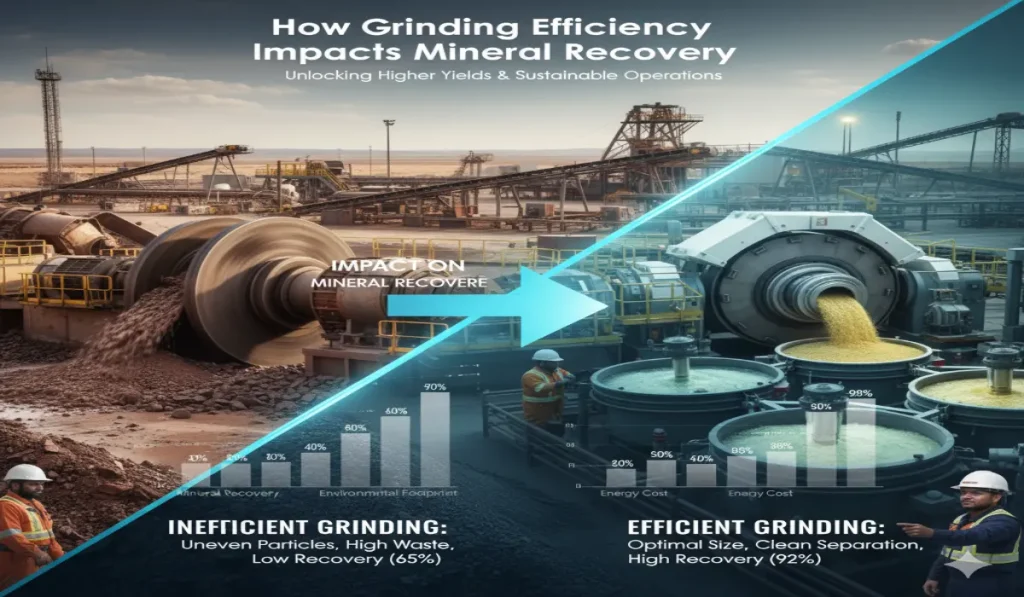

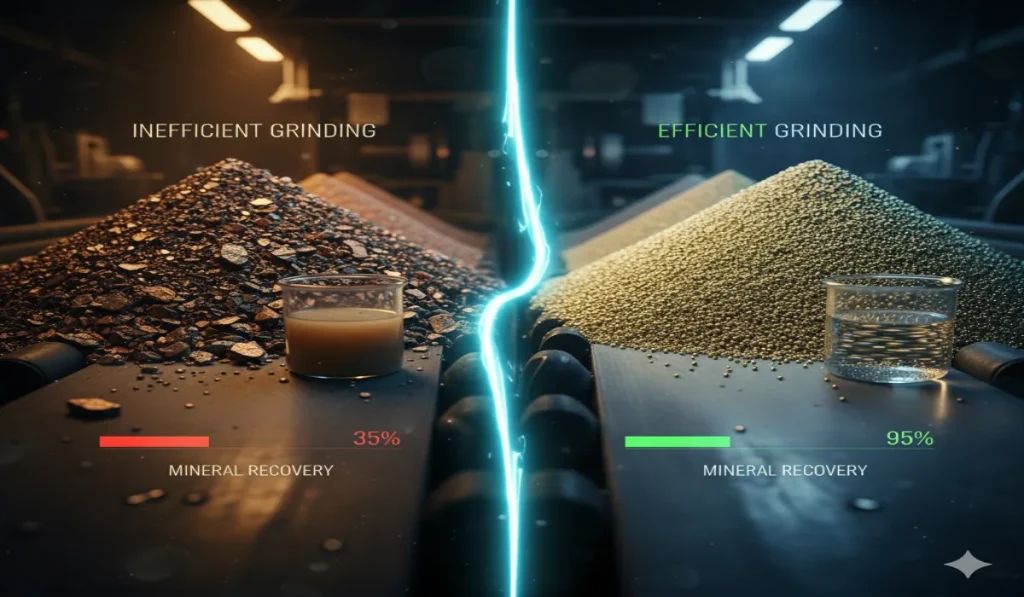

Imagine a mining operation where every ounce of valuable mineral counts, yet up to 20% of potential recovery is lost due to suboptimal processes. In the world of mineral processing, grinding efficiency stands as a pivotal factor that can make or break the success of extracting precious resources from ore. Grinding, the process of reducing ore particles to liberate valuable minerals, directly influences how effectively those minerals can be recovered through subsequent separation techniques like flotation.

Grinding efficiency refers to the ability to achieve the desired particle size distribution with minimal energy consumption and waste. When done right, it enhances mineral liberation, improves selectivity in separation, and boosts overall recovery rates. However, inefficiencies—such as over-grinding or using inappropriate media—can lead to increased energy costs, reduced recovery, and environmental challenges. This article from Alpha Grinding Media delves into how grinding efficiency impacts mineral recovery, exploring key mechanisms, real-world examples, and strategies for optimization. By understanding these dynamics, mining professionals can unlock higher yields and more sustainable operations.

Thesis statement: Optimizing grinding efficiency not only maximizes mineral recovery but also reduces operational costs and environmental footprints, making it essential for modern mining practices.

Understanding Grinding in Mineral Processing

Grinding is a fundamental step in mineral processing, where raw ore is crushed and milled into finer particles to expose valuable minerals embedded within the rock matrix. This process typically occurs in ball mills, rod mills, or semi-autogenous grinding SAG mills, using grinding media like steel balls or ceramic beads to break down the ore.

