The grinding stage of ore processing stands as one of the most vital and demanding phases in mineral beneficiation. This process reduces coarse ore fragments into finer particles suitable for separation methods. Without proper grinding, valuable minerals stay trapped within waste material, lowering recovery rates.

Today’s mining operations focus heavily on improving this stage. Grinding consumes a major portion of total energy in comminution. Equipment improvements and control strategies have boosted performance, though difficulties remain.

Mastering the grinding stage of ore processing demands insight into physics, metallurgy, and mechanical principles. This article from alpha grinding media explores equipment, steps, influencing factors, and emerging trends in detail.

Why Grinding is Essential in Mineral Processing

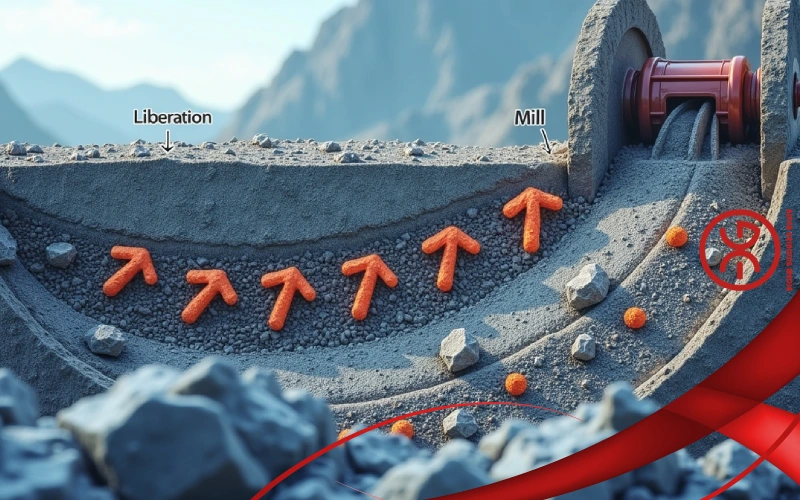

Grinding fulfills two core roles in ore processing. It frees valuable minerals from surrounding rock. It also creates particle sizes ideal for later stages. These roles shape plant profitability and sustainability.

Liberation of Valuable Minerals

Liberation happens when grinding separates minerals along natural grain boundaries. The extent of liberation governs success in flotation, gravity, or magnetic separation. Poor liberation sends precious material to waste.

Ore analysis through microscopy and automated systems determines ideal grind size. Gold ores often need very fine particles for release. Copper deposits require somewhat coarser sizes.

Finer grinding improves liberation but raises energy demands sharply. Finding the right balance drives efficient plant design.

Particle Size Reduction for Downstream Efficiency

Later processes need specific size ranges. Flotation works best with intermediate particles. Coarse material settles poorly in gravity units. Very fine particles create slime that disrupts chemical reactions.

Correct sizing enhances separation in cyclones and screens. It also speeds leaching in heap operations. The grinding stage of ore processing lays the groundwork for entire plant success.

Key Equipment Used in the Grinding Stage

Grinding circuits use different mills based on ore type and capacity needs. Each mill type offers unique benefits in size reduction and energy use.

Ball Mills and SAG Mills

Ball mills serve as reliable tools for fine grinding. Rotating cylinders hold steel balls that tumble and strike ore particles. Modern ball mills reach very fine product sizes in regrind circuits.

Semi-autogenous grinding (SAG) mills use ore pieces as media with added steel balls. They accept larger feed directly from crushers. SAG mills lead primary grinding in major copper and gold plants.

Both require careful management of ball charge and size mix. Liners shield mill shells and shape grinding patterns through their design.

Rod Mills and Autogenous Mills

Rod mills employ steel rods as media. They create more uniform products with fewer ultra-fines than ball mills. Rod milling suits sticky ores that clog ball mills.

Autogenous (AG) mills grind using ore alone. They cut media costs but need strong feed material. Combined SAG/AG setups merge advantages of each.

Role of Grinding Media

Media quality directly shapes mill results. High-chrome steel balls last longer than forged types. ALPHA GRINDING MEDIA supplies premium balls with steady hardness and shape.

