In the mining sector, the journey from the pit to the port is defined by a series of complex unit operations. While extraction brings the ore to the surface, it is the Mineral Processing Plant that unlocks the economic value of the resource. Transforming Run-of-Mine (ROM) ore into a marketable concentrate or refined metal requires a sophisticated suite of industrial machinery designed to crush, grind, classify, and separate minerals based on their physical and chemical properties.

For plant metallurgists and operations managers, selecting and maintaining this equipment is paramount. The efficiency of the circuit determines recovery rates, energy consumption, and overall Operating Expenses (OPEX). Furthermore, the performance of major capital equipment—particularly in the comminution circuit—is intrinsically linked to the quality of the consumables used, such as the grinding media provided by Alpha Grinding Media. This article provides a technical overview of the primary equipment categories utilized in modern mineral beneficiation.

1. Comminution Equipment: Size Reduction

Comminution is the most energy-intensive stage of mineral processing. Its primary objective is “liberation”—reducing the particle size of the ore until the valuable mineral grains are physically detached from the gangue (waste rock). This is achieved through a multi-stage process involving crushers and grinding mills.

Crushers (Primary to Tertiary)

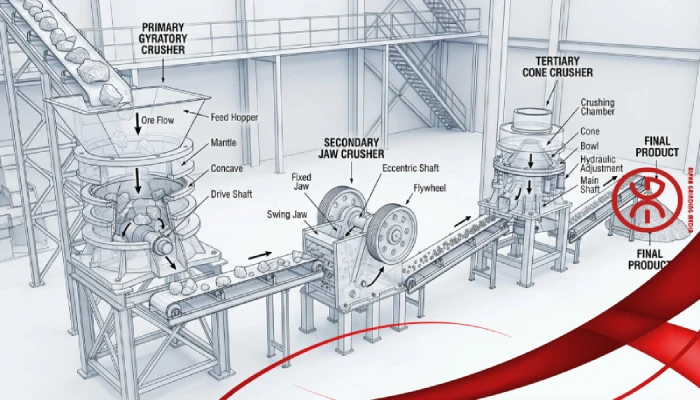

Crushing is typically a dry process and the first stage of size reduction. The equipment used here relies on compression and impact forces.

- Gyratory and Jaw Crushers: These are employed as primary crushers. They accept large ROM boulders directly from the mine trucks. Jaw crushers use a reciprocating plate to crush rock against a fixed plate, while gyratory crushers use a spinning mantle within a concave bowl.

- Cone Crushers: Used for secondary and tertiary crushing, these machines produce a finer product suitable for feeding into the grinding circuit. They operate at higher speeds and offer a higher reduction ratio than primary crushers.

Grinding Mills (Tumbling Mills)

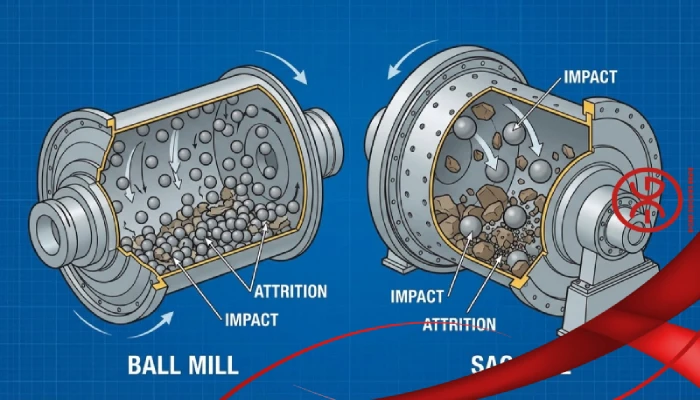

Once crushed to a gravel-like consistency, the ore enters the grinding circuit. This is usually a wet process where water is added to form a slurry.

- SAG (Semi-Autogenous Grinding) Mills: These large-diameter mills use the ore itself as the primary grinding media, often supplemented with a small percentage of large steel balls. They are effective for the initial stage of grinding.

- Ball Mills: The workhorse of the industry. Ball mills are long, cylindrical vessels filled with a charge of steel grinding balls. As the mill rotates, the balls tumble and cataract, pulverizing the ore through impact and attrition to a fine powder.

The Critical Role of Grinding Media

It is important to note that a Ball Mill is essentially just a rotating shell. The actual work of comminution is performed by the grinding media inside. This is where the expertise of Alpha Grinding Media becomes a decisive factor in plant performance.

The hardness, density, and wear resistance of the steel balls dictate the efficiency of the grind. High-quality grinding media ensures that the particle size distribution (PSD) remains consistent, preventing “over-grinding” (which creates slimes) or “under-grinding” (which leads to locked minerals). Therefore, the grinding media should not just be viewed as a consumable, but as a critical component of the milling equipment itself.

2. Sizing and Classification Equipment

In a continuous processing circuit, it is vital to ensure that only particles that have reached the target size proceed to the separation stage. Oversized particles must be returned to the mills for further grinding.

