Welcome to the Alpha Grinding Media blog; your primary source for understanding the essential machinery that powers modern industry. Today, we are going to unveil a cornerstone of material processing: the ball mill. You have likely seen these large, rotating cylinders at industrial sites, but what exactly happens inside them? How does a simple rotating cylinder turn large rocks into a fine powder?

This guide will familiarize you with the entire process. We will examine the fundamental principles of a ball mill, the vital role of the grinding media (the balls), and the various factors that make this technology so effective. By the end, you will have a clear understanding of how these powerful machines operate and why they are indispensable in so many industries.

Operating Principles of a Ball Mill

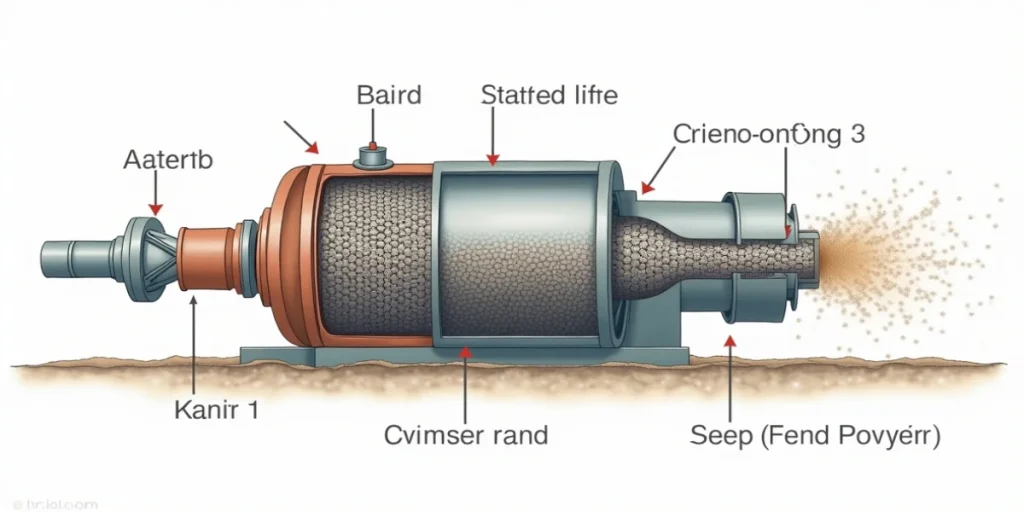

At its core, a ball mill is a grinding device designed to reduce the size of hard materials. It consists of a large, hollow cylindrical shell that rotates on its axis. Inside this shell, there are two key components: the material to be ground and the grinding media—hard, heavy balls from which the mill gets its name.

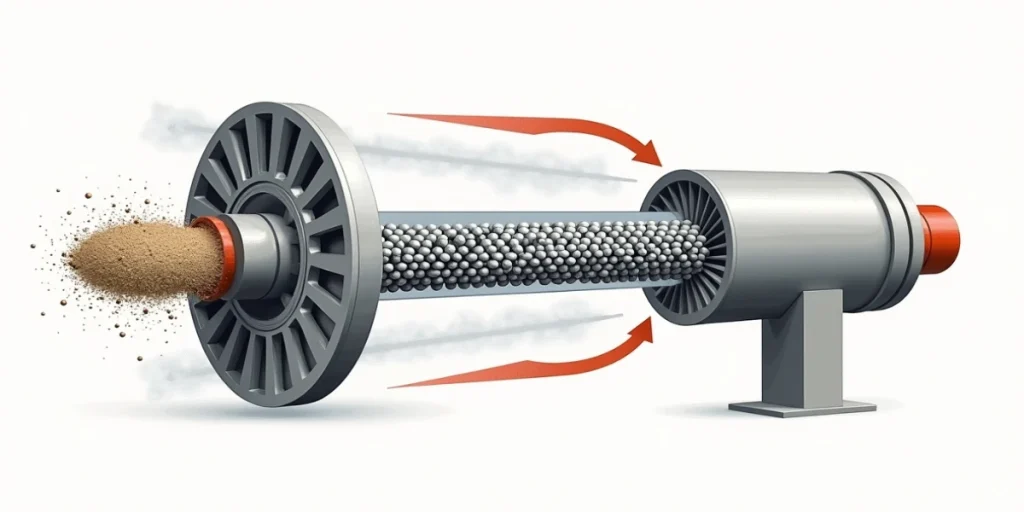

The working principle of a ball mill is surprisingly simple and relies on two main forces: Impact and Attrition.

