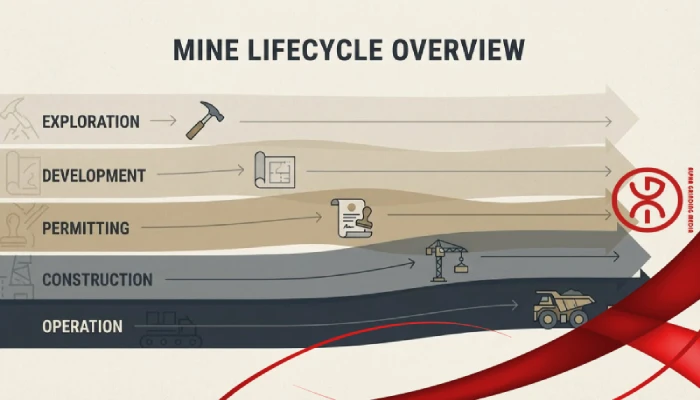

The journey of bringing a new mine into production is one of the most extraordinary industrial endeavors in the modern world. It is a process characterized by immense scale, scientific rigor, and a timeline that spans several decades. Unlike conventional business ventures that can be launched within a few years, a mining project is a generational marathon that requires navigating a complex web of geological, environmental, and engineering challenges.

Understanding the mine opening time is essential for project managers, investors, and stakeholders who are looking to secure the future of global supply chains. At Alpha Grinding Media, we believe that the foundation of a successful mine is laid during these early developmental years. The strategic choices made during the planning phase—especially regarding the quality of processing equipment and industrial consumables—will ultimately dictate the efficiency and profitability of the operation for its entire lifespan.

The High-Stakes World of Mineral Exploration

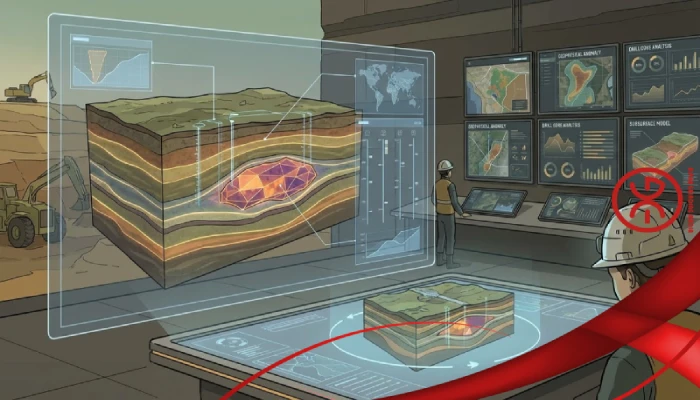

The lifecycle of a mine begins with the exploration phase, a period defined by high uncertainty and vast geographical investigations. Geologists and exploration teams spend many years surveying remote landscapes, analyzing soil samples, and conducting deep-core drilling to identify potential mineral deposits. This is a labor-intensive stage where researchers look for a “needle in a haystack,” as only a tiny fraction of identified mineral occurrences ever show enough potential to be developed into a full-scale mine.

This initial phase accounts for a significant portion of the overall mine opening time. Most exploration projects are eventually abandoned if the mineral grade is too low or the location is too difficult to access. For those projects that do show promise, the data collected must be extremely precise to secure the confidence of global investors. This period of scientific discovery is the first major hurdle in a journey that requires years of patience before any physical extraction can take place.

Feasibility Studies and the Engineering of the Process

Once a deposit is confirmed to be significant, the project enters the feasibility stage. This is where a geological discovery is transformed into a practical, bankable engineering plan. Detailed studies are conducted to model how the ore will be extracted and, more importantly, how it will be processed in the milling circuit.

During this part of the mine opening time, metallurgical testing is performed to understand the hardness and composition of the rock. This data is critical for designing the comminution circuit—the heart of the processing plant where the ore is crushed and ground into fine particles. It is at this stage that engineers make critical decisions about the milling process. Selecting the right types of grinding media solutions, such as forged steel grinding balls or high-performance cast grinding balls, is a key part of this long-term engineering vision. The goal is to design a system that maximizes mineral recovery while minimizing energy consumption and operational wear.

The Permitting Hurdle and the Social License to Operate

In the modern industrial era, the permitting and approval process is often the most time-consuming and complex segment of the mine opening time. To move from a theoretical plan to a physical site, a mining company must satisfy an extensive array of environmental, social, and governmental standards. This is often referred to as securing a “social license to operate.”

