In the global mining and cement sectors, the grinding process is often the most energy-intensive and costly stage of production. At the heart of this process lies the grinding media. Choosing the right media is not merely a procurement task; it is a critical engineering decision that dictates the efficiency of the entire circuit. Many...

Category: <span>Uncategorized</span>

A Comprehensive Glossary of Mining Terms

The mining industry operates with a specialized vocabulary that can often seem like a foreign language to outsiders. For investors, students, and professionals entering the field, having a reliable Glossary of Mining Terms is not just helpful—it is essential. From the initial geological survey to the final processing of materials, every stage of the mine...

Essential Equipment in Mineral Processing

In the mining sector, the journey from the pit to the port is defined by a series of complex unit operations. While extraction brings the ore to the surface, it is the Mineral Processing Plant that unlocks the economic value of the resource. Transforming Run-of-Mine (ROM) ore into a marketable concentrate or refined metal requires...

What Are Mine Tailings and How Are They Managed?

In the mining and mineral processing industry, the extraction of valuable commodities whether gold, copper, or iron ore is inextricably linked to the production of waste. While “waste rock” (overburden) constitutes the material moved to access the ore body, mine tailings represent a more complex challenge. Tailings are the fine-grained residue remaining after the uneconomic...

What Is Concentrate and How Is It Produced?

In the modern global food industry, efficiency, logistics, and quality assurance are paramount. Among the most strategically important raw materials are concentrates, substances from which water or other solvents have been deliberately removed. The concept of concentration has transformed the processing and transport of perishable goods, ensuring that seasonal harvests can be utilized worldwide throughout...

Beneficiation in Mining

Beneficiation in mining refers to the series of processes that transform raw ore into a concentrated product with higher economic value. This stage sits between extraction and final metal production. It removes impurities and separates valuable minerals from waste rock. In modern mining operations, beneficiation plays a critical role in determining profitability. Without effective processing,...

How Much Grinding Media Does a Mill Need?

If you’re running a mining operation, a ceramics plant, or even a small lab setup, figuring out the right amount of grinding media for your mill can make all the difference in efficiency and costs. Grinding media. the balls, rods, or beads that do the heavy lifting inside the mill. are essential for breaking down...

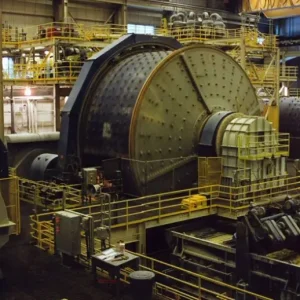

How Do Ball Mills Work?

Welcome to the Alpha Grinding Media blog; your primary source for understanding the essential machinery that powers modern industry. Today, we are going to unveil a cornerstone of material processing: the ball mill. You have likely seen these large, rotating cylinders at industrial sites, but what exactly happens inside them? How does a simple rotating...

SAG Mills: A Comprehensive Guide to Semi-Autogenous Grinding

Semi-autogenous grinding (SAG) mills are powerhouse machines in the mining industry, designed to crush and grind large ore particles into finer sizes for further processing. These mills combine the power of impact and attrition to process high volumes of material, making them essential for large-scale operations like gold, copper, and iron ore mining. This guide...

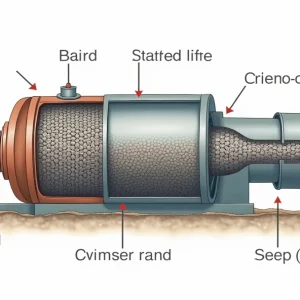

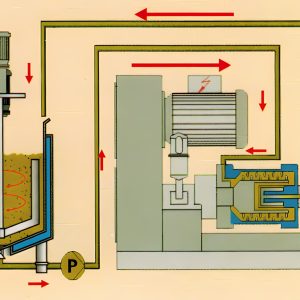

Sand Mills: A Comprehensive Guide to Fine Grinding Technology

Sand mills are advanced grinding machines designed for ultra-fine particle size reduction, widely used in industries like paints, coatings, inks, and chemicals. These high-efficiency mills excel at producing uniform, nano-scale particles, making them essential for applications requiring smooth textures and consistent quality. This article from Alpha Grinding Media examines sand mills, how they work, their...

- 1

- 2