Media size matches feed characteristics. Larger balls break coarse material while smaller ones refine fines. Smart media handling extends liner life and limits contamination.

The Grinding Process Step by Step

The grinding stage of ore processing follows a clear sequence. Each phase prepares material for the next to reach desired size distribution.

Feed Preparation and Crushing

Initial crushing breaks large mine-run ore into manageable pieces. Further crushing stages create suitable mill feed. Storage and reclaim systems maintain steady supply.

Ore testing and modeling guide crusher choices. Good fragmentation saves energy in grinding steps.

Primary and Secondary Grinding Circuits

Primary circuits often use SAG or AG mills closed with screens or cyclones. Recycle streams keep mill density optimal. Secondary grinding uses ball mills for finer work.

Circuit layouts range from simple to complex multi-stage designs. Pebble crushing of coarse SAG rejects boosts efficiency. Water addition controls pulp thickness.

Classification and Recycling

Cyclones split fine from coarse particles. Coarse underflow returns for more grinding. Fine overflow moves to concentration. Screens perform similar duties in SAG setups.

Classification sharpness affects capacity and product quality. Cyclone parts need regular tuning. Advanced plants use automated controls for best results.

Factors Influencing Grinding Efficiency

Many variables control grinding circuit performance. Understanding them helps operators raise output while cutting costs.

Ore Hardness and Grindability

Ore resistance to grinding varies widely. Hard materials demand more power than soft ones. Grindability tests forecast energy needs and mill sizing.

Ore changes require flexible circuits. Real-time sensors adjust settings as feed shifts. Early waste removal lightens grinding load.

Mill Speed and Filling Ratio

Best mill speed runs below critical level. Higher speeds raise impact rate but weaken cascade action. Filling level impacts power use and grinding rate.

Power models guide speed choices. Variable drives allow precise tuning to ore conditions. Too much fill drops power and harms efficiency.

Grinding Media Quality and Selection

Media hardness must surpass ore hardness. ALPHA GRINDING MEDIA provides balls with reliable surface strength. Media shape affects breakage patterns.

Round balls deliver better impact than irregular forms. Size mix keeps grinding steady. Proper media use cuts consumption and wear.

Challenges in the Grinding Stage of Ore Processing

Despite progress, grinding circuits face ongoing issues. Solving them needs combined engineering and operational skill.

Energy Consumption

Grinding demands massive power input. Rising energy costs push plants toward efficiency gains. Poor circuit design wastes resources.

Better media selection and process control cut usage. High-pressure grinding rolls offer alternatives in some cases. Energy remains the largest operating expense.

Wear and Maintenance

Mill liners and media wear rapidly with abrasive ores. Frequent stops for replacement raise costs and lower uptime.

Predictive maintenance using vibration and acoustic sensors extends component life. Advanced liner materials resist wear longer. ALPHA GRINDING MEDIA reduces replacement frequency through durability.

Overgrinding and Slime Generation

Excessive grinding creates unwanted ultra-fines. Slime coats mineral surfaces and hurts separation. It also raises reagent consumption.

Circuit control prevents overgrinding. Proper classification recycles coarse material quickly. Slime management protects downstream performance.

Conclusion

The grinding stage of ore processing determines mineral recovery and plant economics. Proper equipment selection, process control, and media management drive success.

Challenges persist but solutions through technology and expertise keep improving results. Mastering grinding remains essential for sustainable mining operations.

Frequently Asked Questions

How does grinding affect flotation performance?

Fine enough particles ensure mineral liberation while avoiding excess slime. Proper size distribution maximizes bubble-particle attachment and recovery.

What causes high energy use in grinding circuits?

Ore hardness, poor classification, and suboptimal media selection drive excess consumption. Circuit audits identify improvement areas.

Why choose high-chrome media over forged steel?

High-chrome offers better wear resistance and less contamination. It maintains shape longer for consistent grinding action.

How can plants reduce grinding costs?

Optimize media size, improve classification, and use predictive maintenance. Energy-efficient mill designs also lower operating expenses.