Comprehensive environmental impact assessments are required to demonstrate that the mine can operate without causing irreparable harm to the local ecosystem, water sources, and air quality. This phase also involves deep and transparent engagement with local communities and indigenous groups to ensure the project provides local benefits and respects cultural heritage. Because these negotiations and scientific assessments must be so thorough, they can span a long duration, requiring constant communication and a commitment to sustainability from the mining company.

Building the Industrial Foundation: Construction and Infrastructure

Only after all permits are finalized and funding is fully secured can the physical construction begin. A modern mine is much more than a simple excavation; it is a massive, self-sustaining industrial complex often located in the world’s most remote and harshest environments. The construction phase involves developing significant infrastructure from the ground up, including:

- Constructing access roads, heavy-duty rail links, or dedicated ports for the transportation of ore.

- Establishing reliable power grids and water management systems to support heavy industrial machinery.

- Assembling the massive processing plant, including primary crushers and sophisticated secondary milling circuits.

This construction stage represents a major component of the mine opening time, involving a large workforce and complex global logistics. Every day spent in construction is a step closer to the first production run, but it is also a period where the quality of every component—from the heavy steel structures to the smallest consumables—must be verified to ensure the facility can withstand decades of continuous operation.

Operational Readiness and the Role of Commissioning

The final transition before a mine becomes fully active is the commissioning phase. This is the moment where the theoretical designs and months of construction are put to the test. Every piece of equipment, from the smallest motor to the largest mill, is activated and tested under load to ensure it can handle the stress of continuous, high-volume production.

During commissioning, the milling circuits are loaded with the first batches of ore and the selected grinding media. This is the stage where the reliability of products from Alpha Grinding Media becomes evident. Using high-quality grinding rods, balls, or cylpebs ensures that the mill reaches its target efficiency quickly, avoiding the costly delays that occur when inferior materials fail under industrial pressure. This stage marks the successful conclusion of the long development period and the beginning of the productive lifecycle of the mine.

Why Quality Sustains the Long-Term Vision

After a duration that can span several decades, a mining operation cannot afford to be inefficient. The extensive mine opening time means that the initial capital investment is enormous, and the pressure to recover that capital is high. This is why, once the mine is open, the focus must shift from “construction” to “operational excellence.”

The durability of consumables is a silent but critical factor in this success. High-quality grinding media reduce the need for frequent maintenance shutdowns and ensure that the ore is ground to the exact specifications required for chemical recovery. By choosing wear-resistant solutions, a mine can maintain a high throughput and lower its overall cost per ton. This turns years of patient development into a sustainable, profitable, and efficient operation that can serve the global market for many years to come.

Summary and Conclusion

Opening a mine is one of the most complex and long-term human endeavors in the modern industrial world. It requires a vision that balances advanced geological science, environmental responsibility, and world-class engineering. The extensive mine opening time reflects the industry’s commitment to safety, sustainability, and long-term planning.

As the global demand for minerals continues to grow to support new technologies and energy systems, the mining industry must continue to navigate these long timelines with a focus on quality. By making the right strategic choices during the early development years—especially regarding the quality of the materials used in the milling process—mining companies can ensure that when they finally reach the production stage, they are positioned for a future of success, reliability, and growth.

Frequently Asked Questions

1. Is the time to open a mine the same for every type of mineral?

No, the timeline varies significantly depending on the deposit. Some minerals require much more complex chemical processing or are found in deeper underground environments, which naturally extends the time needed for engineering and construction compared to simpler surface operations.

2. Why is the social license to operate such a major part of the timeline?

Modern mining is held to very high social and environmental standards. Building trust with local communities and meeting strict government regulations ensures that the mine can operate for its entire intended lifespan without legal interruptions or social conflict.

3. What is the impact of geography on the time it takes to open a mine?

Mines located in extreme or remote areas require the construction of entire supply chains, including roads and power grids, from scratch. These logistical challenges can add many years to the development process compared to sites located near existing infrastructure.

4. How does the choice of grinding media affect the mine's start-up phase?

High-quality media from Alpha Grinding Media ensure that the milling process is consistent and reliable during the critical first stages of production. This prevents mechanical issues and helps the mine reach its full nameplate capacity much faster and more efficiently.