Much Grinding Media Does a Mill Need?

Mill type dictates the sweet spot for how much grinding media a mill needs. In overflow ball mills, used for fine grinding in gold recovery, fill ensures good cascading without overflow. SAG mills, blending ore and media, run steel balls by volume, relying on autogenous action for the rest.

Rod mills for coarse crushing load with rods (longer than diameter) to promote linear impact. For vertical stirred mills like those in ultrafine apps, media fill hits because stirring shears particles efficiently.

The Impact of Media Size and Type on Mill Loading Requirements

Size and type tweak how much grinding media a mill needs dramatically. Larger balls for primary grinding need lower fills to tumble freely, while smaller ones for secondary allow for better coverage.

Type matters too: high-chrome options last longer, letting you load less overall . Lighter ceramics for same impact, ideal for contamination-sensitive apps like pharma. Density drives efficiency.

Pro tip: use the Eriez size-energy relationship to predict: smaller media for finer products means more volume to maintain contact. Alpha Grinding Media’s range covers these needs, from chrome alloys to ceramics, so you can match type to your exact loading calc.

Conclusion

Figuring out how much grinding media a mill needs isn’t one-size-fits-all—it’s about balancing type, load, and ops for peak performance. Whether tweaking a ball mill or scaling a stirred one, these insights can transform your process.

Frequently Asked Questions

1. What's the standard fill percentage for a ball mill?

Most ball mills run at 40-50% media volume—start there and adjust based on torque and product fineness.

2. How does media size affect the amount needed?

Larger media (50+ mm) needs lower fills (30-40%) for tumbling; smaller (under 25 mm) allows 50%+ for finer contact.

3. Can overloading a mill improve grinding speed?

No—over 50% fill reduces efficiency by 20-30% due to poor cascading; stick to optimal for best results.

4. How often should I recharge grinding media?

Weekly top-ups of 5-10% maintain gradation; full audits every quarter via sieving.