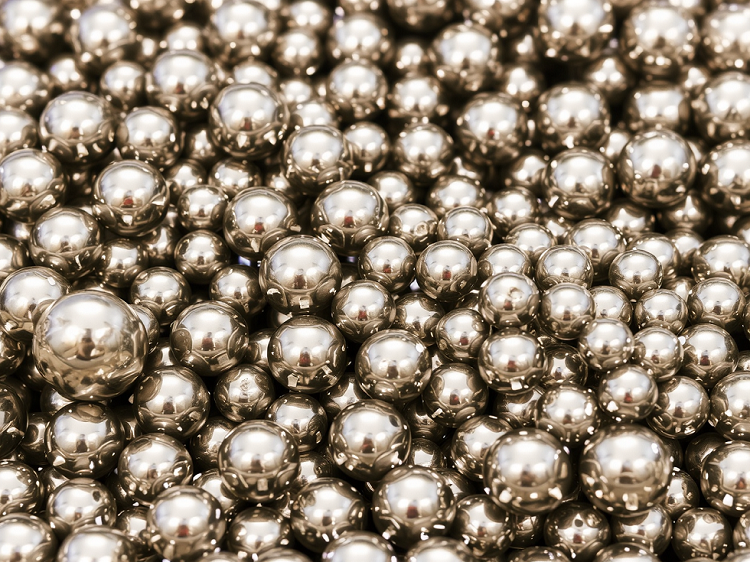

Round metal balls, often referred to as steel balls, have become essential components across various industrial sectors and technologies. Their unique properties, including high hardness, durability, and resistance to wear, make them indispensable in numerous applications. This article delves into the application of round metal balls, exploring their manufacturing processes, engineering innovations, technological developments, environmental considerations, and future trends.

Manufacturing Processes Utilizing Metal Balls

The production of round metal balls typically involves three primary methods: casting, forging, and rolling.

Casting: This is one of the oldest manufacturing processes, where molten metal is poured into molds to achieve the desired shape. Casting allows for the production of balls in various sizes and materials, including high-carbon steel and stainless steel. The quality of the cast balls can vary based on the casting method and the cooling process.

Forging: In this process, metal is shaped by applying compressive forces, resulting in balls with improved mechanical properties. Forged steel balls are known for their high strength and durability, making them ideal for applications in high-load environments.

Rolling: This method involves passing metal through rollers to achieve a uniform thickness and shape. Rolling can produce high-precision balls with excellent surface finish and dimensional accuracy, suitable for high-performance applications such as bearings.

These manufacturing processes ensure that round metal balls meet the specific requirements of their intended applications, whether in industrial machinery, automotive components, or consumer products.

Engineering Applications and Innovations

Round metal balls find applications in various engineering domains, including:

Bearings: Steel balls are crucial components in ball bearings, enabling smooth rotation and reducing friction in machinery. Their ability to withstand high loads and operate at varying speeds makes them indispensable in automotive engines, electric motors, and industrial equipment.

Valves: Metal balls are used in ball valves to control the flow of fluids and gases in pipelines. Their spherical shape allows for tight seals and efficient flow control, making them ideal for use in oil, natural gas, and chemical processing industries.

Grinding Media: In the cement and mining industries, round metal balls serve as grinding rods in ball mills. They enhance the efficiency of material grinding, contributing to the production of finely ground materials.

Recent innovations in engineering have focused on improving the performance and longevity of metal balls through advanced materials and coatings, resulting in reduced wear and increased resistance to corrosion.

Use in Technology and Development

The applications of round metal balls extend to various technological developments:

Robotics: In robotics, steel balls are used in linear motion systems, such as linear guides and ball screws, providing smooth movement and precise positioning in automated systems.

Consumer Products: Many everyday items, including spray cans and toy manufacturing, utilize metal balls for functional purposes. In spray cans, metal balls help mix the contents for an even spray, while in toys, they enhance playability and durability.