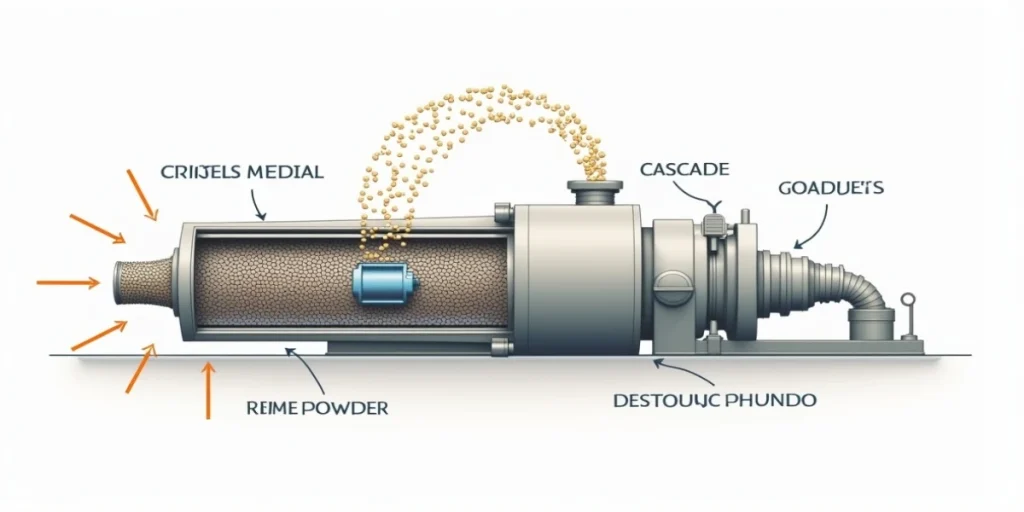

- Rotation and Liftoff: As the cylinder begins to rotate, the grinding balls inside are carried up the side of the shell by the force of friction.

- The Cascading Effect: When the balls reach a certain height, gravity overcomes the rotational force, and they begin to tumble and cascade down onto the material below.

- Impact and Attrition: This is where the magic happens. The falling balls create powerful impact forces, striking the material and breaking it into smaller pieces. Simultaneously, as the balls tumble over each other and the material, they create attrition forces—a rubbing and grinding action that further reduces the particle size.

This continuous cycle of lifting and cascading transforms coarse, solid materials into a fine, uniform powder. The process can be carried out either wet or dry, depending on the material and the desired final product.

The Key Role of Grinding Media (The Balls)

While the mill itself provides the motion, the grinding balls are the real workers of this operation. Without them, the material would simply slide around inside the cylinder with very little size reduction. The characteristics of the grinding balls have a direct impact on the efficiency and effectiveness of the milling process.

At Alpha Grinding Media, we know that not all grinding balls are made the same. The choice of grinding media depends on several factors, including the hardness of the material being ground, the desired final particle size, and the potential for contamination.

Here are some of the common types of grinding media:

- Steel Balls: Made from high-carbon or chromium steel, these types of materials are the most common type of grinding media. They are very hard and dense, making them ideal for grinding hard materials such as minerals and forged steel grinding balls.

- Ceramic Balls: These balls, typically made from alumina or zirconia, are used when contamination from steel is a concern. They are very hard and wear-resistant, making them excellent for grinding sensitive materials in the ceramic, paint, and pharmaceutical industries.

- Rubber Balls: In specific applications, rubber balls are used for a gentler attrition action, often for mixing or dispersing materials without significant size reduction.

The size of the grinding balls is also crucial. Larger balls create a greater impact force, which is effective for breaking down coarse and large particles. On the other hand, smaller balls have a larger surface area and are more efficient for the fine grinding of smaller particles through attrition. A well-designed ball mill often uses a combination of different ball sizes to achieve optimal grinding throughout the process.

Factors Affecting Ball Mill Efficiency

Achieving the perfect grind is a science. Several key factors must be carefully controlled to ensure the ball mill operates at maximum efficiency.

Rotational Speed

The speed at which the cylinder rotates is perhaps the most critical factor.