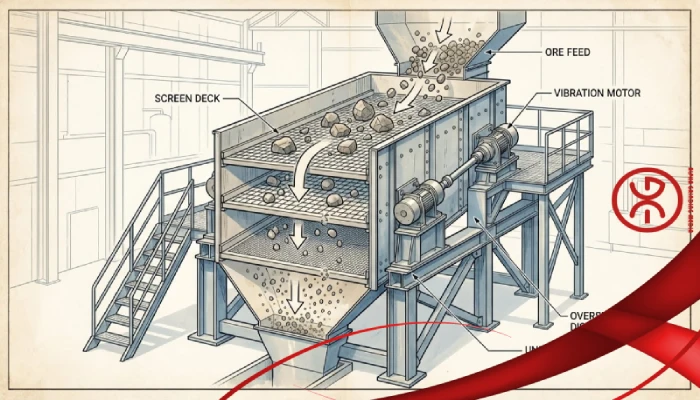

Vibrating Screens

Screens are mechanical decks that vibrate to separate particles based on size. They are primarily used in the crushing circuit to separate fine material that can bypass the crushers (scalping) or to ensure the final crushed product meets specifications.

Hydrocyclones

In the grinding circuit, hydrocyclones are the standard for classification. They have no moving parts and utilize centrifugal force to separate the slurry. The heavier, coarser particles are thrown to the walls and exit the bottom (underflow) to return to the Ball Mill, while the fine, liberated particles exit the top (overflow) and move on to separation. The efficiency of the cyclone is directly dependent on the consistency of the feed coming from the mill.

3. Separation (Beneficiation) Equipment

Once liberation is achieved, the plant employs separation equipment to isolate the valuable minerals. The choice of equipment depends entirely on the mineralogy of the ore.

Froth Flotation Cells

For sulphide ores (such as copper, lead, and zinc), froth flotation is the dominant technology.

- Mechanism: The equipment consists of large tanks or cells equipped with agitators and air injection systems. Reagents are added to make the valuable minerals hydrophobic. As air bubbles rise through the slurry, the minerals attach to them and float to the surface as a froth, which is skimmed off into launders.

- Equipment Types: Plants may use mechanical cells (with impellers) or column flotation cells (which use spargers and wash water) for cleaning stages.

Magnetic and Gravity Separators

For ores that have distinct density or magnetic properties (like iron ore or gold), different equipment is used.

- Magnetic Separators: These utilize rotating drums with powerful magnets to pull ferrous minerals out of the slurry stream.

- Gravity Concentrators: Equipment such as spiral concentrators, shaking tables, and centrifugal concentrators use gravity and water flow to separate heavy minerals from lighter gangue.

4. Dewatering and Solid-Liquid Separation

The product of the separation stage is a dilute slurry. To create a shippable product and to manage waste, water must be removed.

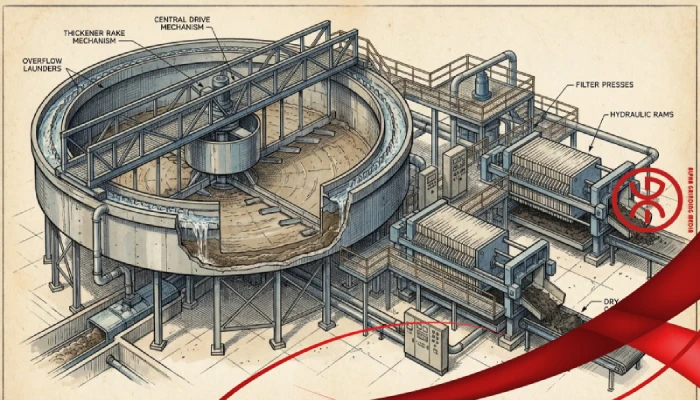

Thickeners

Thickeners are massive circular tanks where the slurry is fed into the center. Flocculants are added to clump the solids together, causing them to settle to the bottom. A rake mechanism moves the settled solids to a central discharge point, while clarified water overflows the top to be recycled back into the plant.

Filtration Units

For the final concentrate, thickener underflow is pumped to filters.

- Filter Presses: These use pressure to force water out of the slurry through filter cloths, creating a dry “cake.”

- Vacuum Filters: These use suction to draw water out of the slurry. The result is a concentrate with low moisture content, ready for transport to smelters.

5. Material Handling and Auxiliary Equipment

Connecting all these unit operations is a network of material handling equipment.

- Conveyors: Belt conveyors transport dry ore between crushers and stockpiles.

- Slurry Pumps: Heavy-duty centrifugal pumps move the abrasive slurry between mills, cyclones, and flotation cells.

- Reagent Feeders: Precision dosing pumps ensure the correct chemical balance in the flotation circuit.

Conclusion: The Synergy Between Machinery and Consumables

A Mineral Processing Plant is a synchronized system where every piece of equipment relies on the performance of the others. A highly efficient crushing circuit feeds a consistent product to the grinding circuit. A well-optimized grinding circuit—utilizing robust machinery and high-performance consumables like those from Alpha Grinding Media—delivers liberated particles to the separation circuit.

For industry professionals, understanding the capabilities and limitations of this equipment is essential. However, recognizing that the efficiency of massive mills often hinges on the quality of the grinding media within them is what separates standard operations from world-class processing plants. Investing in the right equipment and the right media is the foundation of a profitable mining operation.

Frequently Asked Questions

What is the main goal of comminution in mineral processing?

The primary goal is particle liberation—reducing ore size so valuable minerals detach from waste rock, enabling efficient downstream separation.

Why is grinding media quality important in ball mills?

High-quality grinding media ensures consistent particle size, reduces energy consumption, prevents over-grinding, and improves overall circuit efficiency.

What equipment is commonly used for mineral separation?

Depending on the ore type, flotation cells, magnetic separators, and gravity concentrators are used to separate valuable minerals from gangue.

What is the role of thickeners and filters in a processing plant?

They remove excess water from slurry, producing a transportable concentrate and recycling process water for improved efficiency.