Scientific Research: In physics experiments, round metal balls are often used to study concepts such as potential and kinetic energy, friction, and rotational inertia. Their uniform shape and weight make them ideal for conducting experiments.

The ongoing development of new technologies continues to expand the application of round metal balls in innovative ways, enhancing their role in both industrial and consumer markets.

Environmental Considerations in Metal Ball Production

As the demand for round metal balls increases, so do the environmental considerations associated with their production.

Sustainability: The manufacturing processes for metal balls can generate waste and emissions, making it essential for companies to adopt sustainable practices. This includes using eco-friendly materials, optimizing production processes to minimize waste, and implementing recycling programs for metal scrap.

Energy Consumption: Manufacturing methods such as forging and rolling can be energy-intensive. Companies are increasingly investing in energy-efficient technologies and practices to reduce their carbon footprint and overall energy consumption.

Manufacturers are also encouraged to comply with environmental regulations and standards to ensure responsible production practices. The development of more sustainable manufacturing processes will play a critical role in the future of the metal ball industry.

Future Trends and Potential Applications

The future of round metal balls is promising, with several trends and potential applications on the horizon:

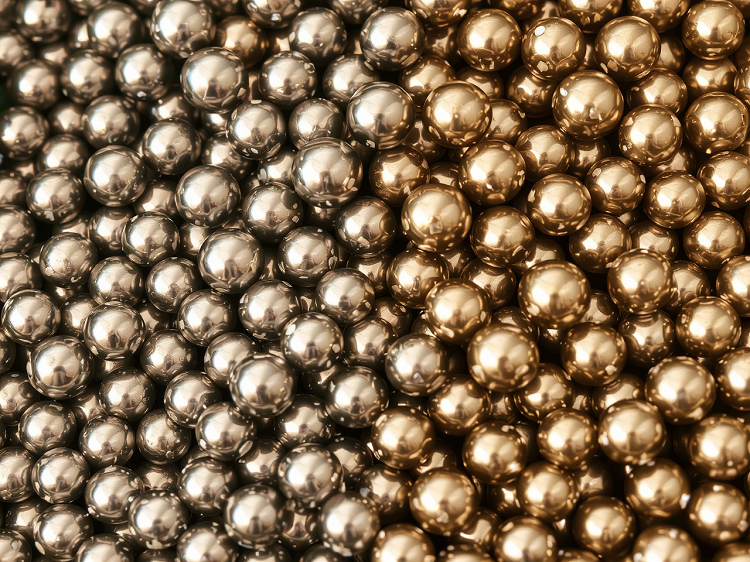

Advanced Materials: Research into new materials, such as composites and alloys, may lead to the production of metal balls with enhanced properties, including reduced weight, increased strength, and improved resistance to corrosion and wear.

Smart Technologies: The integration of smart technologies into industrial applications may also drive innovation in metal ball applications. For instance, sensors embedded in metal balls could provide real-time data on performance and wear, facilitating predictive maintenance in machinery.

New Industries: Emerging industries, such as renewable energy and electric vehicles, present new opportunities for the application of round metal balls. Their use in energy storage systems and electric motor components may become increasingly prevalent.

To learn more about high-quality round metal balls for various applications, including grinding rods, consider reaching out to Alpha Grinding Media. They provide comprehensive solutions and information for industries seeking reliable metal ball products.

FAQ

Round metal balls are used in various applications, including bearings, valves, grinding media in mills, and consumer products like spray cans and toys.

Round metal balls are produced through casting, forging, and rolling, each method providing unique advantages in terms of material properties and applications.

Manufacturers can adopt sustainable practices by using eco-friendly materials, optimizing production processes to reduce waste, and implementing recycling programs for scrap metal.

For high-quality round metal balls, including grinding rods, you can contact Alpha Grinding Media, a leading supplier offering a wide range of metal ball products for various industries.

This comprehensive overview highlights the diverse applications and importance of round metal balls in modern industry and technology. Their ongoing evolution and innovation promise to shape their role in future developments across various sectors.