Beneficiation in mining refers to the series of processes that transform raw ore into a concentrated product with higher economic value. This stage sits between extraction and final metal production. It removes impurities and separates valuable minerals from waste rock.

In modern mining operations, beneficiation plays a critical role in determining profitability. Without effective processing, even rich deposits may become uneconomical. The goal is to increase the grade of the ore while minimizing material loss. This guide from alpha grinding media explores every aspect of beneficiation in mining processing for professionals seeking deeper technical understanding.

The Fundamentals of Beneficiation

At its core, beneficiation involves physical and sometimes chemical methods to upgrade ore quality. The process begins immediately after mining and continues until the material is ready for smelting or further refining.

Ore characteristics dictate the approach. Particle size, mineral composition, density differences, and magnetic properties all influence method selection. Successful beneficiation requires careful planning based on detailed geological surveys and laboratory testing. Engineers must balance recovery rates with operational costs throughout the workflow.

Key Steps in the Beneficiation Process

Every beneficiation circuit follows a logical sequence of unit operations. Each step builds on the previous one to progressively improve concentrate quality.

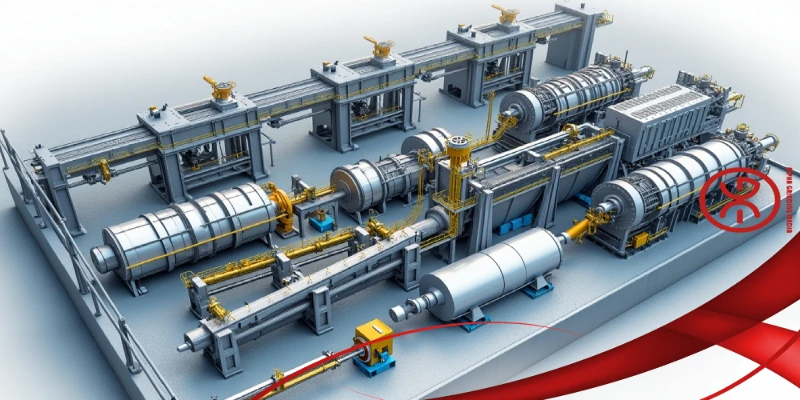

Crushing and Grinding

The journey starts with size reduction. Large rocks from the mine face must be broken down to liberate mineral particles. Jaw crushers handle initial coarse breaking, followed by cone crushers for intermediate stages.

Grinding mills reduce material to fine particles, typically between 30 and 150 microns, depending on the downstream process. The finer the grind, the better the liberation, but energy consumption rises sharply. ALPHA GRINDING MEDIA offers high-performance balls that maintain consistent size and shape, optimizing energy use during this critical phase.

Screening and Classification

After grinding, particles are separated by size. Vibrating screens remove oversize material for re-crushing. Classifiers like hydrocyclones sort fines into different streams based on settling velocity.

Proper classification prevents over-grinding of already liberated particles. It also ensures downstream processes receive material within their optimal size range. Modern plants use automated systems to maintain tight control over cut points.

Separation Techniques

This stage exploits physical differences between minerals. Density, magnetism, surface properties, and electrical conductivity all become tools for separation. Multiple methods often combine in sequence to achieve target grades.

Common Methods of Beneficiation in Mining Processing

Different ores require different approaches. The choice depends on mineralogy and desired end product.

Gravity Separation

One of the oldest and simplest methods. It uses density differences to separate heavy minerals from lighter gangue. Jigs, shaking tables, and spiral concentrators are common equipment.

Gravity methods work best for coarse particles and high-density contrasts. They consume little energy and produce no chemical waste. Tin, tungsten, and gold operations frequently rely on gravity circuits as primary concentration steps.

Magnetic Separation

Effective when target minerals respond to magnetic fields. Dry or wet drum separators remove magnetite from iron ore or separate ilmenite from beach sands.

High-intensity rare earth magnets have expanded applications. They can now recover weakly magnetic minerals that older systems missed. Intensity and drum speed must be precisely controlled for optimal results.

Flotation

The dominant method for sulfide ores and many industrial minerals. It creates hydrophobic surfaces on valuable particles using collectors and frothers. Air bubbles attach to these particles and carry them to the surface as froth.

Froth flotation requires careful pH control and reagent dosing. Circuit design includes rougher, cleaner, and scavenger stages. Copper, lead, zinc, and phosphate plants depend heavily on well-tuned flotation systems.

Electrostatic and Other Advanced Methods

High-tension roll separators handle conductive versus non-conductive minerals. They work well for beach sand processing to recover zircon and rutile.

Emerging technologies include sensor-based sorting using X-ray transmission or near-infrared spectroscopy. These systems identify and eject waste particles before bulk processing, reducing downstream loads.

Advantages of Beneficiation in Mining

Proper beneficiation delivers multiple benefits across the value chain.

First, it increases concentrate grade. Shipping high-grade material reduces transportation costs dramatically. A copper concentrate at 30% versus raw ore at 1% means 30 times less mass to move.

Second, it enables economic extraction from lower-grade deposits. As high-grade ores deplete, beneficiation keeps marginal projects viable.

Third, it improves environmental performance. Removing waste early means less material enters tailings dams. Higher recovery rates also reduce the footprint of mining operations.

Challenges and Limitations in Beneficiation Processes

Despite advantages, beneficiation faces significant hurdles.

Fine grinding consumes massive energy. In some operations, size reduction accounts for 50% of total power usage. Wear on equipment adds maintenance costs.

Complex mineralogy creates separation difficulties. Intergrown particles resist liberation regardless of grind size. Selectivity suffers when valuable and gangue minerals share similar properties.

Water management poses another challenge. Many processes require large volumes, and recycling becomes essential in arid regions. Chemical reagents in flotation circuits demand careful handling and disposal.

Applications and Examples of Beneficiation in Real-World Mining

Iron ore processing provides a classic example. Hematite and magnetite ores undergo crushing, grinding, and magnetic separation to produce concentrates above 65% Fe.

Gold beneficiation often combines gravity concentration with cyanidation. Free-milling ores may achieve 90% recovery through simple circuits, while refractory ores need additional pre-treatment.

Diamond mines use dense media separation to recover gems from kimberlite. X-ray sorters then identify diamonds by their luminescence for final hand sorting.

Conclusion

Beneficiation in mining remains essential for economic and sustainable resource development. It transforms low-value rock into high-value concentrate while addressing environmental concerns.

As ore grades decline and environmental standards tighten, efficient processing becomes even more critical. Operations that master beneficiation principles will maintain competitive advantage in the coming decades. The integration of advanced technology with sound metallurgical practice defines the future of mining processing.

Frequently Asked Questions

How does beneficiation differ from mineral processing?

Beneficiation is often considered part of mineral processing, focusing primarily on concentration and upgrading steps before metallurgical extraction. Mineral processing includes all steps from mine to metal, while beneficiation specifically upgrades ore before smelting.

What factors determine the choice of beneficiation method?

Ore mineralogy, particle size, liberation characteristics, and economic considerations all influence method selection. Laboratory testing and pilot plants provide data for final circuit design.

Can beneficiation improve recovery from low-grade ores?

Yes, advanced methods like fine grinding and multi-stage flotation enable economic recovery from ores previously considered waste. Grade-recovery curves guide optimization.

How does grinding media affect overall beneficiation costs?

Superior media reduces energy consumption and downstream reagent use. Though initial cost may be higher, total operating expenses decrease through improved efficiency and longer campaigns.