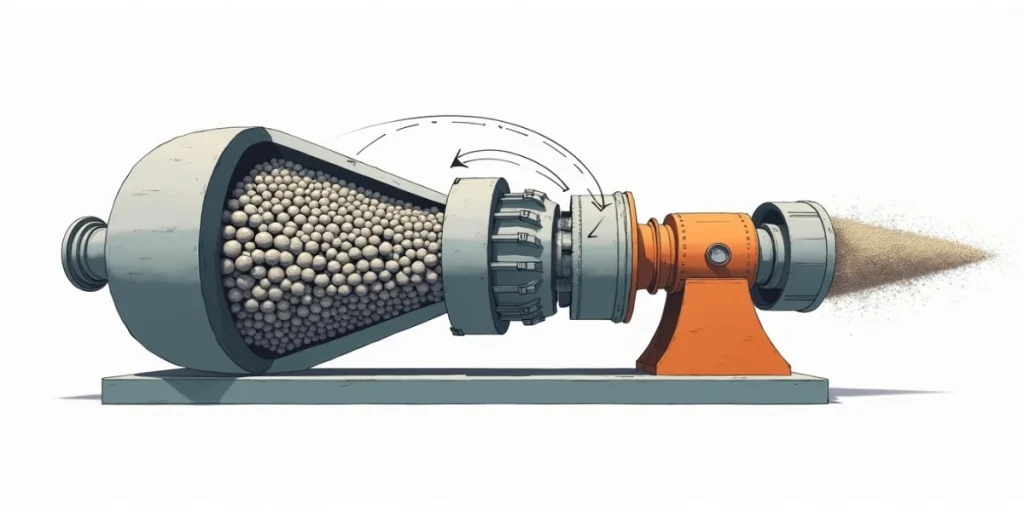

- Too Slow: If the speed is too low, the balls will simply roll over each other at the bottom of the mill, resulting in minimal impact and inefficient grinding.

- Too Fast: If the speed is too high, centrifugal force will pin the balls to the wall of the cylinder, preventing them from cascading. This is known as the “critical speed,” and almost no grinding occurs in this state.

- The Right Speed: The optimal speed is typically between 65% and 75% of the critical speed. This speed allows the balls to be lifted to the highest possible point before cascading, thereby maximizing the impact energy.

Grinding Media Load

The amount of grinding media in the mill, which is called the “charge,” is also important. A typical charge occupies between 30% and 50% of the mill’s internal volume.

Underloading: Too few balls will result in insufficient grinding action and wasted energy.

Overloading: Too many balls will restrict their movement, cushioning the impact and reducing efficiency.

Material Feed Rate

In continuous ball mills, the rate at which new material enters the cylinder must be balanced with the rate at which the ground material is discharged. An incorrect feed rate can lead to either under-grinding or over-grinding, both of which are inefficient.

Common Applications of Ball Mills

The versatility and reliability of ball mills have made them an essential tool in a wide range of industries. Here are just a few examples of their applications:

- Mining and Mineral Processing: Ball mills are the primary tool for grinding large chunks of ore to liberate valuable minerals such as gold, copper, and iron for further processing.

- Cement Production: In the production of cement, ball mills are used to grind clinker—an intermediate product—into the fine powder that we know as cement.

- Ceramics Industry: To produce high-quality ceramics, raw materials like clay, feldspar, and silica must be ground into a very fine and uniform powder. Ball mills are excellent for this task.

- Pharmaceuticals: In the pharmaceutical industry, ball mills are used to grind active ingredients and other compounds to a specific particle size, which is crucial for ensuring the proper dosage and effectiveness of drugs.

- Paints and Pigments: Ball mills are used to grind and mix pigments to ensure a fine and uniform particle size for smooth and vibrant paints.

Conclusion

Ball mills, from their simple design to their powerful performance, have successfully stood the test of time as one of the most effective tools for size reduction. By harnessing the fundamental forces of impact and attrition, these machines can transform even the hardest materials into fine powders.

However, the key to their success lies in the details: the correct rotational speed, the right amount of material, and most importantly, the selection of high-quality grinding balls. At Alpha Grinding Media, we are proud to be a part of this essential process, providing the durable and reliable grinding media that industries around the world depend on.

We hope this guide has given you a clearer picture of the amazing process that occurs inside a ball mill. If you have more questions or are looking for the perfect grinding media for your application, contact the team of experts at Alpha Grinding Media today.