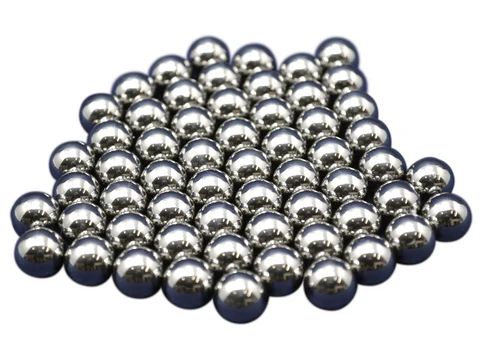

High chrome steel grinding media balls are essential components in grinding mills and milling equipment used in industries like mining, cement, and chemical processing. Known for their excellent wear resistance, high hardness, and low wear rate, these balls ensure consistent performance during the grinding process. The superior quality of high chrome steel grinding media balls improves the overall efficiency and lifespan of grinding equipment, making them ideal for fine powder milling, mineral liberation, and other applications

What Are High Chrome Steel Grinding Media Balls?

High chrome steel grinding media balls are precision-engineered spheres made from high-chromium alloy steel. These balls are designed for applications requiring superior wear resistance and hardness, such as grinding and milling processes in the mining and cement industries. Their high chromium content enhances durability, prevents deformation, and provides resistance to corrosion, making them an excellent choice for both dry and wet grinding environments. These balls are used extensively to process various minerals, including gold, iron, and copper.

Forged steel grinding balls differ from high chrome steel grinding media balls in material composition and manufacturing process. Made from high-quality steel, forged grinding balls are known for their high impact toughness and low breakage rate. These balls are typically used in mills that require heavy-duty grinding in tough environments, particularly in mining operations. While high chrome steel grinding media balls offer superior wear resistance, forged steel balls provide a more cost-effective solution for certain milling applications, especially where extreme durability under high impact is needed.

Advantages of High Chrome Steel Grinding Media Balls

High chrome steel balls and cylpebs are designed to enhance precision and reliability in industrial milling operations. These chrome steel grinding media are engineered with advanced technology to meet a wide range of industrial needs. Infused with chromium, these grinding media offer improved hardness, wear resistance, and corrosion protection compared to standard carbon steel options.

Superior Manufacturing for Enhanced Performance

By utilizing vacuum-degassing technology, trapped air is eliminated during manufacturing, resulting in solid, high-density chrome steel balls that perform reliably in demanding applications.

Optimal Grinding Efficiency

High chrome steel milling balls are specifically designed for use in ball mill grinding, ideal for processing tough raw materials and viscous liquids. Their high density and hardness make them suitable for crushing, mixing, and dispersing in various grinding environments, ensuring efficient and durable milling operations.

Exceptional Hardness and Wear Resistance

These chrome steel grinding media are renowned for their excellent hardness and wear resistance, which enable them to withstand heavy loads and intense grinding conditions. This leads to lower maintenance costs and longer-lasting performance in high-stress applications.

Precision and Consistency

High chrome steel grinding media are engineered for uniform hardness and dimensional accuracy, providing consistent performance across various applications. Their precise control over critical processes enhances the quality and efficiency of operations.

Versatile Applications

These grinding balls are suitable for a wide range of industrial applications, from machining to grinding and assembly. Their reliable performance makes them an indispensable component across various industries.

Cost-Effective and Efficient

With exceptional hardness and wear resistance, high chrome steel grinding balls minimize downtime and maintenance costs, resulting in enhanced productivity and profitability.

Applications of High Chrome Steel Grinding Media Balls

High Chrome Steel Grinding Media Balls are predominantly used in dry grinding and milling operations, especially in industries where corrosion resistance is not a major concern. These balls are commonly found in cement production, metal mining, and processes involving coal slurry, thermal power plants, and various chemical engineering applications. Their exceptional durability and hardness make them ideal for both wet and dry grinding of ores in ball mills and tower mills.

In addition to mining and cement industries, high chrome grinding media balls are also used in the chemical and pharmaceutical sectors due to their excellent wear resistance and ability to withstand deformation under heavy loads.

How to Choose the Right High Chrome Steel Grinding Media Balls

When selecting high chrome steel grinding media balls, consider the following criteria:

- Mill Productivity: Choose media that enhances the productivity of your grinding mill, allowing for efficient operation.

- Cost: Look for a balance between the performance of the grinding media and its cost, ensuring it fits within your budget.

- Material Properties: The grinding media should be hard, wear-resistant, and have a low tendency to crack. Avoid any media with surface burrs or cracks, as these imperfections can affect performance.

Always double-check the specifications and compatibility with your specific grinding processes.

Maintenance and Care for High Chrome Steel Grinding Media Balls

To maintain high chrome steel grinding media balls, regularly check for wear and replace severely worn balls to maintain grinding efficiency and product quality. Implement a routine inspection schedule and consider factors such as the grinding media’s condition, the effectiveness of the heat treatment process used during production, and any changes in your grinding operations that may affect the media’s durability. It’s also essential to ensure proper handling and storage to prevent premature wear.

In summary, High Chrome Steel Grinding Media Balls are essential components in various industries, providing outstanding performance in both dry and wet grinding applications. Their durability, wear resistance, and hardness make them ideal for use in cement manufacturing, metal mining, and chemical processing. For those looking to purchase high-quality grinding media or seeking expert advice, Alpha Grinding Media is an excellent choice, offering a range of products tailored to meet your specific needs.

Frequently Asked Questions

High Chrome Steel Grinding Media Balls are primarily used in the cement and mining industries for both dry and wet grinding applications. They are also utilized in chemical engineering and pharmaceutical processes due to their excellent wear resistance and durability.

High Chrome Grinding Media Balls offer superior hardness and wear resistance compared to standard carbon steel grinding media. This makes them more effective in grinding applications, resulting in improved performance and reduced maintenance costs.

You can purchase High Chrome Steel Grinding Media Balls from various suppliers, including Alpha Grinding Media, which offers a wide selection of high-quality grinding media and expert consultation to help you choose the right product for your needs.