The primary goal of grinding is mineral liberation—the separation of valuable minerals from gangue (waste material). Efficient grinding ensures that particles are reduced to an optimal size, usually between 10 to 100 micrometers, depending on the ore type. For instance, in copper mining, finer grinding can liberate chalcopyrite from pyrite, facilitating better flotation recovery.

Key aspects of grinding efficiency include:

- Particle Size Distribution: Achieving a uniform size that promotes liberation without creating excessive fines, which can hinder recovery.

- Energy Consumption: Grinding accounts for up to 50% of a mine’s energy use, so efficiency directly affects costs.

- Media Selection: The choice between steel, ceramic, or other media influences breakage rates and surface chemistry.

Inefficient grinding can result in incomplete liberation, where valuable minerals remain locked in larger particles, leading to lower recovery rates in downstream processes. Studies show that dry grinding, while energy-intensive, can sometimes yield higher mass recoveries compared to wet grinding, though at the expense of selectivity. Understanding these basics sets the stage for exploring how efficiency translates to real impacts on recovery.

Factors Affecting Grinding Efficiency

Several factors determine grinding efficiency, each playing a role in how well minerals are prepared for recovery. These include the type of grinding media, mill design, ore characteristics, and operational parameters.

- Grinding Media Type: Steel balls are common, but ceramic media can reduce contamination and improve flotation by minimizing iron dissolution on mineral surfaces. For example, using ceramic balls in scheelite grinding has been shown to enhance recovery by preserving surface properties.

- Ore Hardness and Composition: Harder ores require more energy, potentially lowering efficiency. Magnetite ores, for instance, respond differently to media shapes, with spherical media producing more uniform breakage.

- Mill Speed and Load: Optimal speed ensures effective tumbling, while overloading can cause inefficiencies.

- Grinding Aids: Polysaccharide-based aids can reduce energy use by up to 20% and improve particle fineness, leading to better liberation.

Real-world data from pyrite and chalcopyrite processing indicates that nano-ceramic balls outperform steel in flotation, increasing recovery by altering surface hydrophobicity. At Alpha Grinding Media, we specialize in high-quality media that address these factors, helping clients achieve peak efficiency.

These elements collectively influence how grinding sets up the ore for effective mineral recovery, emphasizing the need for tailored approaches.

Direct Impacts on Mineral Recovery

Several factors determine grinding efficiency, each playing a role in how well minerals are prepared for recovery. These include the type of grinding media, mill design, ore characteristics, and operational parameters.

- Grinding Media Type: Steel balls are common, but ceramic media can reduce contamination and improve flotation by minimizing iron dissolution on mineral surfaces. For example, using ceramic balls in scheelite grinding has been shown to enhance recovery by preserving surface properties.

- Ore Hardness and Composition: Harder ores require more energy, potentially lowering efficiency. Magnetite ores, for instance, respond differently to media shapes, with spherical media producing more uniform breakage.

- Mill Speed and Load: Optimal speed ensures effective tumbling, while overloading can cause inefficiencies.

- Grinding Aids: Polysaccharide-based aids can reduce energy use by up to 20% and improve particle fineness, leading to better liberation.

Real-world data from pyrite and chalcopyrite processing indicates that nano-ceramic balls outperform steel in flotation, increasing recovery by altering surface hydrophobicity. At Alpha Grinding Media, we specialize in high-quality media that address these factors, helping clients achieve peak efficiency.

These elements collectively influence how grinding sets up the ore for effective mineral recovery, emphasizing the need for tailored approaches.

Case Studies and Real-World Examples

Real-world applications illustrate the tangible benefits of grinding efficiency. In a copper mine using traditional steel media, switching to ceramic alternatives increased chalcopyrite recovery by 10% due to reduced pyrite interference. Another example from magnetite ore processing showed that media size optimization reduced power consumption by 15% while enhancing breakage properties, leading to a 12% recovery uplift.

In a large-scale operation handling scheelite, cast iron ball grinding led to higher dissolution and lower recovery, whereas alternatives mitigated this, boosting yields. Grinding circuit efficiency in a zinc-lead mine improved grade and recovery by addressing rate-limiting factors like mill throughput.

These cases highlight how targeted improvements in grinding efficiency can yield significant gains in mineral recovery, often with quick ROI.

Conclusion

In summary, grinding efficiency profoundly impacts mineral recovery by influencing liberation, particle size, and separation efficacy. From reducing energy costs to enhancing flotation performance, efficient grinding is key to sustainable mining. Challenges like over-grinding can be mitigated through smart strategies, leading to higher yields and lower environmental impact.

We recommend assessing your current grinding setup and considering upgrades, such as high-performance media from Alpha Grinding Media. For tailored solutions that boost your recovery rates, contact us today to discuss how we can optimize your operations.

Frequently Asked Questions

1. What is grinding efficiency in mineral processing?

Grinding efficiency measures how effectively ore is reduced to liberate minerals with minimal energy and waste. It directly affects particle size and recovery rates.

2. How does the type of grinding media affect mineral recovery?

Different media, like steel or ceramic, influence surface properties and breakage. Ceramic media often improves flotation by reducing contamination, leading to higher recovery.

3. Can inefficient grinding reduce overall mine profitability?

Yes, it increases energy costs and lowers recovery, potentially cutting profits by 10-20%. Optimizing efficiency can reverse this through better yields.

4. What role do grinding aids play in improving recovery?

Grinding aids reduce energy use and improve particle distribution, enhancing liberation and subsequent mineral recovery in processes like flotation.